Catalyst grading method for catalytic oxidation of sulfur-containing VOCs, and method for catalytic oxidation of sulfur-containing VOCs

A catalytic oxidation and catalyst technology, applied in the field of VOCs treatment, can solve the problems of low efficiency, single layout, high investment cost, and achieve the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

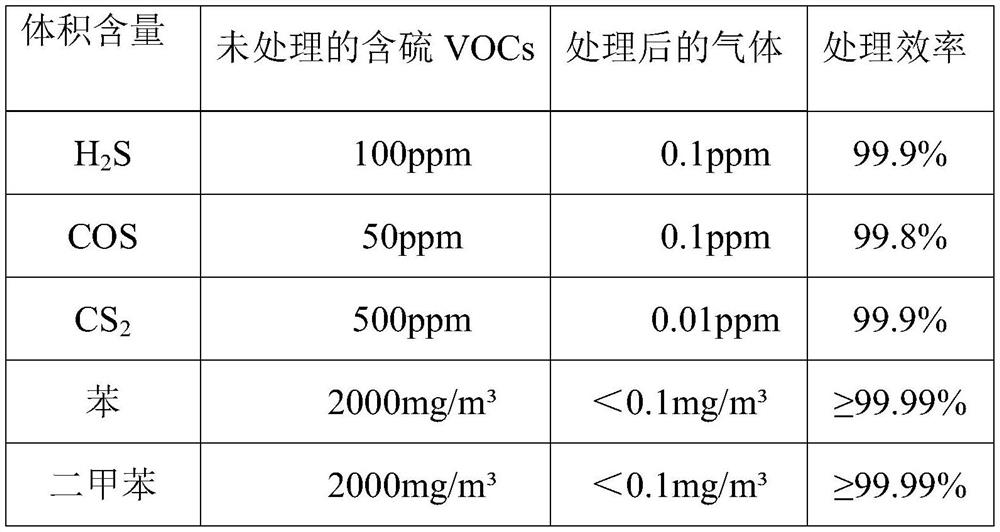

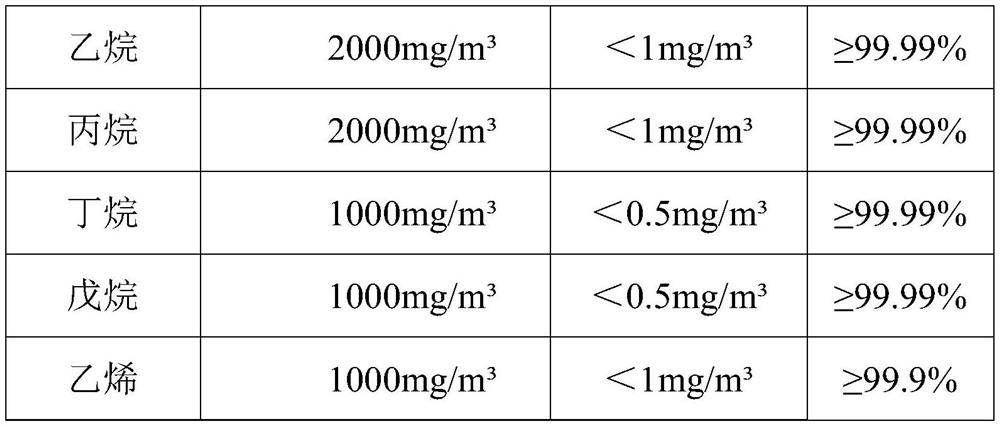

Examples

Embodiment 1

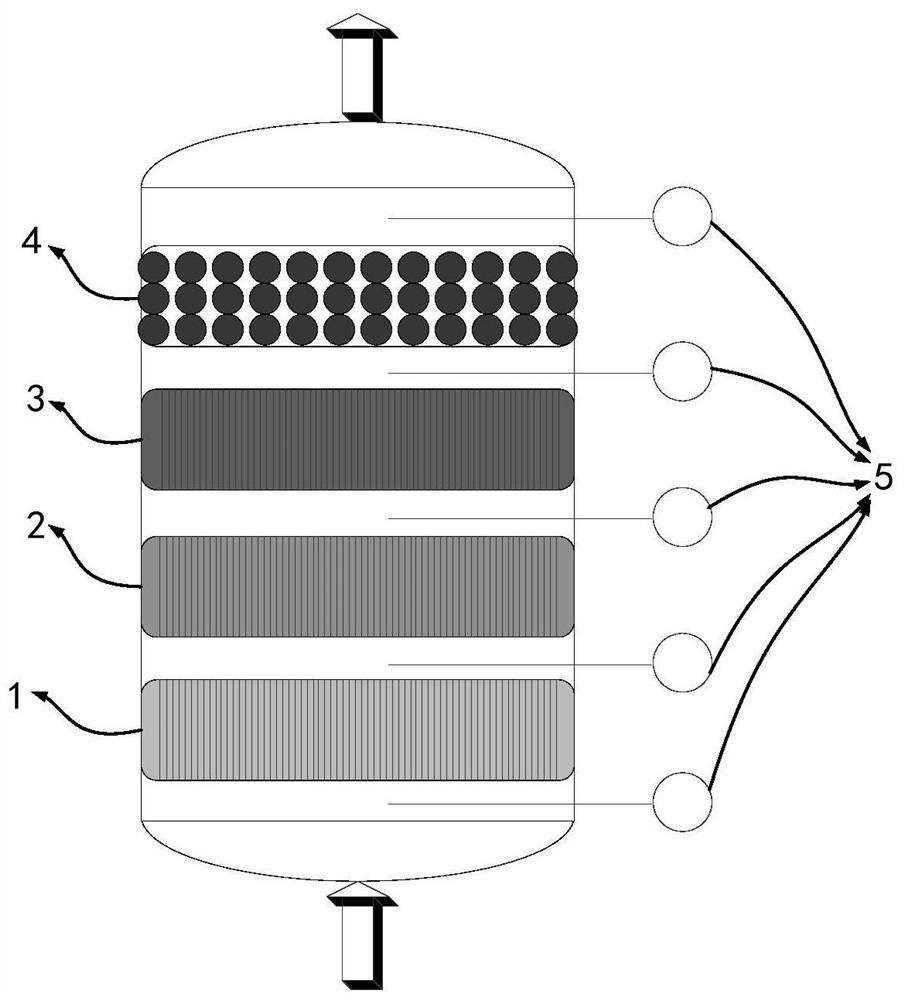

[0073] The mixed reaction gas obtained by mixing sulfur-containing VOCs with oxygen-containing gas passes through five catalyst beds in series, and under the conditions of catalytic oxidation reaction, it is contacted with the catalyst. According to the order of contact with the mixed reaction gas, the five The catalyst beds in series are the desulfurization bed, the first catalyst bed, the second catalyst bed, the third catalyst bed and the fourth catalyst bed;

[0074] Wherein, the desulfurizer filled in the desulfurization bed is a honeycomb desulfurizer (Cpsi value is 300) with ZnO as the main active component, and the contact reaction conditions carried out in the bed are that the space velocity of the reaction is 3000h -1 , the reaction temperature is 310°C;

[0075] The first catalyst filled in the first catalyst bed is granular Co 2 o 3 Catalyst, the contact reaction condition that carries out in this bed layer is, the space velocity of reaction is 6000h -1 , the re...

Embodiment 2

[0086] The mixed reaction gas obtained after mixing sulfur-containing VOCs with oxygen-containing gas (the volume fraction of oxygen is 2%) passes through four catalyst beds in series, and under the conditions of catalytic oxidation reaction, the contact reaction with the catalyst is carried out. According to the mixed reaction The contact sequence of the reactor, the four catalyst beds in series are the desulfurization bed, the first catalyst bed, the second catalyst bed and the third catalyst bed;

[0087] Wherein, the desulfurizer filled in the desulfurization bed is a honeycomb desulfurizer (Cpsi value is 300) with ZnO as the main active component, and the contact reaction conditions carried out in the bed are that the space velocity of the reaction is 3000h -1 , the reaction temperature is 310°C;

[0088] The first catalyst filled in the first catalyst bed is a honeycomb ceramic catalyst (Cpsi value is 300) with Pt as the main active component, and the contact reaction co...

Embodiment 3

[0096] The mixed reaction gas obtained by mixing sulfur-containing VOCs with oxygen-containing gas passes through four catalyst beds in series, and under the conditions of catalytic oxidation reaction, it is contacted with the catalyst. According to the order of contact with the mixed reactor, the four The catalyst beds in series are successively the first catalyst bed, the second catalyst bed, the third catalyst bed, and the fourth catalyst bed;

[0097] Wherein, the desulfurizer filled in the desulfurization bed is a honeycomb desulfurizer (Cpsi value is 300) with ZnO as the main active component, and the contact reaction conditions carried out in the bed are that the space velocity of the reaction is 2500h -1 , the reaction temperature is 350°C;

[0098] The first catalyst filled in the first catalyst bed is a honeycomb ceramic catalyst (Cpsi value is 400) with Co as the main active component, and the contact reaction conditions carried out in this bed are that the space ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com