Closed rotary type annular turbojet steam wheel

A steam wheel and rotary technology, applied in stators, engine components, machines/engines, etc., can solve problems affecting service life, parts corrosion, steam waste, etc., and achieve the effects of prolonging service life, avoiding corrosion, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, the embodiment in which the intermediate shaft is the power take-off shaft

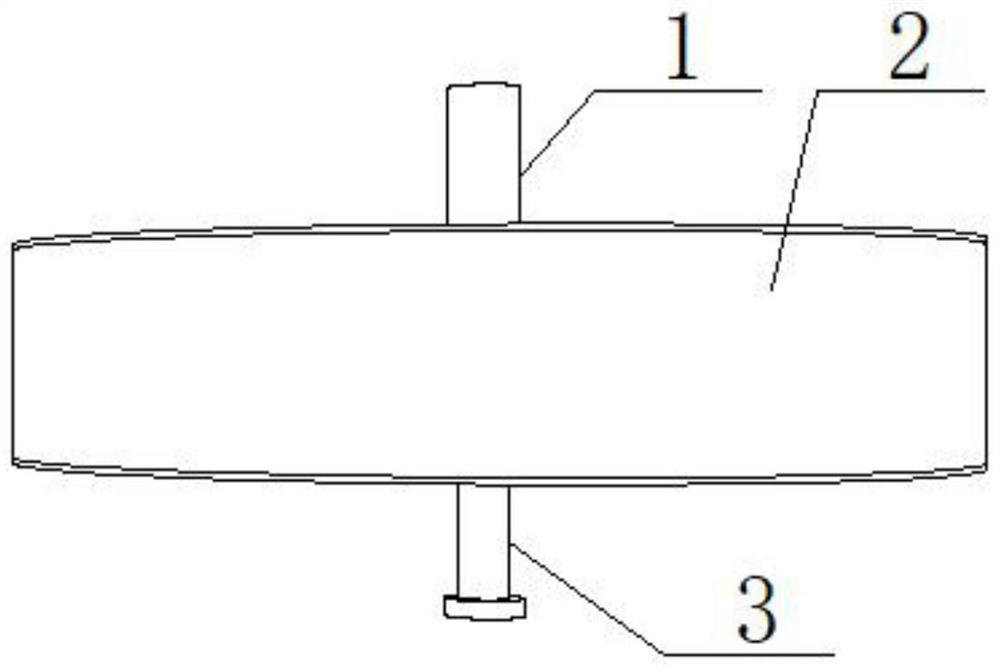

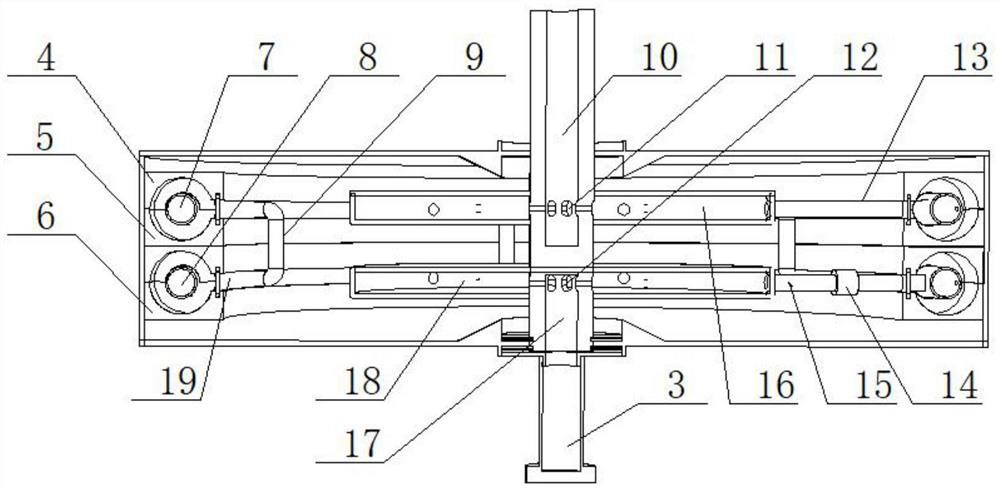

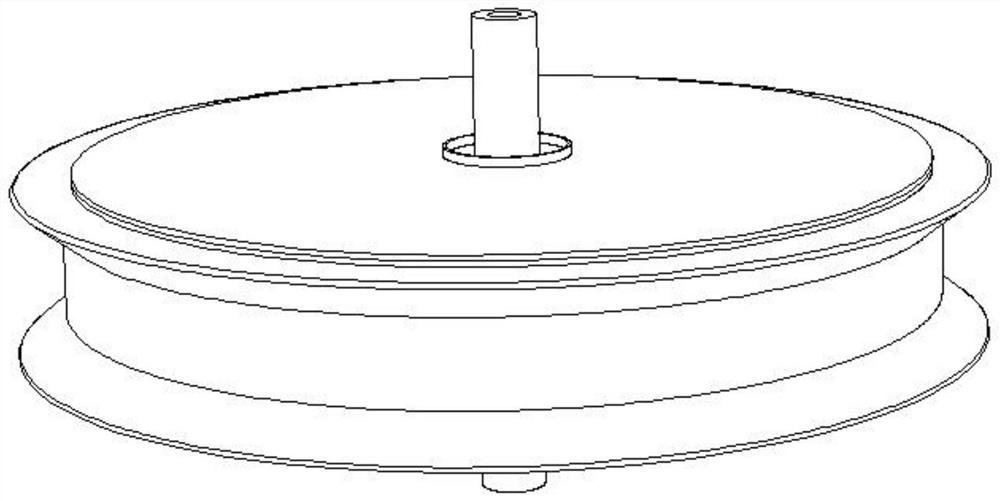

[0045] attached by Figure 1-2 as shown,

[0046] The sealed injection chamber is a one-stage and two-stage sealed injection chamber structure. For the convenience of assembly, the lower vortex of the upper single-stage sealed injection chamber and the upper vortex of the lower single-stage sealed injection chamber can be designed as an integrated structure. form the middle vortex,

[0047] Specifically, the structure of the two-stage sealed injection chamber includes an upper vortex 4, a middle vortex 5, and a lower vortex 6 fixedly mounted on the inner wall of the casing, and the middle vortex and the lower vortex are fastened together to form a primary injection space. , the upper vortex and the middle vortex are fastened to form a secondary injection space, and a primary injection ring 8 and a secondary injection ring 7 are respectively installed in the primary injection spa...

Embodiment 2

[0054] Embodiment 2, the embodiment in which the casing is a power output

[0055] The difference between this embodiment 2 and embodiment 1 is that the intermediate shaft of this embodiment 2 is a fixed embodiment, and compared with embodiment 1, the structure is simpler and the torque is also larger.

[0056] The intermediate shaft in this embodiment is a structure in which the upper and lower ends pass through the upper and lower ends of the housing respectively, and the housing rotates around the intermediate shaft through bearings.

[0057] When in use, the power source (steam) is directly connected to the intake air passage at the bottom of the intermediate shaft, the steam enters the exhaust collector, and the steam in the exhaust collector enters the first-stage injection ring from the intake branch pipe, and the first-stage injection The ring injects steam to the resistance sheet of the sealed injection chamber, and uses the injection force to push the sealed injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com