Catalyst for preparing combustible gas by wet biomass and application

A catalyst and biomass technology, applied in the field of supercritical water gasification of wet biomass to produce flammable gas, can solve the problems of few researches on supercritical water gasification of biomass, and achieve good mass and heat transfer properties , High energy utilization rate, easy to handle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

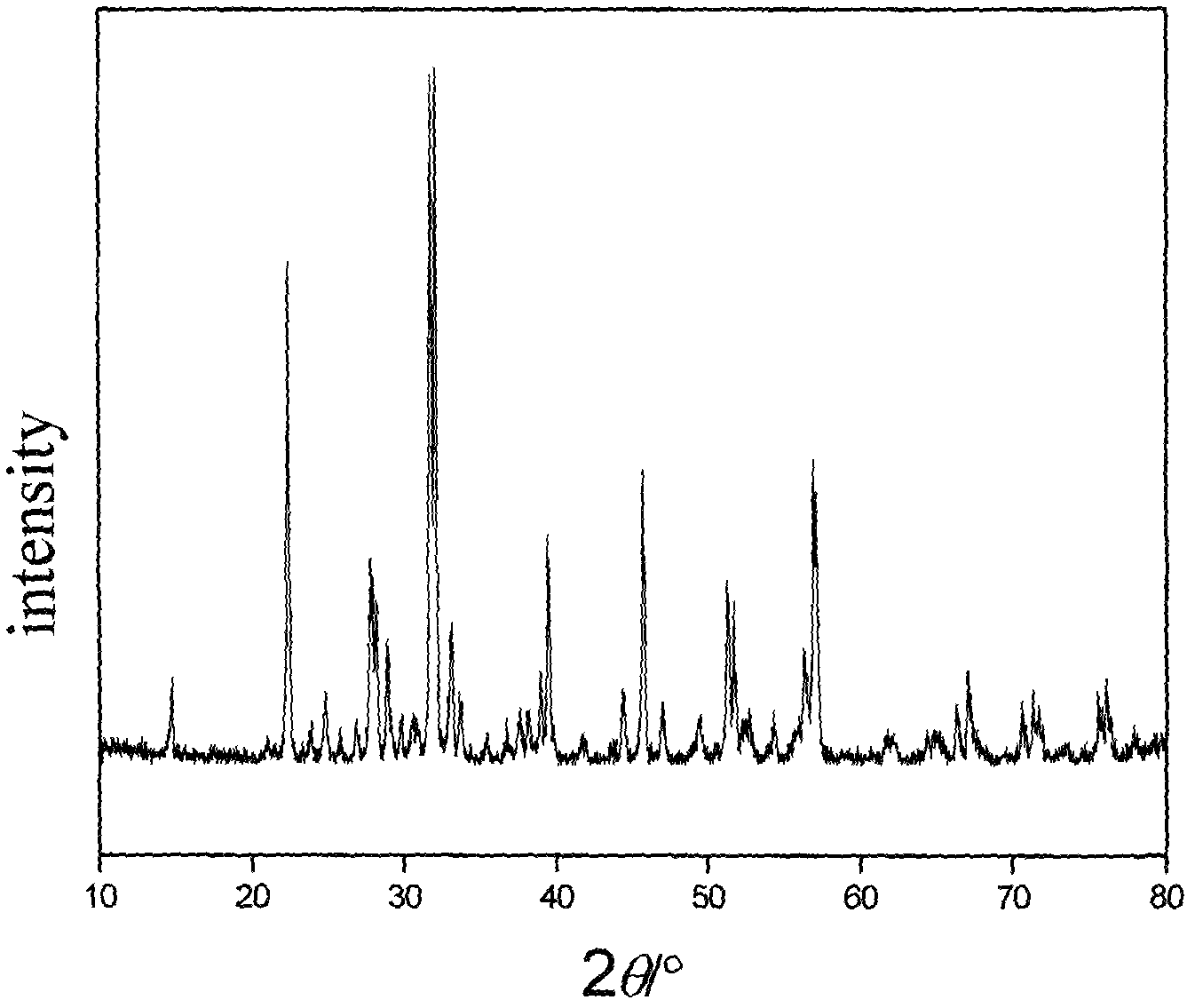

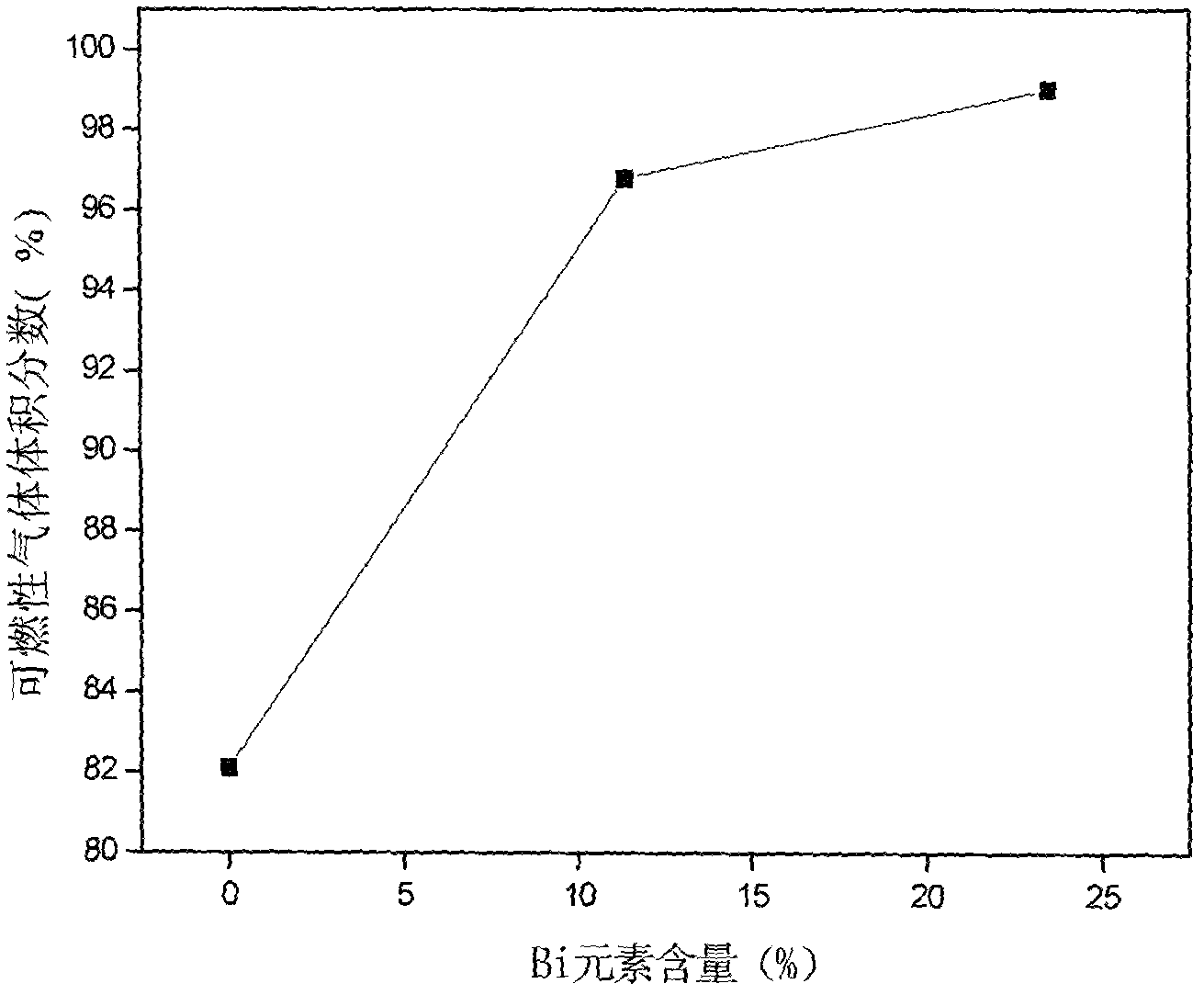

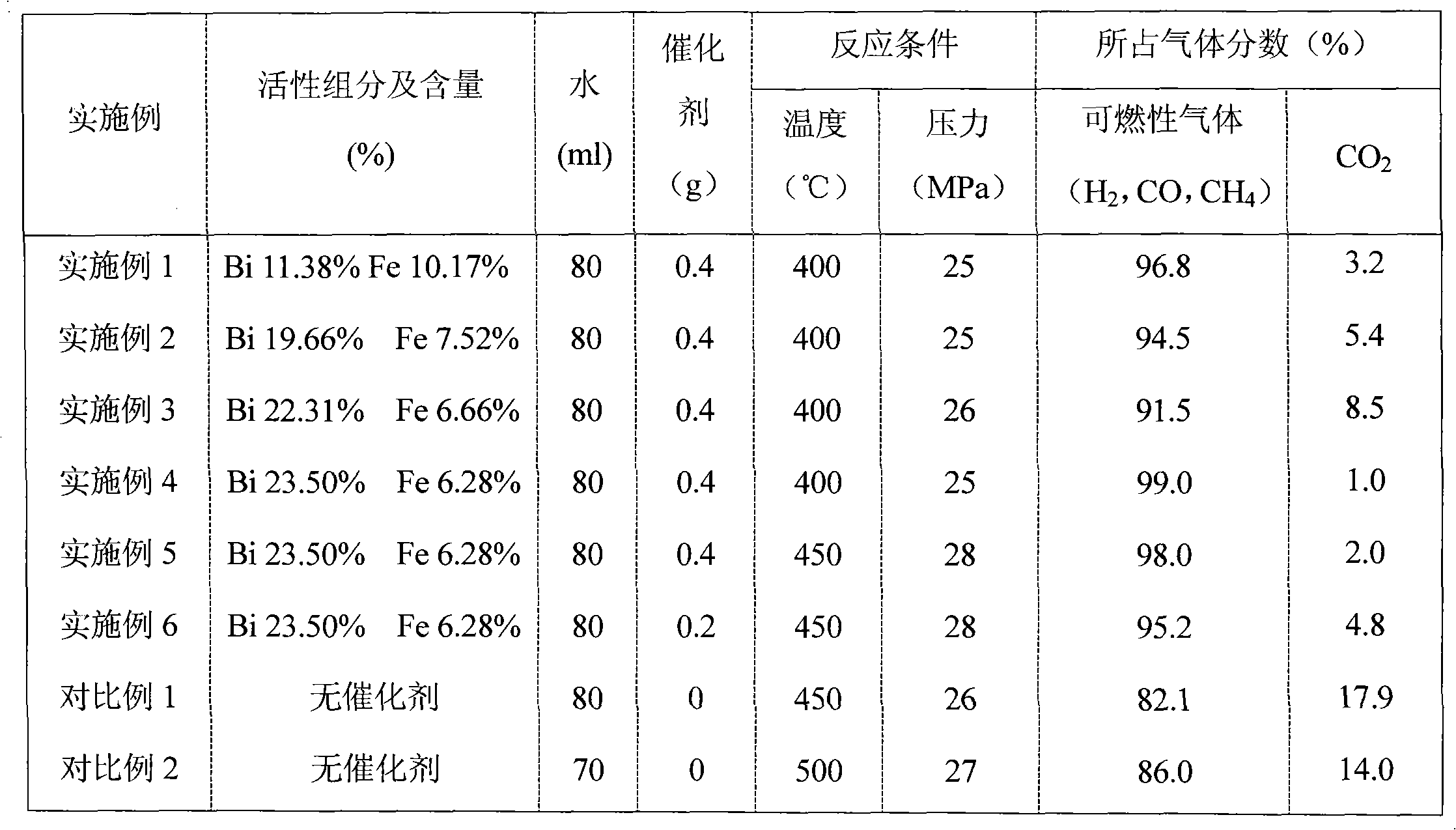

Embodiment 1

[0022] Embodiment 1: 4.85gBi (NO 3 ) 3 ·5H 2 O, 4.04gFe(NO 3 ) 3 9H 2 O made into solution, Bi(NO 3 ) 3 ·5H 2 O was dissolved with dilute hydrochloric acid, then citric acid with twice the molar amount of metal ions was added, and viscous sol was formed by vigorous stirring at 70°C, dried at 100°C to obtain a xerogel precursor, and calcined at 700°C. The catalyst activity of the prepared catalyst was measured according to the following method: 2 g of crushed and sieved corn stalk powder, 0.4 g of catalyst, and water were put into a self-made 200 ml supercritical reactor. The system was boosted to 20MPa with inert gas argon for leak detection, and the leak detection was completed. The temperature and pressure were gradually adjusted to the required level, and the reaction was timed after maintaining the stability. Afterwards, the reaction kettle was cooled to room temperature, and the gas products were collected for gas chromatography analysis. GC-14C gas chromatograph...

Embodiment 2

[0023] Embodiment 2: Catalyst raw material is 4.34gBi(NO 3 ) 3 ·5H 2 O, 4.04gFe(NO 3 ) 3 9H 2 O, its preparation process and the resulting catalyst used in the supercritical biomass water gasification reaction process are the same as in Example 1.

Embodiment 3

[0024] Embodiment 3: Catalyst raw material is 3.39gBi (NO 3 ) 3 ·5H 2 O, 4.04gFe(NO 3 ) 3 9H 2 O, its preparation process and the resulting catalyst used in the supercritical biomass water gasification reaction process are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com