Smelting method for reducing explosion venting occurrence rate of converter

A smelting method and a technology of occurrence rate, which are applied in the smelting field to reduce the incidence of explosion venting of converters, can solve the problems of lower production efficiency, interruption of converter production, and high incidence of explosion venting, and achieve low production costs, lower incidence of explosion venting, highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

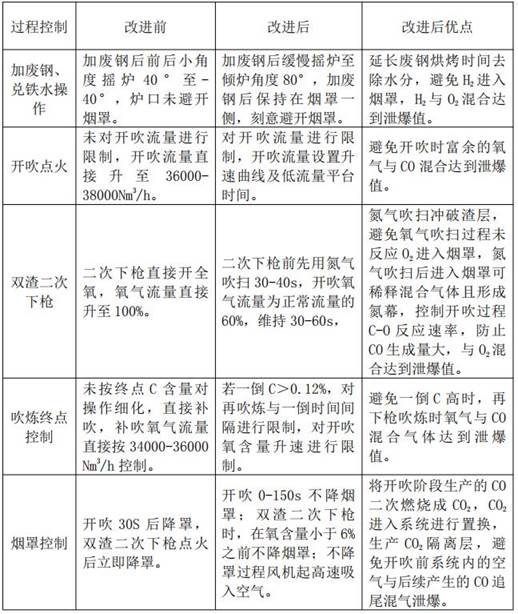

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, the single slag smelting method is taken as an example to describe the method of the present invention in detail.

[0031] The smelting furnace No. 1 is smelted by the single slag method, and the blowing end point is ≤0.12%. The specific operation includes the following steps:

[0032] (1) Control of adding steel scrap and adding iron

[0033] ①Adding scrap steel operation: After adding scrap steel, in order to effectively bake the scrap steel, remove the moisture in the scrap steel (to avoid the generation of H 2 ), after adding scrap steel, slowly shake the furnace until the tilting angle is 80°, and attention should be paid to avoiding the fume hood at the furnace mouth to prevent H 2 Enter the fume hood, and then slowly shake the furnace to the waiting position to add iron;

[0034] ②Molten iron mixing operation: After mixing the molten iron, do not shake the furnace body immediately, first slowly shake the furnace body at a small angle (the sh...

Embodiment 2

[0045] This embodiment takes double slag smelting as an example to describe the method of the present invention in detail.

[0046] The smelting furnace No. 2 is smelted by the double slag method, and the blowing end point of the blowing furnace is C>0.12%. The specific operation includes the following steps:

[0047] (1) Control of adding steel scrap and adding iron

[0048] ①Adding scrap steel operation: After adding scrap steel, in order to effectively bake the scrap steel, remove the moisture in the scrap steel (to avoid the generation of H 2 ), after adding scrap steel, shake the furnace slowly until the tilting angle is 85°, and attention should be paid to avoiding the fume hood at the furnace mouth to prevent H 2 Enter the fume hood, and then slowly shake the furnace to the waiting position to add iron;

[0049] ②Molten iron mixing operation: After mixing the molten iron, do not shake the furnace body immediately, first slowly shake the furnace body at a small angle (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com