Production method of surface layer compressed enhanced super-stable solid wood floor heating floor board

A production method and floor heating technology, which is applied in the field of surface compression and enhanced ultra-stable solid wood floor heating floor board production, to achieve the effect of reducing processing procedures and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

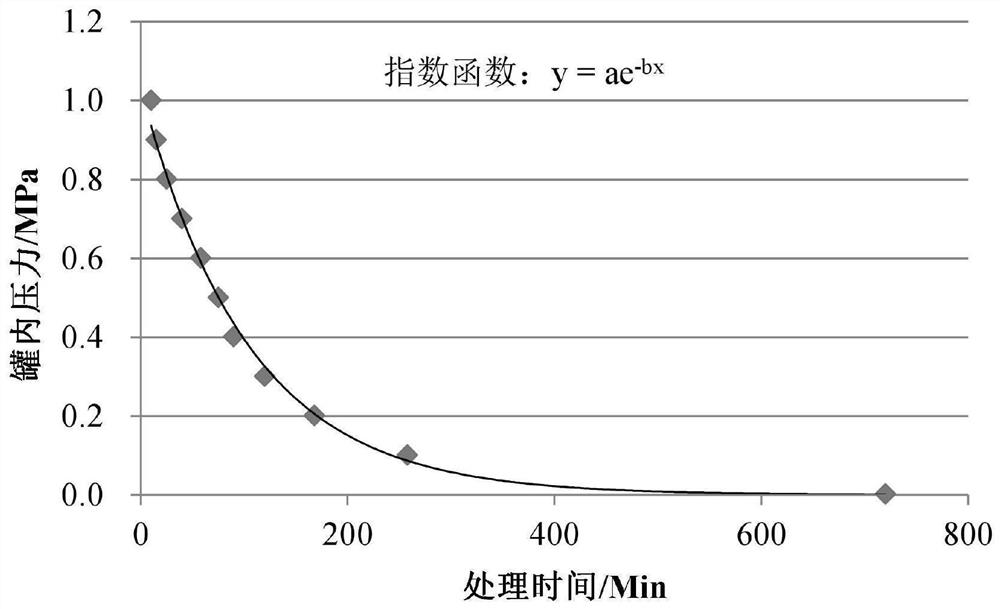

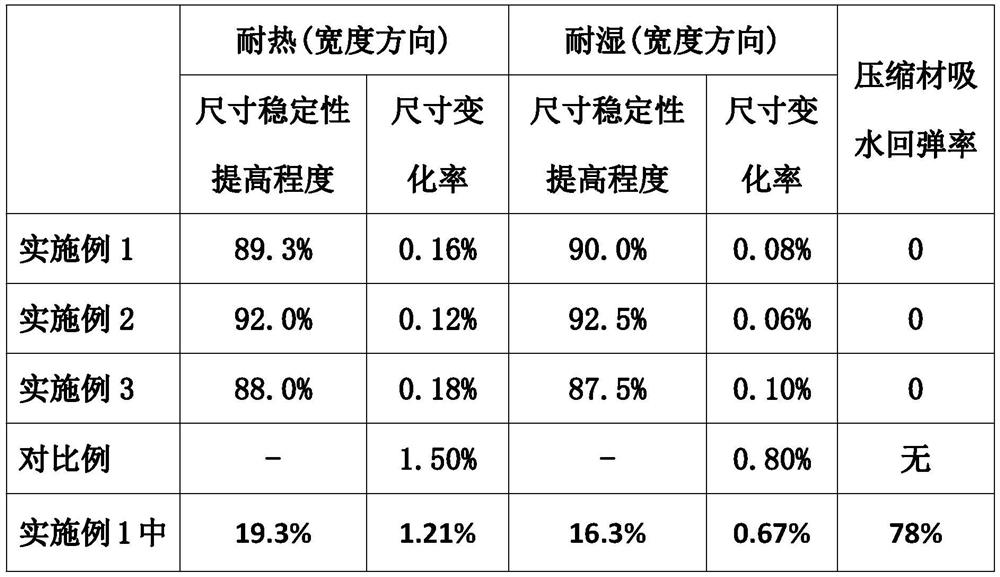

[0021] Embodiment 1: The production method of surface layer compression enhanced ultra-stable solid wood floor heating floor board, choose density 0.4g / cm 3 The floor board or base material has a moisture content of less than 15%; the thickness is selected to be 30mm, the surface of the floor board or base material is flat, and the total amount of water added to the surface of the floor board or base material by spraying, dipping or immersing in water reaches 0.1g / cm 2 Then put it into the hot pressing plate at 150°C, close the hot pressing plate quickly in no more than 1 minute, the pressure in the closed state is less than 1MPa, then heat it at 150°C for 50 seconds, and then press the Compress wood to a predetermined thickness of 20mm, surface density 0.85g / cm 3 , and then keep it for 5 minutes, reduce the pressure of the hot press plate to 1MPa, and take out the wood after the temperature drops below 60°C to complete a stabilization treatment.

[0022] Palletize the compr...

Embodiment 2

[0025] Embodiment 2: the production method of surface layer compression enhanced ultra-stable solid wood floor heating floor board, choose density 0.4g / cm 3The floor board or base material has a moisture content of 10%; the thickness is selected at 30mm, the surface of the floor board or base material is flat, and the total amount of water added to the surface of the floor board or base material by spraying, dipping or immersing in water reaches 0.03g / cm 2 Then put it into a hot press plate at 160°C, close the hot press plate quickly in no more than 1 minute, the pressure in the closed state is less than 1MPa, and then heat it at 160°C for 40 seconds, and then press it with a pressure of 5MPa Compress wood to a predetermined thickness of 20mm, surface density 0.95g / cm 3 , and then keep it for 5 minutes, reduce the pressure of the hot press plate to 1MPa, and take out the wood after the temperature drops below 60°C to complete a stabilization treatment.

[0026] Palletize the...

Embodiment 3

[0029] Embodiment 3: the production method of surface layer compression enhanced ultra-stable solid wood floor heating floor board, choose density 0.4g / cm 3 The floor board or base material has a moisture content of 10%; the thickness is selected at 30mm, the surface of the floor board or base material is flat, and the floor board or base material is sprayed with water, dipped in water or soaked in water to increase the amount of water on the surface to 0.05g / cm 2 Then put it into a hot press plate at 145°C, close the hot press plate quickly in no more than 1 minute, the pressure in the closed state is less than 1MPa, and then heat it at 145°C for 40 seconds, and then press it with a pressure of 5MPa Compress wood to a predetermined thickness of 20mm, surface density 0.90g / cm 3 , and then keep it for 4 minutes, reduce the pressure of the hot press plate to 1MPa, and take out the wood after the temperature drops below 60°C to complete a stabilization treatment.

[0030] Pall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com