Production process of efficient multi-layer brazed diamond saw blade

A technology of diamond saw blade and production process, which is applied in the direction of metal sawing equipment, stone processing equipment, stone processing tools, etc., can solve the problems of low surfacing welding efficiency, large gap, uncontrollable dimensional accuracy, etc., to improve work efficiency, The effect of high strength and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

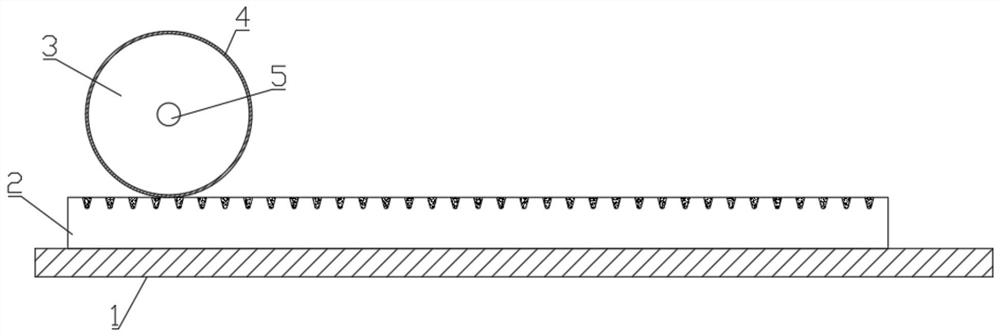

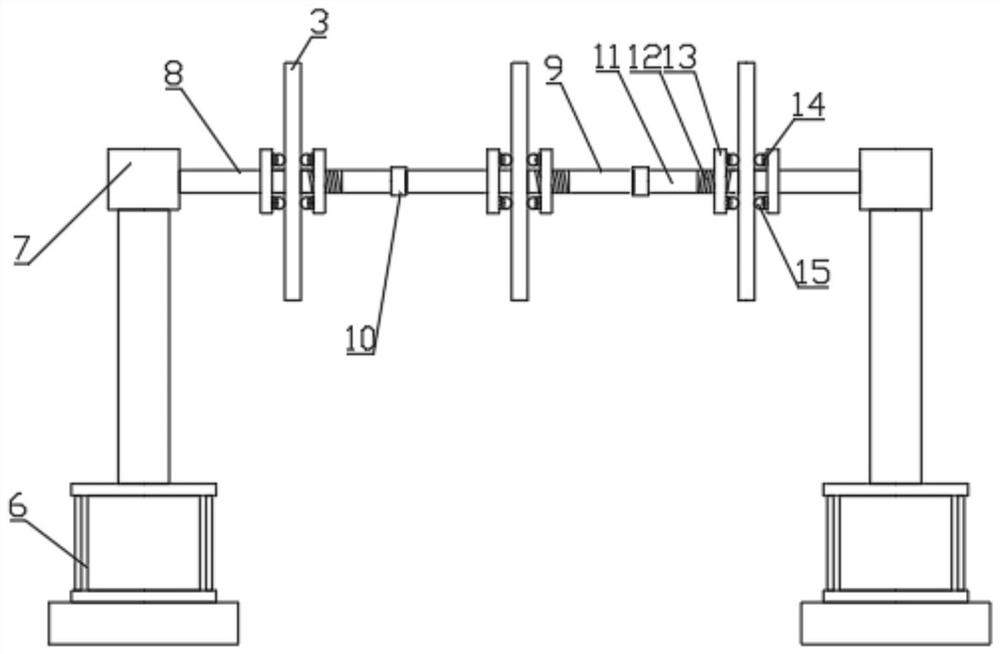

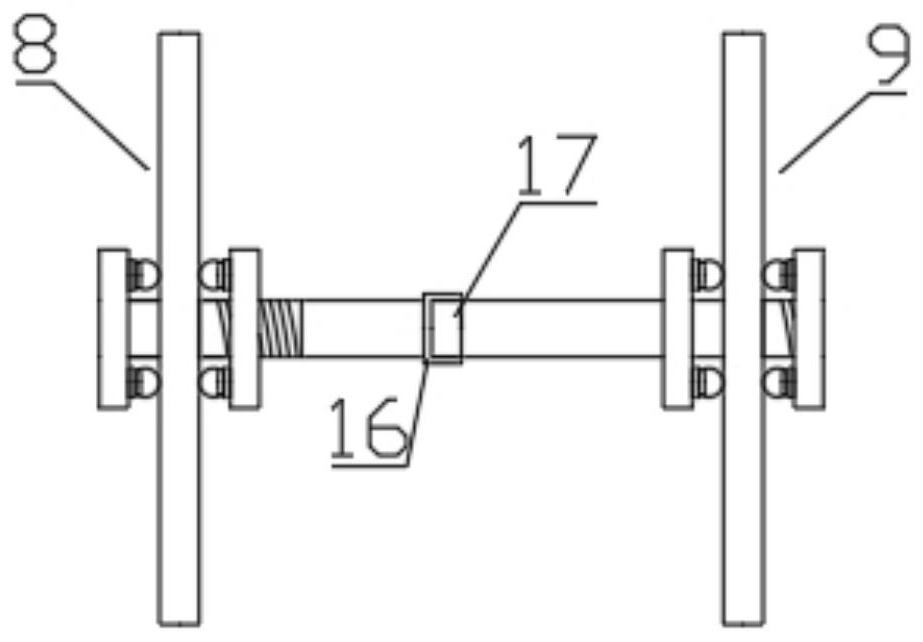

[0030] A production process of high-efficiency multi-layer brazing diamond saw blades, comprising the following steps:

[0031] The first step: prepare the abrasive block; add the raw materials of the abrasive block to the stainless steel reaction kettle and mix for 2 hours; the abrasive block is composed of the following raw materials: alloy powder, diamond and phenolic resin powder; the mass ratio of alloy powder, diamond and phenolic resin powder The ratio is 90:20:5; the alloy powder is composed of the following raw materials in parts by weight: 35 parts of silver powder, 35 parts of copper powder, and 5 parts of titanium powder; the particle size of the phenolic resin powder is -300 mesh;

[0032] The inner wall of the stainless steel reactor is provided with a release agent, and a layer of isolation film is applied on the inner wall of the stainless steel reactor through the release agent, which can prevent the abrasive block from sticking to the inner wall of the stainle...

Embodiment 2

[0037] A production process of high-efficiency multi-layer brazing diamond saw blades, comprising the following steps:

[0038] The first step: prepare the abrasive block; add the raw materials of the abrasive block to the stainless steel reaction kettle and mix for 2 hours; the abrasive block is composed of the following raw materials: alloy powder, diamond and phenolic resin powder; the mass ratio of alloy powder, diamond and phenolic resin powder 105:30:10; the alloy powder is composed of the following raw materials in parts by weight: 35-50 parts of silver powder, 35-60 parts of copper powder, 5-15 parts of titanium powder; the particle size of the phenolic resin powder is -300 mesh;

[0039] The inner wall of the stainless steel reactor is provided with a release agent, and a layer of isolation film is applied on the inner wall of the stainless steel reactor through the release agent, which can prevent the abrasive block from sticking to the inner wall of the stainless ste...

Embodiment 3

[0044] A production process of high-efficiency multi-layer brazing diamond saw blades, comprising the following steps:

[0045] The first step: prepare the abrasive block; add the raw materials of the abrasive block to the stainless steel reaction kettle and mix for 2 hours; the abrasive block is composed of the following raw materials: alloy powder, diamond and phenolic resin powder; the mass ratio of alloy powder, diamond and phenolic resin powder The ratio is 120:40:15; the alloy powder is composed of the following raw materials in parts by weight: 35-50 parts of silver powder, 35-60 parts of copper powder, 5-15 parts of titanium powder; the particle size of phenolic resin powder is -300 mesh;

[0046] The inner wall of the stainless steel reactor is provided with a release agent, and a layer of isolation film is applied on the inner wall of the stainless steel reactor through the release agent, which can prevent the abrasive block from sticking to the inner wall of the stai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com