Control method of pyrolysis gasification system

A technology of pyrolysis gasification and control method, which is applied in the direction of gasification process, gasification device feeding tool, manufacture of combustible gas, etc., can solve the problem that the pressure of pyrolysis gasification system is not easy to control, and affects the quality of combustible gas and gas production Stability and other issues, to achieve the effect of easy pressure, improved stability, and simple control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

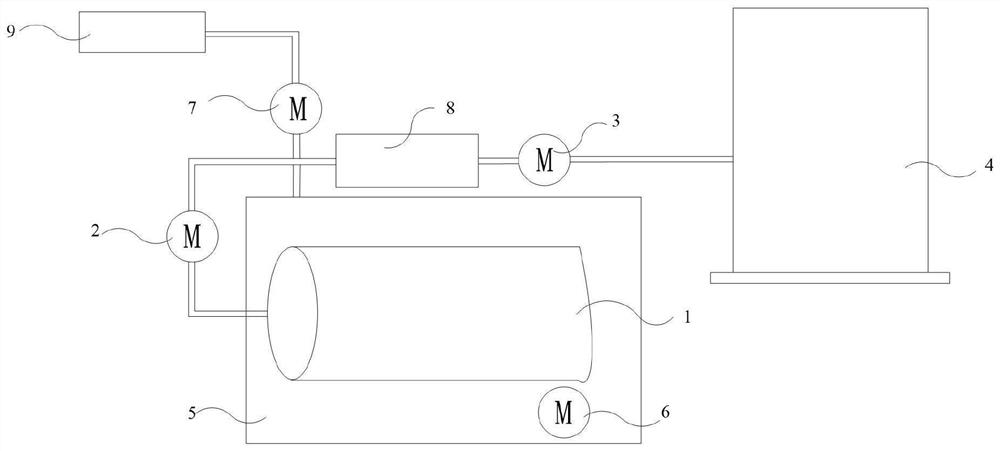

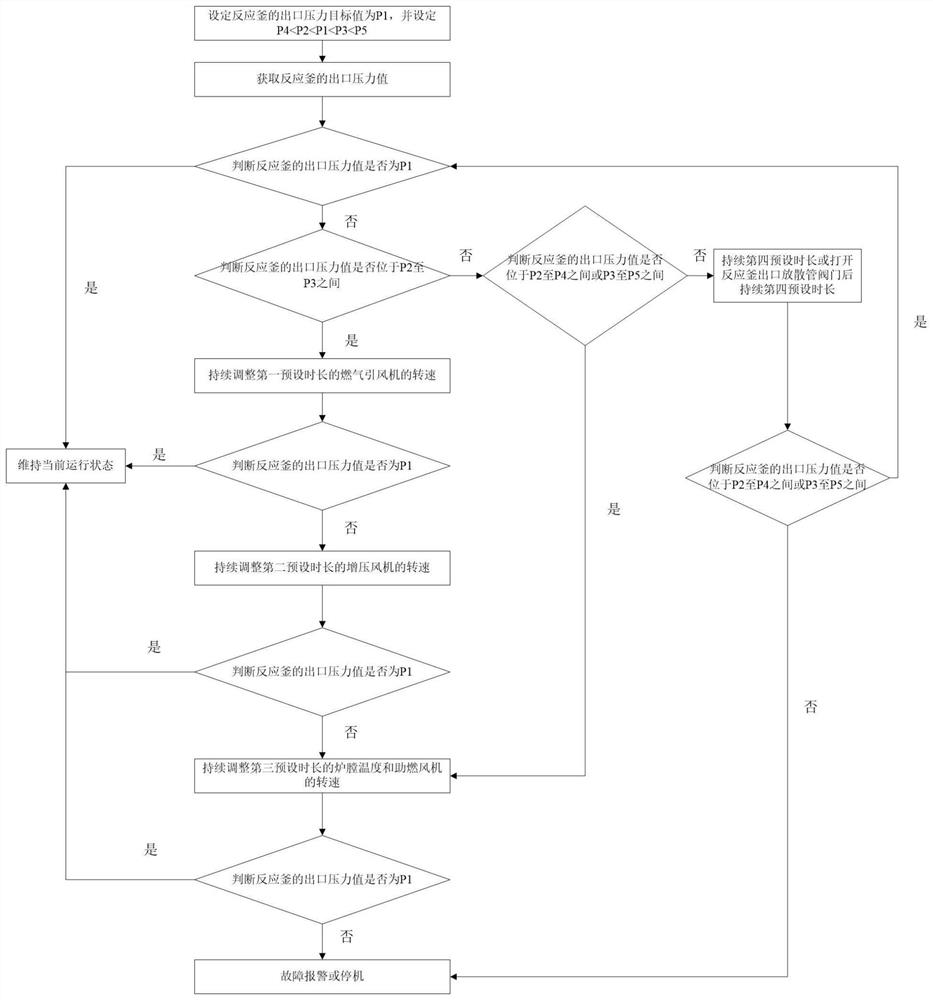

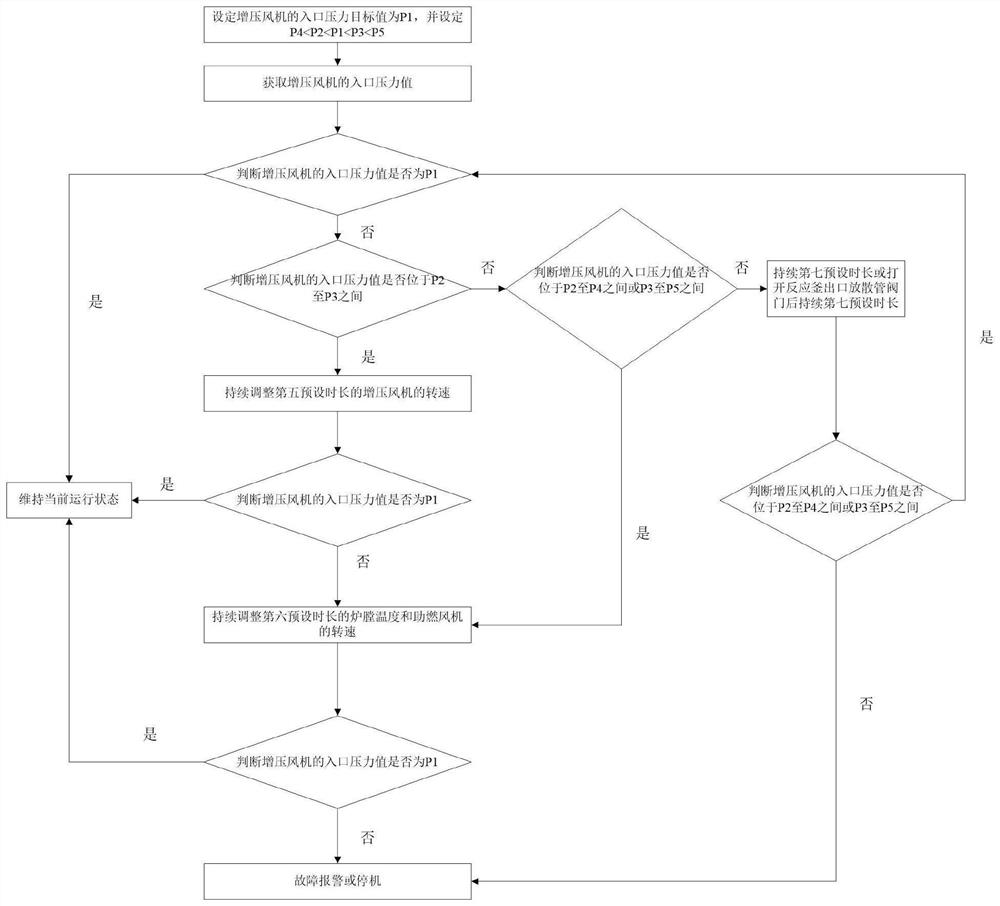

[0047] During the process of pyrolysis and gasification of biomass raw materials such as straw, the combustible gas generated from the reactor is transported to the gas storage device through the gas induced draft fan and the booster fan in turn, and the smoke generated by the furnace installed outside the reactor The gas is discharged after passing through the flue gas induced fan and the flue gas purification device. The outlet pressure of the reactor is affected by the gas induced fan, the booster fan and the gas production in the reactor, and the gas production in the reactor is related to the temperature of the furnace and the combustion fan. , the feed volume of the reactor, the discharge volume of the reactor, and whether the feed port forms a material seal. The outlet pressure control of the reactor is affected by various coupling factors. If only one of the factors is adjusted, the reaction The influence of the pressure at the outlet of the reactor may cause excessive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com