Formula and application of double-ion battery positive electrode

A battery positive electrode and dual-ion technology, which is applied to battery electrodes, non-aqueous electrolyte batteries, circuits, etc., can solve problems such as broken tape adhesion, pole piece curling, and low capacity, so as to improve adhesion and solve volume problems. edge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Dual-ion battery positive electrode formula: 92% active material (graphite), 1% carbon nanotube conductive agent (including solid carbon nanotube CNT, ACNT), 2.5% conductive carbon (Super-P), 1.0% binder (LA133) , 1% binder (LA136D), 1% softener (EC and PC) and 1.5% softener (NMP).

[0039] When preparing the slurry, an additional 0.5% of a dispersant is added, and the dispersant may specifically be a water-based conductive carbon black dispersant.

[0040] A method for preparing a positive electrode of a dual-ion battery, comprising the steps of:

[0041] S1, the slurry was prepared from the dual-ion battery cathode formulation and deionized water.

[0042] Specifically, pre-mix deionized water and binders (LA133 and LA136D) to prepare glue; carbon nanotube conductive agent, conductive carbon, softener (EC and PC), softener (NMP) and dispersion The agent is pre-mixed to obtain a solution; the glue, solution and remaining materials are uniformly mixed to obtain a slur...

Embodiment 2

[0052] Dual-ion battery positive electrode formula: 89% active material (graphite), 1% carbon nanotube conductive agent (including solid carbon nanotube CNT, ACNT), 2.5% conductive carbon (Super-P), 2.0% binder (LA133) , 2% binder (LA136D), 2% softener (EC and PC), 3% softener (NMP).

[0053] When preparing the dressing, an additional 0.5% of a dispersant is added, and the dispersant may specifically be a water-based conductive carbon black dispersant.

[0054] For the preparation method of the positive electrode of the dual-ion battery, refer to Example 1, which will not be repeated here.

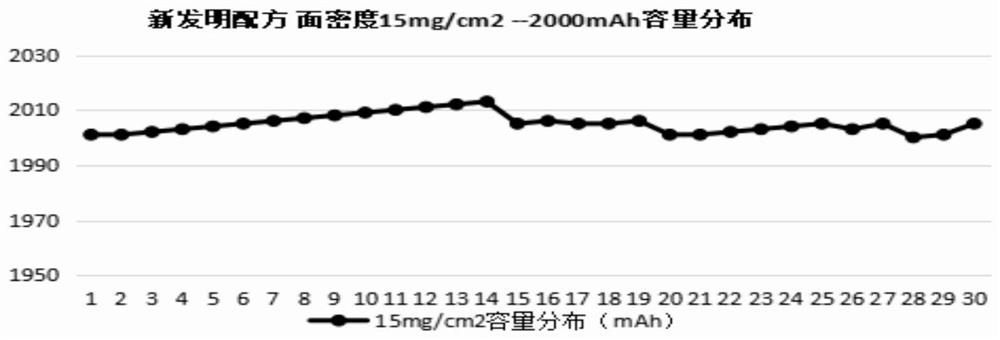

[0055] The comparison results of the areal density and capacity of the dual-ion battery positive electrode prepared by the above method are as follows

[0056] Table 2:

[0057]

[0058]

[0059] Table 2 Embodiment 2 and the capacity and surface density comparison table of comparative example

[0060] see Figure 3-4 , image 3 Electron micrograph of the positive electrode of the ...

Embodiment 3

[0063] Dual-ion battery positive electrode formula: 88.5% active material (graphite), 1% carbon nanotube conductive agent (including solid carbon nanotube CNT, ACNT), 2.5% conductive carbon (Super-P), 2.0% binder (LA133) , 2% binder (LA136D), 2% softener (EC and PC), 2% softener (NMP).

[0064] When preparing the dressing, an additional 0.5% of a dispersant is added, and the dispersant may specifically be a water-based conductive carbon black dispersant.

[0065] For the preparation method of the positive electrode of the dual-ion battery, refer to Example 1, which will not be repeated here.

[0066] The comparison results of the areal density and capacity of the dual-ion battery positive electrode prepared by the above method are as follows

[0067] table 3:

[0068]

[0069] Table 3 Example 3 and the capacity and areal density comparison table of comparative examples

[0070] see Figure 5-7 , Figure 5 , Figure 7 Electron micrograph of the positive electrode of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com