Method for improving sterilization effect of ship ballast water based on microwave radiation activated C/CuO-Oxone composite system

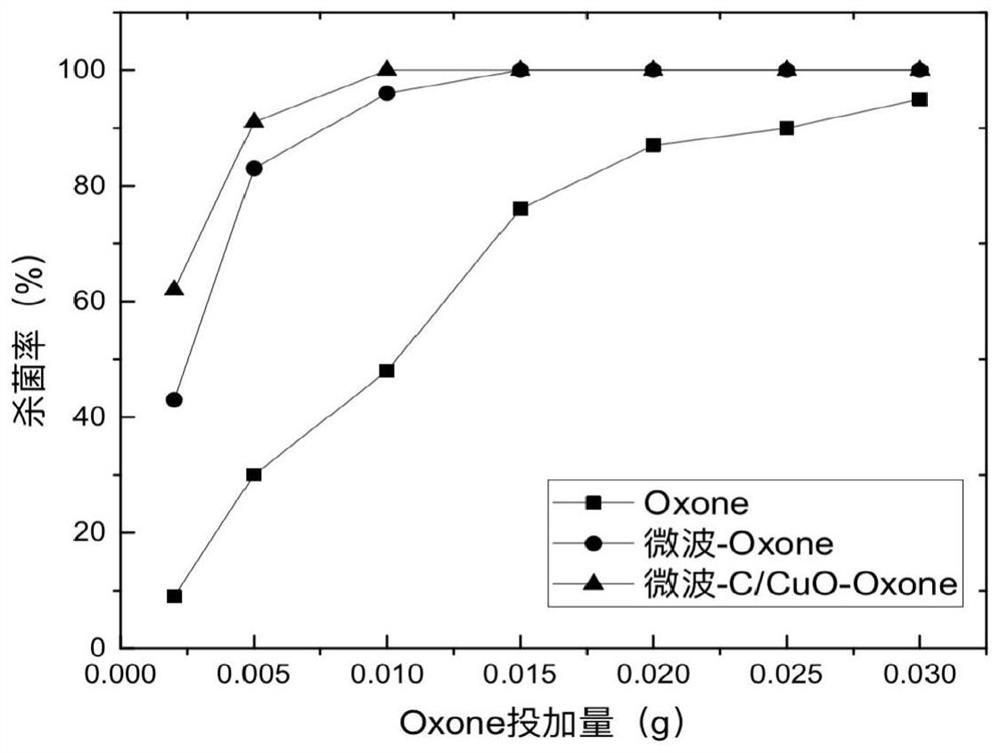

A technology of ship ballast water and microwave radiation, applied in chemical instruments and methods, oxidized water/sewage treatment, sterilization/microdynamic water/sewage treatment, etc., can solve the problems of disinfection by-products, secondary pollution, reaction Long time and other problems, to solve the effect of long reaction time, less dosage, simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

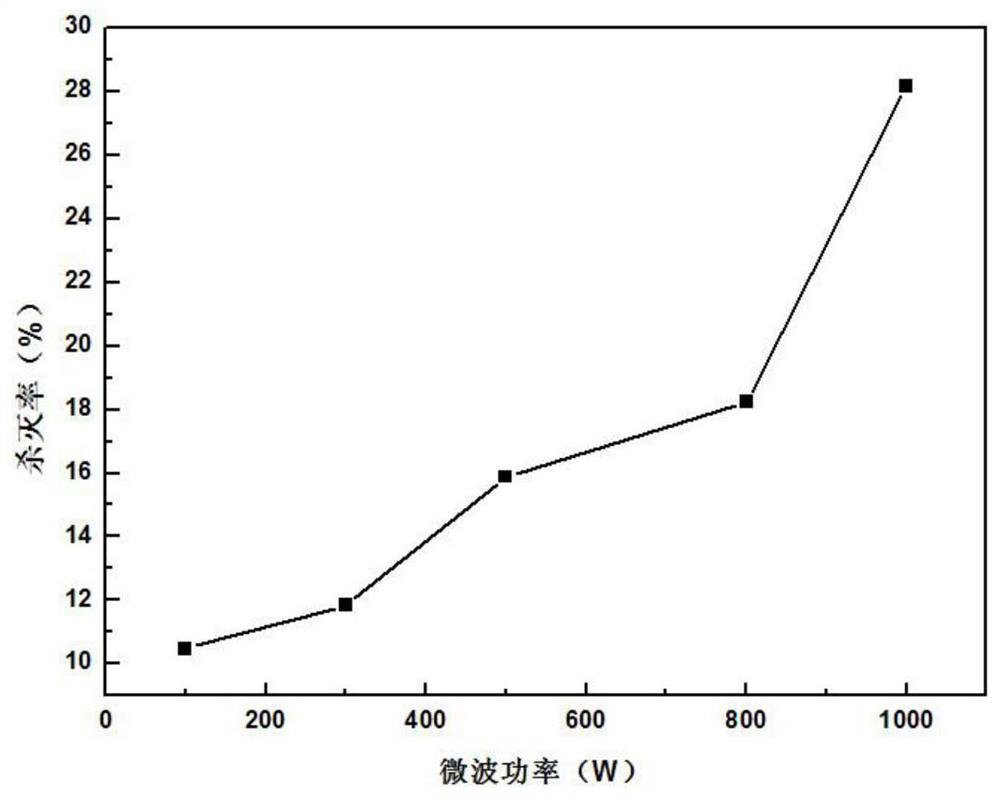

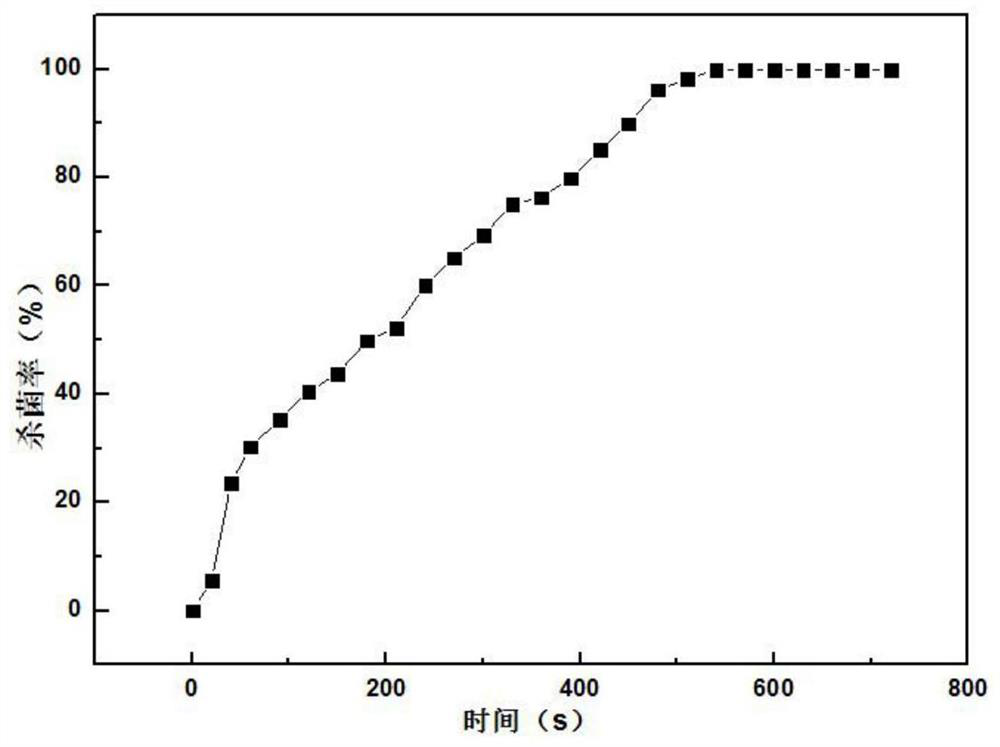

[0036] Add 1500g of C / CuO composite material and 1.5g of Oxone reagent to 100L of ship ballast water. After mixing evenly, use a microwave device to treat the ballast water. The microwave power is 1000W. Adjust the flow rate of the ballast water so that the ballast water flows through the microwave reaction. The timer time is 60s.

Embodiment 2

[0038] Add 1000g C / CuO composite material and 1.0g Oxone reagent to 100L ship ballast water. After mixing evenly, treat the ballast water with a microwave device. The microwave power is 800W. Adjust the flow rate of the ballast water so that the ballast water flows through the microwave reaction. The timer time is 60s.

Embodiment 3

[0040] Add 2000g C / CuO composite material and 0.8g Oxone reagent to 100L ship ballast water. After mixing evenly, use a microwave device to treat the ballast water. The microwave power is 500W. Adjust the flow rate of the ballast water so that the ballast water flows through the microwave reaction. The timer time is 50s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com