Laser marking device and laser marking method for flame-retardant cable

A laser marking and cable technology, applied in the field of laser marking, can solve the problems of destroying the flame retardancy of flame-retardant cables, unenvironmental protection of coding, poor adhesion, etc., and achieve full life cycle traceability and color contrast threshold Enhanced and fast warehousing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

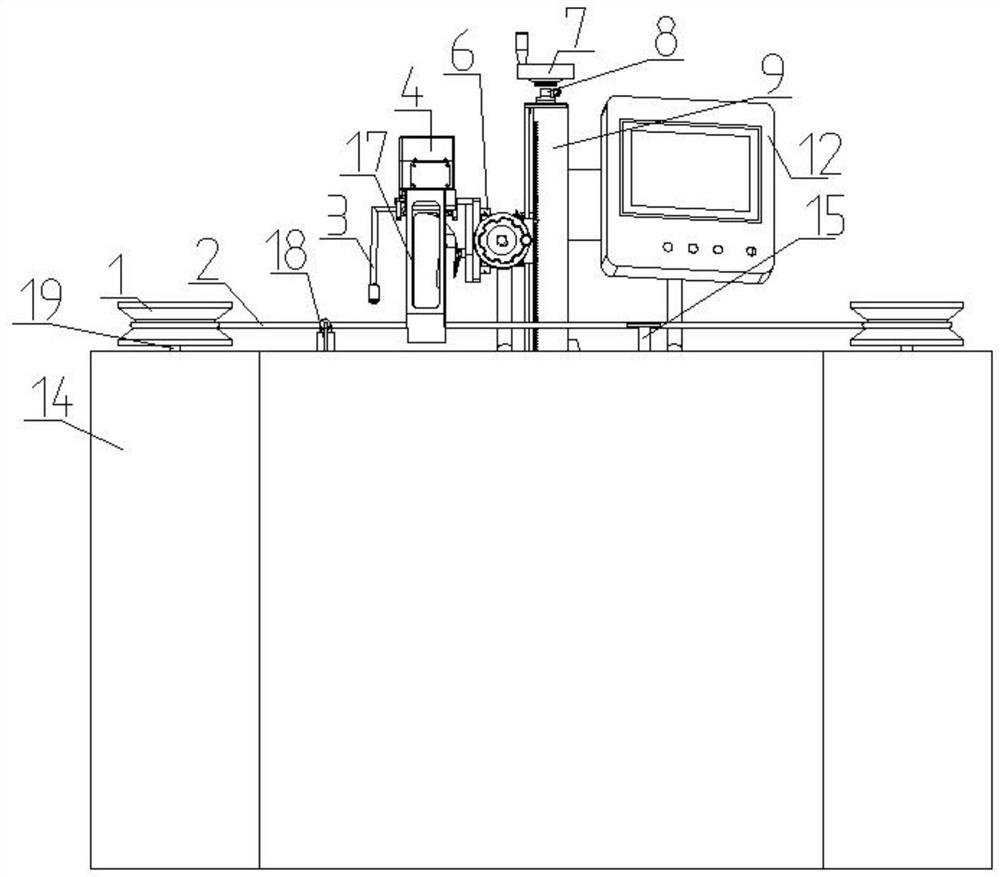

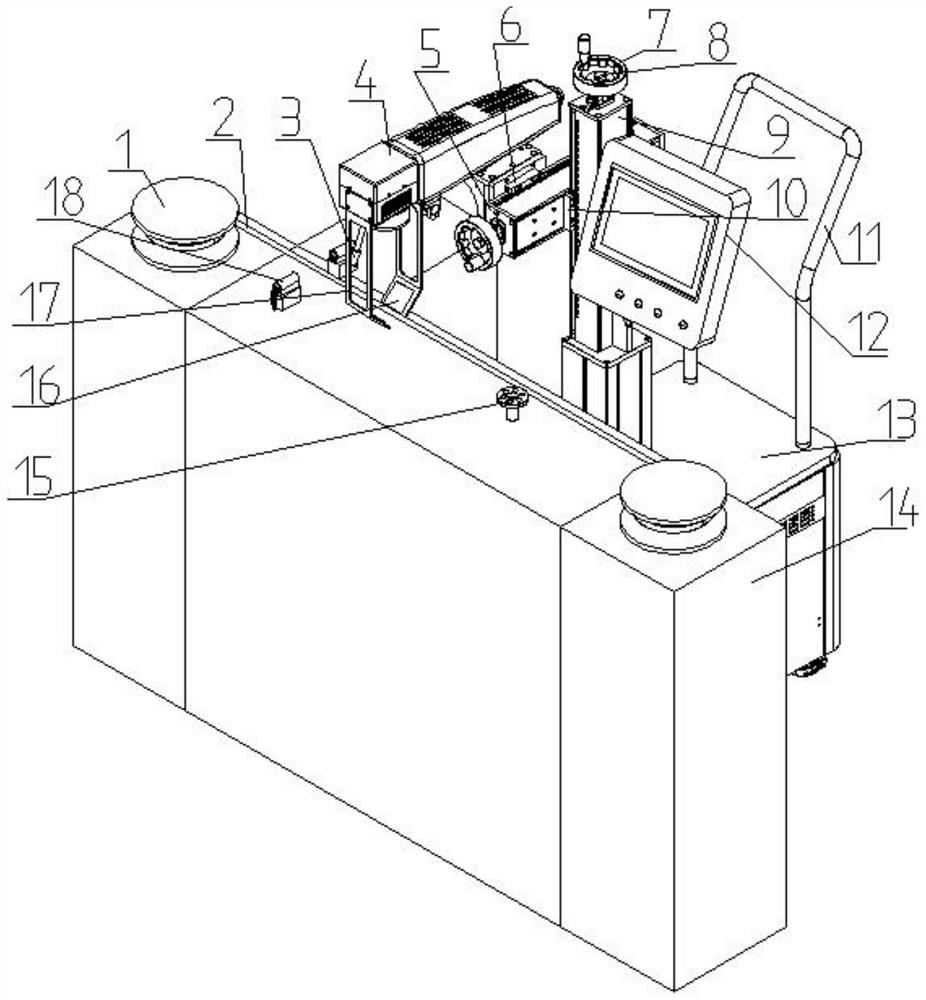

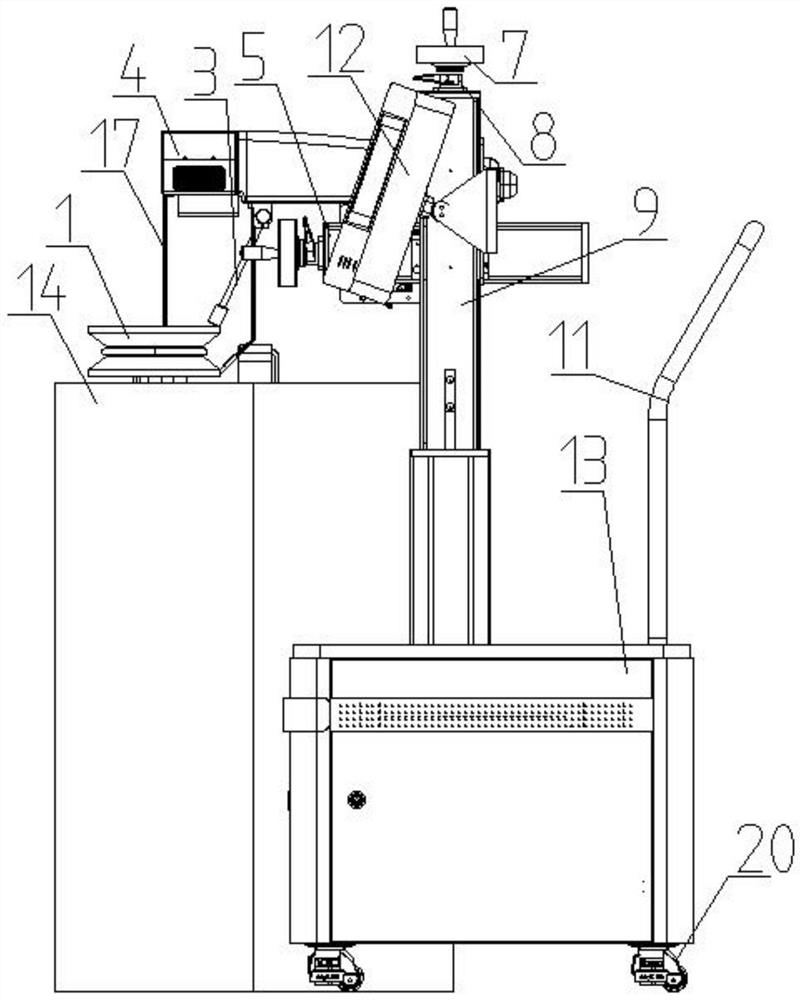

[0024] Example 1, such as Figures 1 to 5 As shown, the present invention is a flame-retardant cable laser marking device, including a workbench 14, on which a conveying device for conveying a flame-retardant cable 2 containing laser laser powder in the cable sheath is installed, and the flame-retardant The top of the cable 2 is provided with a marking head 4, and the front and rear sides of the flame-retardant cable 2 are provided with reflectors 16 inclined at 45 degrees to the horizontal plane. The reflector 16 is installed at the bottom of the marking head 4, and the marking head 4 is connected There are front and rear adjustment devices, the front and rear adjustment devices are connected with up and down adjustment devices, and the bottom of the up and down adjustment devices is fixed on the fiber laser marking machine cabinet 13.

[0025] The front end of marking head 4 is fixed with two mounting frames 17, and the bottom of mounting frame 17 is turned inwardly, and the...

Embodiment 2

[0039] Embodiment 2 is a laser marking method for a flame-retardant cable, which includes the following steps, S1, uniformly adding laser laser powder when the flame-retardant cable 2 is formed, S2, placing the flame-retardant cable 2 on the conveying device, and then The marking head 4 of the fiber laser marking device emits laser light, and the laser beam is emitted to the double-sided mirror 16, and the laser reflected by the mirror 16 performs laser marking on both sides of the flame-retardant cable, and the laser marking of the flame-retardant cable The laser laser powder in the area quickly absorbs the laser, and there is a color difference with the original material. Laser marking is realized on the flame-retardant cable. S3, the marked flame-retardant cable is rolled up and put into storage.

[0040] In step S1, the laser laser powder accounts for 0.1%-0.2% of the total weight of the total flame-retardant cable coating, and the fiber laser marking device in the step S2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com