Temperature control method for fuel cell in fuel cell vehicle

A temperature control method and fuel cell vehicle technology, applied in fuel cells, circuits, electrical components, etc., can solve problems affecting the operation of fuel cells, water loss in proton exchange membranes, and large changes in water temperature, so as to improve program compatibility , shorten debugging time and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

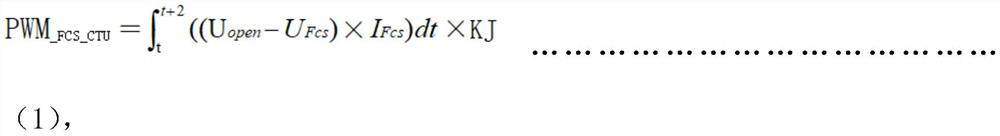

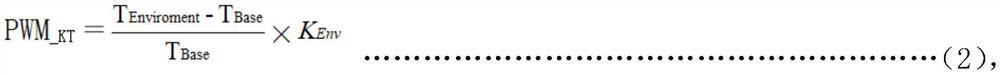

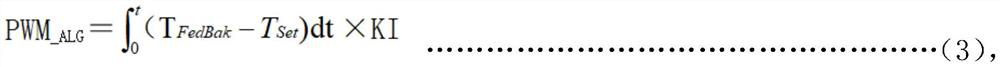

[0021] A method for controlling the temperature of a fuel cell in a fuel cell vehicle. During the operation of the vehicle, the vehicle controller collects the actual output voltage of the fuel cell, the actual output current of the fuel cell, the actual temperature of the water inlet of the fuel cell, and the ambient temperature in real time. According to the actual output voltage of the fuel cell, the actual output current of the fuel cell and the integral calculation of the open circuit voltage of the fuel cell, the fuel cell steady-state power temperature compensation duty cycle is obtained, and the fuel cell steady-state power temperature compensation duty cycle PWM _FCS_CTU Calculated according to formula (1):

[0022]

[0023] Among them, U open is the open circuit voltage of the fuel cell, U Fcs is the actual output voltage of the fuel cell, I Fcs is the actual output current of the fuel cell, t is the working time of the fuel cell; KJ is the conversion coefficien...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com