A permanent repair method for tunnel lining cracks using uhpc material

A repair method and lining technology, which is applied in the field of permanent repair of tunnel lining cracks, can solve problems such as complex construction, increased structural rigidity, self-heavyness, etc., and achieve enhanced repair effects, good repairability, and enhanced tensile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

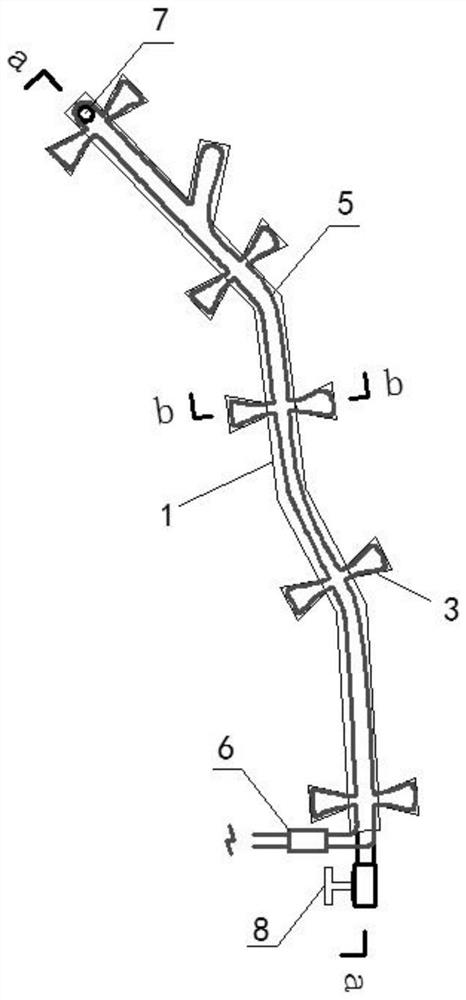

[0037] The invention discloses a method for permanently repairing tunnel lining cracks using UHPC materials. The permanent repair method is as follows:

[0038] Step S1, slotting construction on the crack A of the tunnel lining, the details are as follows:

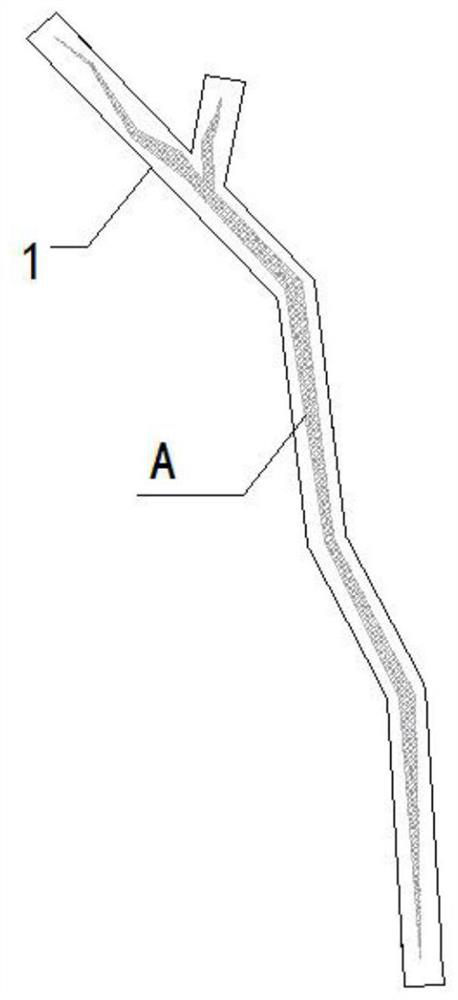

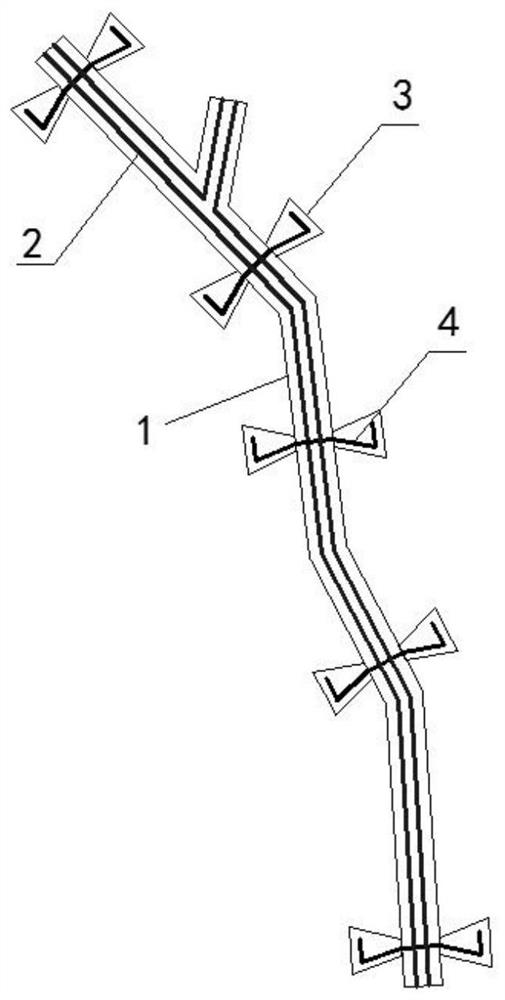

[0039] Step S11, cutting the left and right walls and bottom of the crack A in the tunnel lining to obtain a repaired main groove 1 with a rectangular cross section; the repaired main groove 1 is used to fill the UHPC material filler 10; the formed repaired main groove 1 is about 3 cm wide and deep About 5cm, repairing the size design of the main groove 1, after filling the UHPC material to form the UHPC material filling body 10, it meets the repairing requirements, such as figure 1 shown.

[0040] When the tunnel lining cracks, the depth of the tunnel lining crack A is much greater than 5cm, and the width of the cracks varies. If the width of the original tunnel lining crack a exceeds 3cm, there is no need for slotting c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com