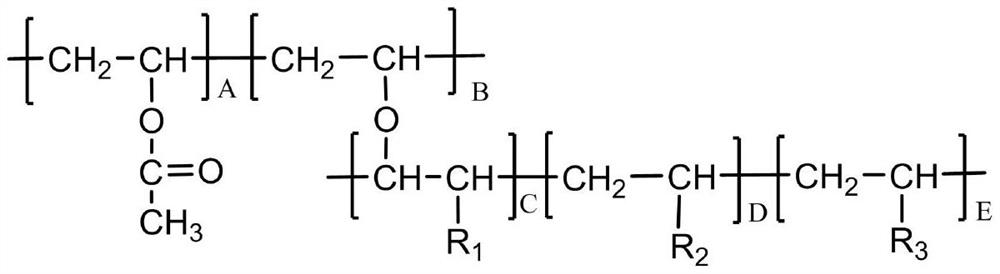

A kind of viscosity modifier for oil displacement and preparation method thereof

A viscosity modifier and oil displacement technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of chemical agents not working, prone to chromatographic separation, and huge difference in molecular weight, etc., to achieve thickening of the water phase Significantly, the viscosity of the oil phase is significantly reduced, and the effect of reducing the viscosity of the oil phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 4g of polyvinyl alcohol was dissolved in water, 8g acrylamide, 2g N-isopropyl acrylamide, 1.6g phenoxyacetate were added sequentially, 0.075g of potassium persulfate was dissolved in water, stirred until completely dissolved and then added to the polyvinyl alcohol solution, continuously stirred and introduced nitrogen during the addition process; the oil bath was heated to 40 °C, and 0.2g of hydroquinone was added after the reaction was 4h, and the ethanol precipitation, filtration and drying could obtain graft copolymerization products.

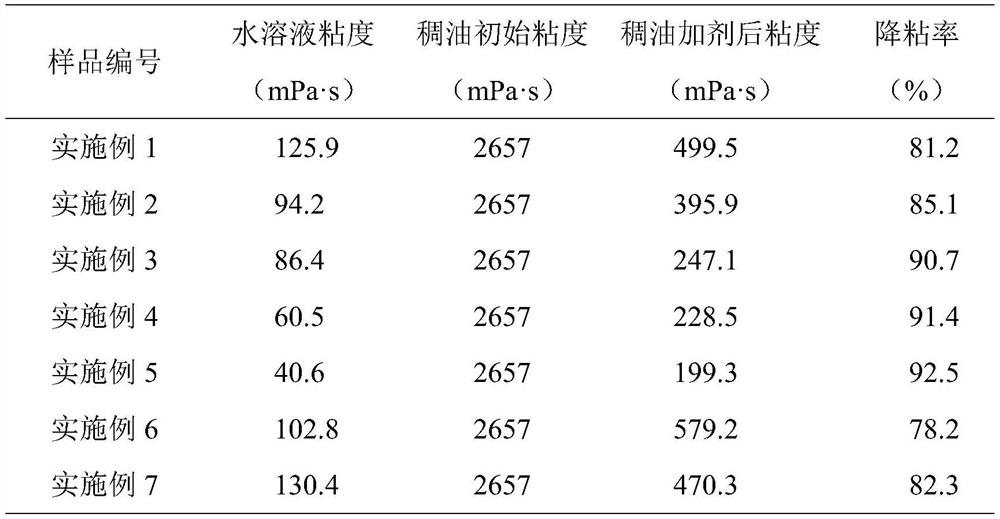

[0025] The prepared viscosity regulator was configured with deionized water into an aqueous solution with a mass concentration of 1%, and its viscosity at 80 °C was tested by a rotary viscometer, and the results were shown in Table 1;

[0026] The viscosity of crude oil at 80 °C was tested by rotary viscometer, and the results were shown in Table 1;

[0027] The prepared viscosity regulator was configured with deionized water into an aque...

Embodiment 2

[0034] The preparation method and test method of the viscosity regulator described in Example 1, the difference is that: the dosage of acrylamide is 7g, and the amount of allyl phenoxyacetate is 1.8g. The test results are shown in Table 1.

Embodiment 3

[0036] The preparation method and test method of the viscosity regulator described in Example 1, the difference is that: the amount of acrylamide is 6g, and the amount of allyl phenoxyacetate is 2.0g. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com