Process and tool for preparing sodium metasilicate pentahydrate by utilizing crystallization and crushing method

A technology of sodium metasilicate pentahydrate and pulverization method, applied in silicate, alkali metal silicate and other directions, can solve the problems of low cost performance, blackening, and large amount of cooling water, so as to improve manufacturing efficiency and reduce Manufacturing cost and effect of improving ingredient ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

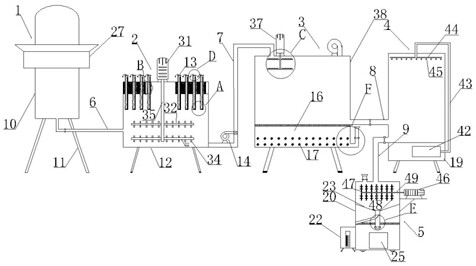

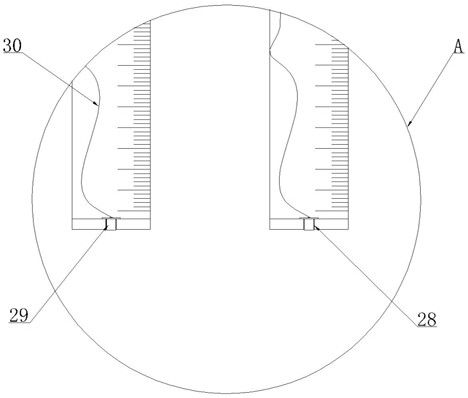

[0036] Such as Figure 1~7Shown, a kind of tooling that utilizes crystal pulverization to prepare sodium metasilicate pentahydrate, it comprises raw material storage system 1, batching system 2, vacuum concentration system 3, cooling crystallization system 4, milling system 5, packing weighing system and Control system, a feeding pipeline 1 is provided between the raw material storage system 1 and the batching system 2, a feeding pipeline 2 7 is provided between the batching system 2 and the vacuum concentration system 3, and the vacuum concentration system 3 and the cooling crystallization A feeding pipeline 3 8 is arranged between the systems 4, and a feeding pipeline 4 9 is arranged between the cooling crystallization system 4 and the pulverizing system 5, and the diameter of the feeding pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com