A single-mode laser based on high-order surface grating

A surface grating, laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve problems such as unfavorable practical application, complicated laser electrical control system, etc., and achieve easy and precise control, good single-mode performance, and lower threshold gain. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

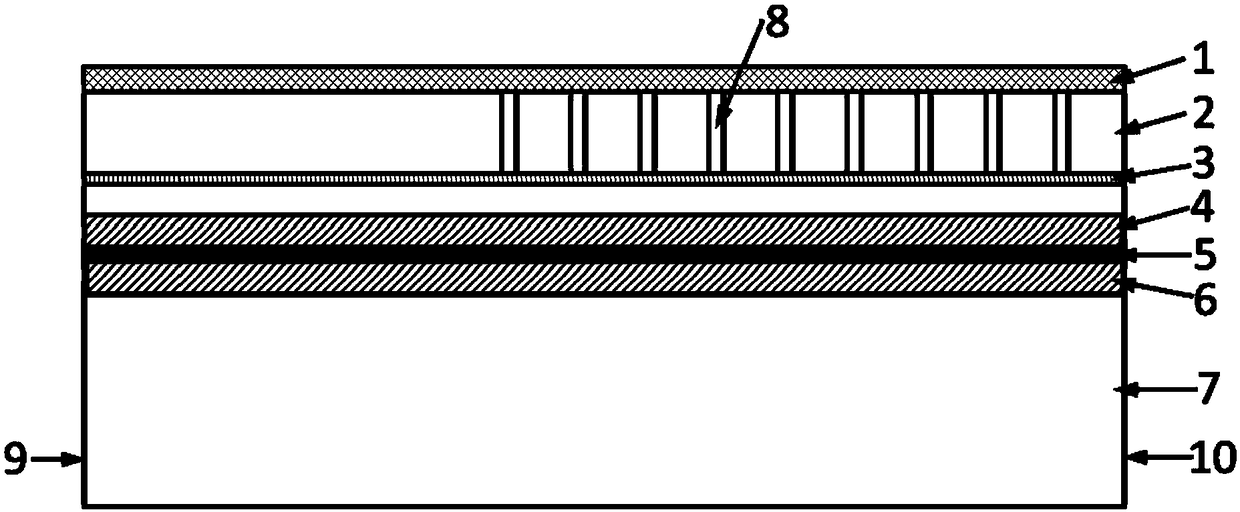

[0032] Such as figure 1 As shown, the single-mode laser based on the high-order surface grating of the present invention is a ridge waveguide structure, and the horizontal direction includes an electrode contact layer 1, a cover layer 2, an etching stop layer 3, an upper optical confinement layer 4, and a quantum well layer. 5. The lower optical confinement layer 6 and the substrate 7, wherein the upper optical confinement layer 4, the quantum well layer 5 and the lower optical confinement layer 6 constitute a waveguide core layer. A high-order Bragg grating 8 with a narrow groove width is etched on the surface of the ridge region near the output end of the laser, and the end face is coated with an anti-reflection film 9 ; the other end face of the laser is etched deeply to form 10 .

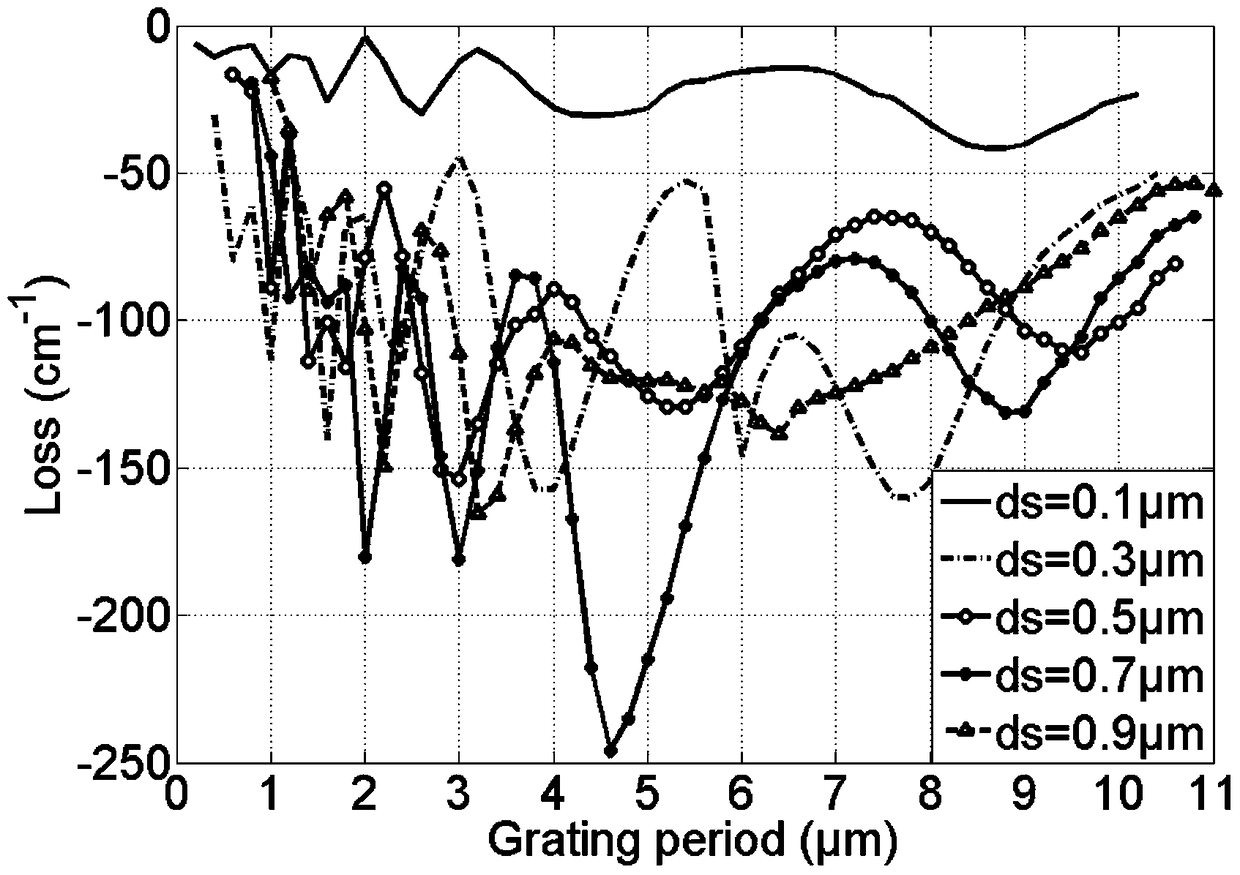

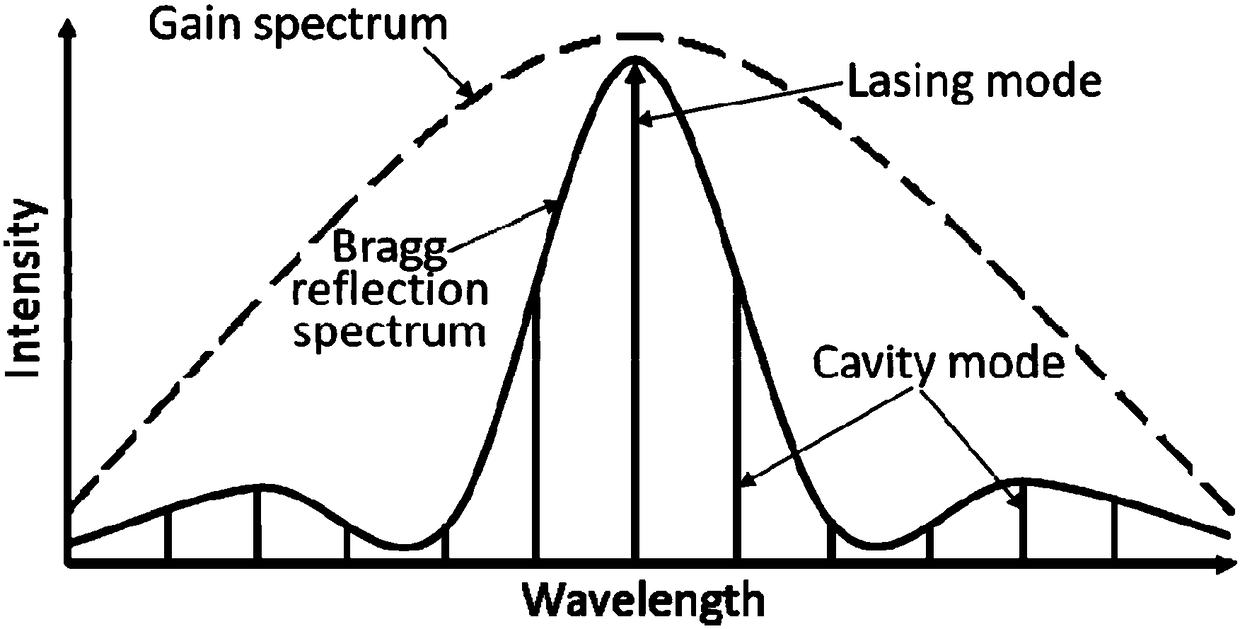

[0033] The grating is a Bragg reflection grating, and its period Λ is calculated according to the following formula:

[0034]

[0035] Among them, m is the grating order, λ is the Bragg wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com