Sea grass bottom laying planting method

A planting method and a bottom-laying technology, which are applied in the fields of seed treatment, botany equipment and methods, and plant cultivation, can solve the problems of heavy diving workload, lagging repair technology research, and large consumption of manpower and material resources, so as to reduce manpower The effect of material resource consumption, ensuring the restoration of the ecological environment, and requiring low operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Seagrass bottom shop planting method, comprises the steps:

[0042] 1) Collect seaweed seeds:

[0043] Collect seaweed seeds in the seagrass field in the seaweed fruiting period in advance, and reserve them;

[0044] 2) Seaweed seed pretreatment:

[0045] Select mature and plump seeds, first soak them in 60% alcohol solution for 30 seconds, rinse them with sterile seawater for 3 times, and set aside;

[0046] 3) Make the bottom layer of seeds:

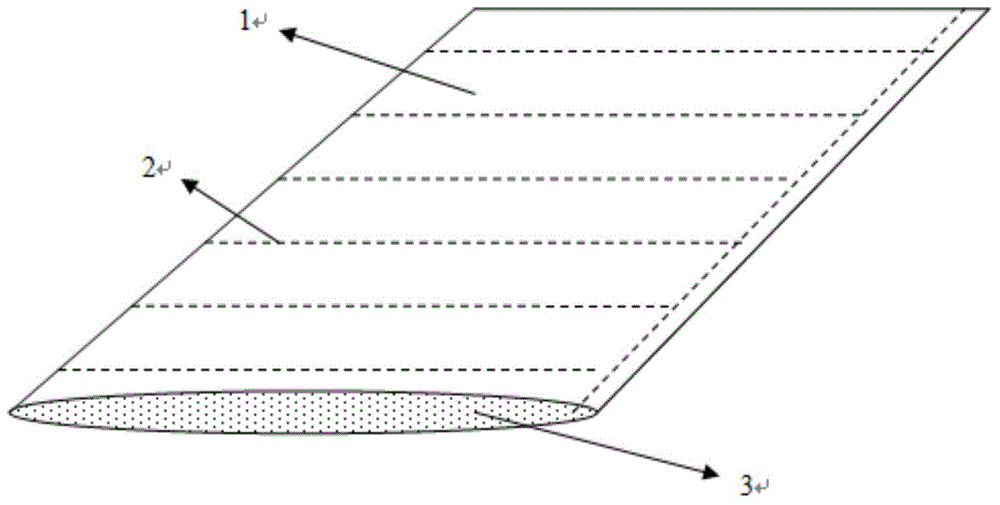

[0047] Fold the cotton fiber mesh cloth in half and sew it to make the bottom layer network frame 1;

[0048] Select ceramsite as the base material, mix the base material and the pretreated seeds evenly to obtain the filler 3, fill the filler 3 in the bottom layer network frame 1, and then wrap the bottom layer network frame 1 with jute thread Sew the seam to obtain the bottom layer of seeds;

[0049] 2,000 seeds per square meter of seed bottom layer;

[0050] 4) Conveying and delivery of the bottom layer:

[0051] Put th...

Embodiment 2

[0053] Seagrass bottom shop planting method, comprises the steps:

[0054] 1) Collect seaweed seeds:

[0055] Cut off the reproductive branches with mature seeds in the seagrass field in the seaweed fruiting period in advance, and transport them to the pool of the nursery room for temporary cultivation in an incubator treated with ice. Change the water once a day. After the seeds fall off naturally, put The scattered seeds are collected in another pond for subsequent use;

[0056] 2) Seaweed seed pretreatment:

[0057] Select the seeds whose epidermis is transparent and can see the small germ buds inside the seeds as mature and plump seeds through microscopic observation, soak them in 90% alcohol solution for 30 seconds, wash them with sterile sea water for 3 times, and set them aside;

[0058] 3) Make the bottom layer of seeds:

[0059] Fold the jute mesh cloth in half and sew it according to the following steps to make the bottom layer network frame 1: a) fold the jute me...

Embodiment 3

[0065] In the step of the seaweed bottom shop planting method, except that the following content is different from Example 2, all the other contents are the same: in step 2), the alcohol solution is an alcohol solution with a volume fraction of 75%; in step 3), the substrate is pottery The mixture of granules, sea sand and the bottom mud of the former seagrass field, wherein the weight and number ratio of ceramsite, sea sand and the bottom mud of the former sea grass field is 3:1:1; in step 3), the plant fiber mesh used is No. 40 jute mesh cloth, the used plant fiber suture is jute thread; in step 3), contain 2500 seeds in the bottom layer of every square meter of seeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com