Construction method of soft surrounding rock tunnel collapse cave foam concrete backfill structure

A technology of foam concrete and construction method, which is applied in the direction of infrastructure engineering, tunnels, tunnel linings, etc., and can solve problems such as the deformation mechanism of tunnel surrounding rocks, insufficient understanding of development and evolution laws, lack of pertinence in control technologies and methods, and constraints on project schedules, etc. , to achieve the effect of improving anchorage strength, increasing strength and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

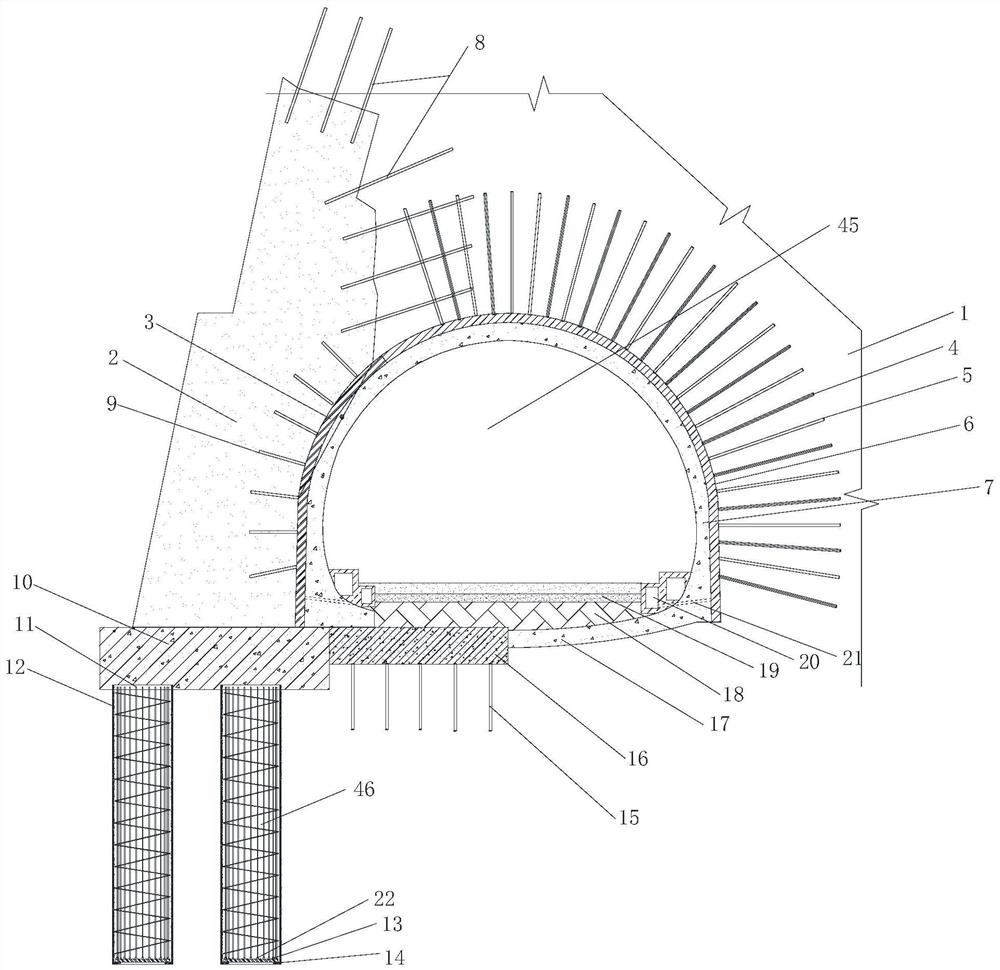

[0048] The soft surrounding rock tunnel collapsed cavity foam concrete backfill structure, manual excavation piles are constructed with assembled casings, reinforced concrete support walls are set on the side of the weak surrounding rock, the caves on the side of the cave are backfilled with prefabricated slabs closed foam concrete, and the vault is small and water-free The karst caves are backfilled with prefabricated slabs closed with anchor rods, and the small karst caves at the bottom are backfilled with prefabricated beams and slabs closed with foamed concrete. Such as Figure 1-2 As shown, its structure includes weak surrounding rock 1, support wall 2, pre-embedded steel frame 3, shotcrete 6, pile cap 10, steel cage 11, assembled casing 12, steel cage shaped tire frame 13, top Sealing plate 31, foam concrete 33, prefabricated slab 34, hanging anchor rod 38, tunnel 45, artificial hole-digging pile 46, etc., the bottom of pile foundation cap 10 is provided with artificial ...

Embodiment 2

[0054] The present invention also provides a construction method of a foam concrete backfill structure for a collapsed hole in a weak surrounding rock tunnel, comprising the following steps:

[0055] (1) Construction and production: prefabricated casing 12, steel cage shaped tire frame 13, top sealing plate 31, arch side prefabricated plate 43, prefabricated roof plate 39, etc., are shipped to the construction site for assembly.

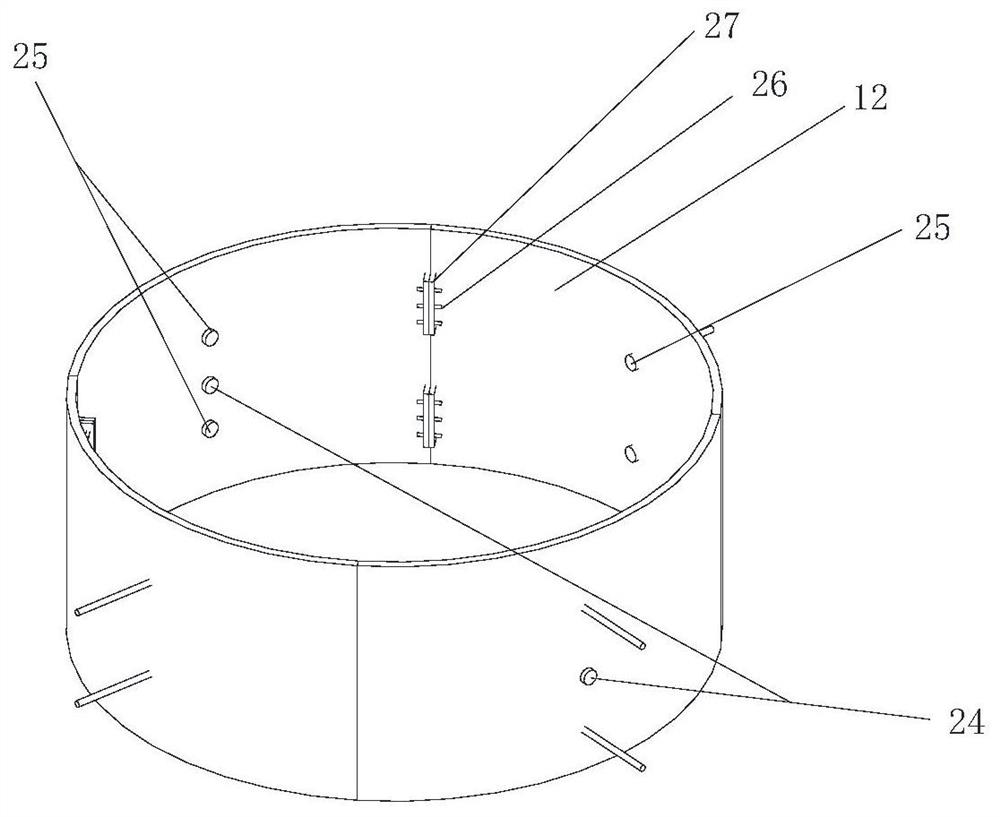

[0056] (2) Excavation of manual hole-digging piles: install the assembled casing 12 after excavating to a certain depth, each arc-shaped plate of the assembled casing 12 is spliced by ear plate bolts 26, and each arc-shaped plate is fixed by fixing the anchor rod Be fixed in the pile hole, and open or close the drain valve 24 on the arc-shaped plate according to the water flow in the hole.

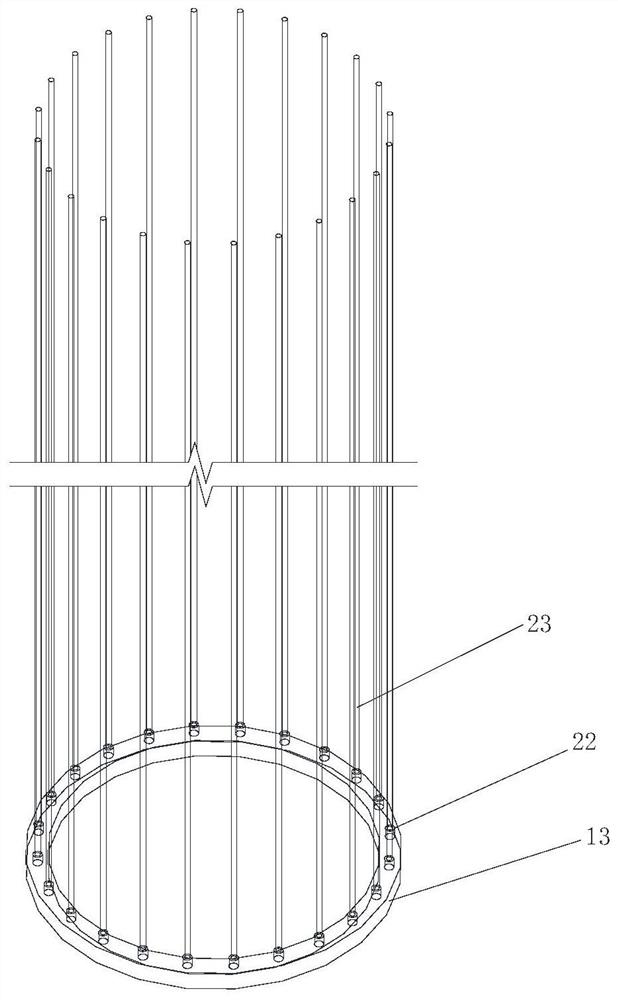

[0057] (3) Reinforcement cage tying: After installing pads 14 at the bottom of the artificially dug pile 46 pile holes, install the reinforced cage stereotyped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com