Online mixed stacking method based on buffer area

A buffer zone and mixed code technology, applied in the field of cargo palletizing, can solve the problems that the order and size of the cargo cannot be fully known in advance, increase the time of palletizing, and the type of cargo is not unique, etc., to solve the problem of single-standard palletizing, shorten Palletizing times, solving the effect of low space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

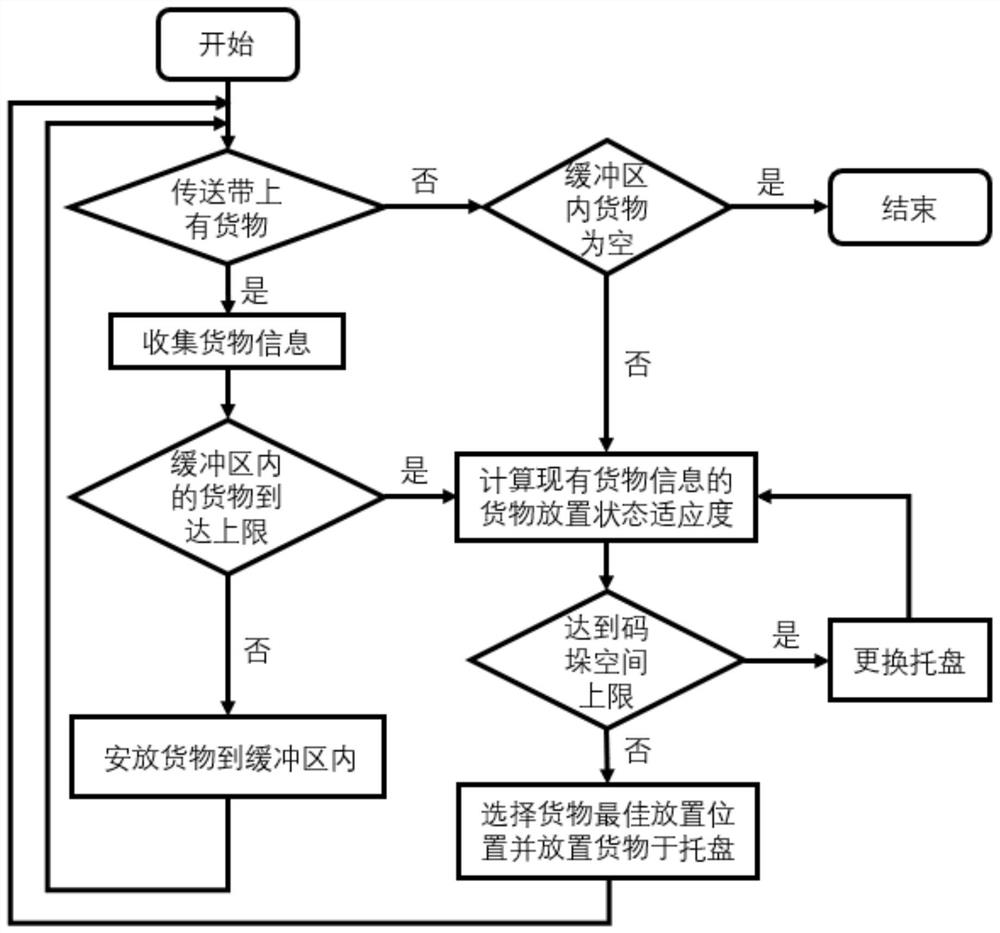

[0042] Such as figure 1 As shown, a buffer-based online mixed palletizing method includes the following steps:

[0043] Step A, place the goods on the conveyor belt into the buffer zone in sequence, collect the size information of the goods, and generate the placement posture of the goods;

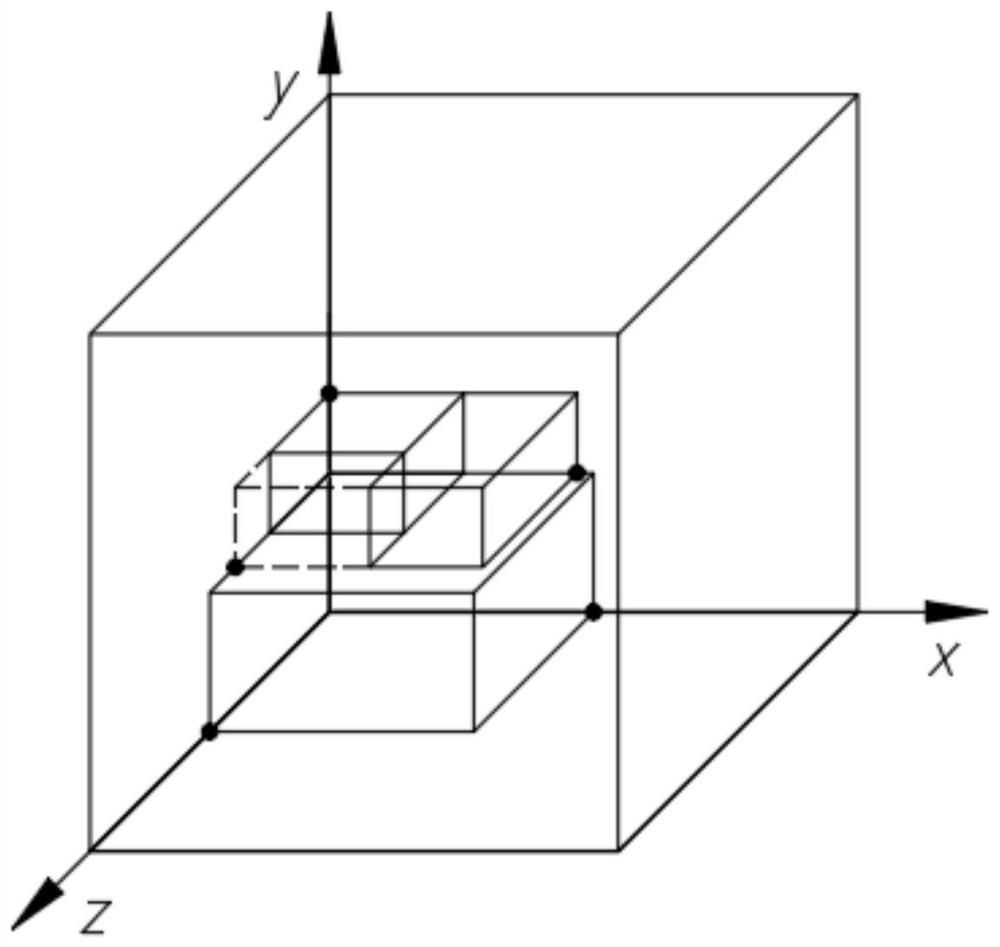

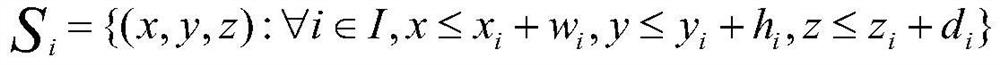

[0044] Step B, according to the space occupied by the placement posture of the goods, calculate the wasted space generated by the placement posture of a single goods and the placement order of multiple goods under different stacking methods when the goods are stacked onto the pallet. The above-mentioned wasted space is the gap between goods and goods, between goods and pallets;

[0045] Step C, select the palletizing scheme with the least wasted space and select the goods one by one from the buffer zone accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com