Thermal battery cable connection structure used in environment of 450 DEG C

A connection structure, thermal battery technology, applied in the direction of structural parts, insulated cables, battery pack components, etc., can solve problems such as falling off, loose cables and terminals, thermal battery can not be reliable power, etc., to achieve the integrity of the insulation layer, connection firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

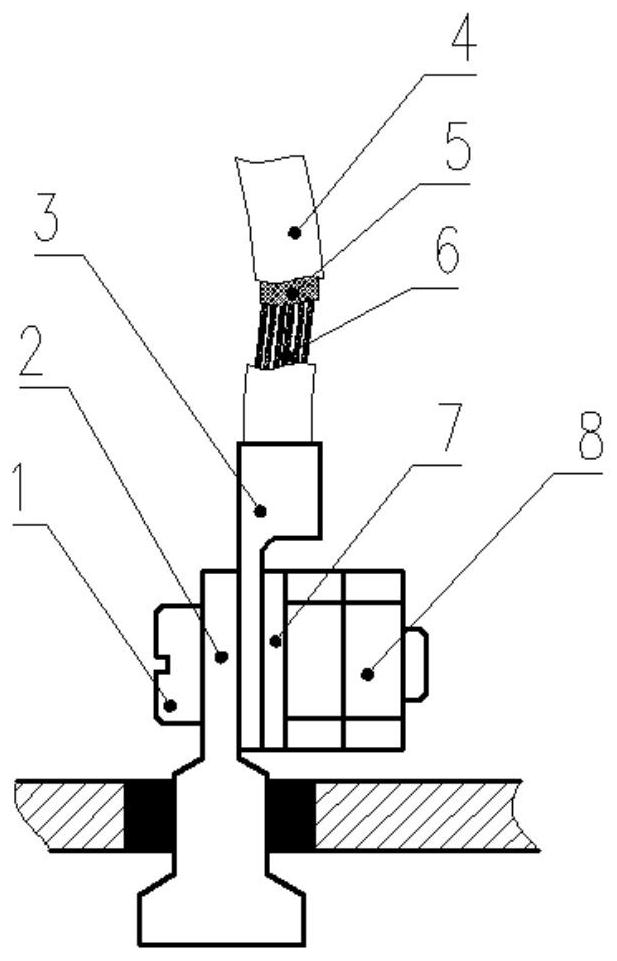

[0022] The following will combine Figure 1 ~ Figure 4 The cable connection structure of the thermal battery used in the environment of 450°C of the present invention will be further described in detail.

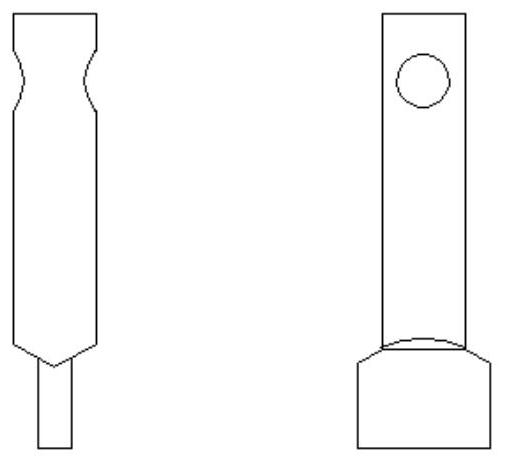

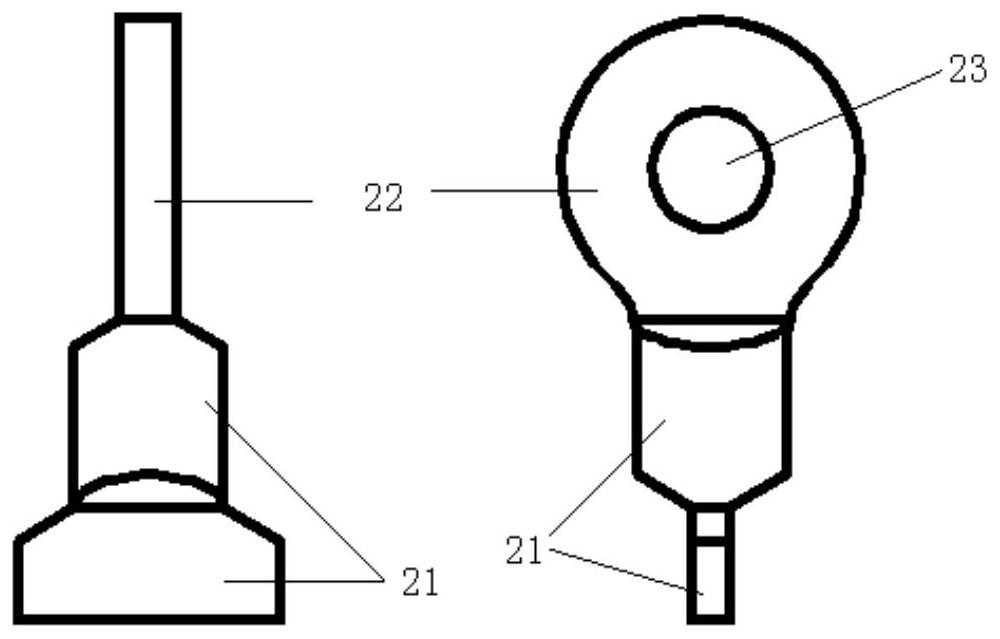

[0023] figure 2 Shown is a schematic diagram of the heat battery cable connection structure in a preferred implementation of the present invention; image 3 Shown is a schematic diagram of the electric energy output terminal of the thermal battery in a preferred implementation of the present invention.

[0024] see figure 2 , the thermal battery cable connection structure used in the 450°C environment of this embodiment includes screws 1, power output terminals 2, crimp terminals 3, high temperature resistant cables and nuts 8;

[0025] The screw 1 is inserted through the through hole on the electric energy output terminal 2;

[0026] The crimping terminal 3 is sleeved on the screw 1 and fastened by the nut 8, and is closely attached to the electric energy output termi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com