Polyamic acid composition and transparent polyimide film using same

A technology of polyamic acid and composition, which is applied in the field of transparent polyimide film, can solve problems such as easy bending or twisting, and achieve the effects of low yellowness, excellent mechanical properties, excellent physical properties and product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0162] The production example of the polyimide film when the above-mentioned thermal imidization method and chemical imidization method are used together will be described more specifically. A dehydrating agent and an imidization catalyst are put into a polyamic acid solution, and cast on a support body. After coating, the dehydrating agent and the imidization catalyst are activated by heating at 80 to 300° C., preferably at 150 to 250° C., thereby partially curing and drying the polyimide film.

[0163] The thickness of the polyimide film of the present invention thus formed is not particularly limited, and can be appropriately adjusted according to the field of application. For example, it may be in the range of 10 to 150 μm, preferably in the range of 10 to 80 μm.

[0164] The transparent polyimide resin film of the present invention can be applied to various fields, and specifically can be applied to substrates or protective films of flexible displays and the like. In thi...

Embodiment 1

[0169] 1-1. Production of polyamic acid composition

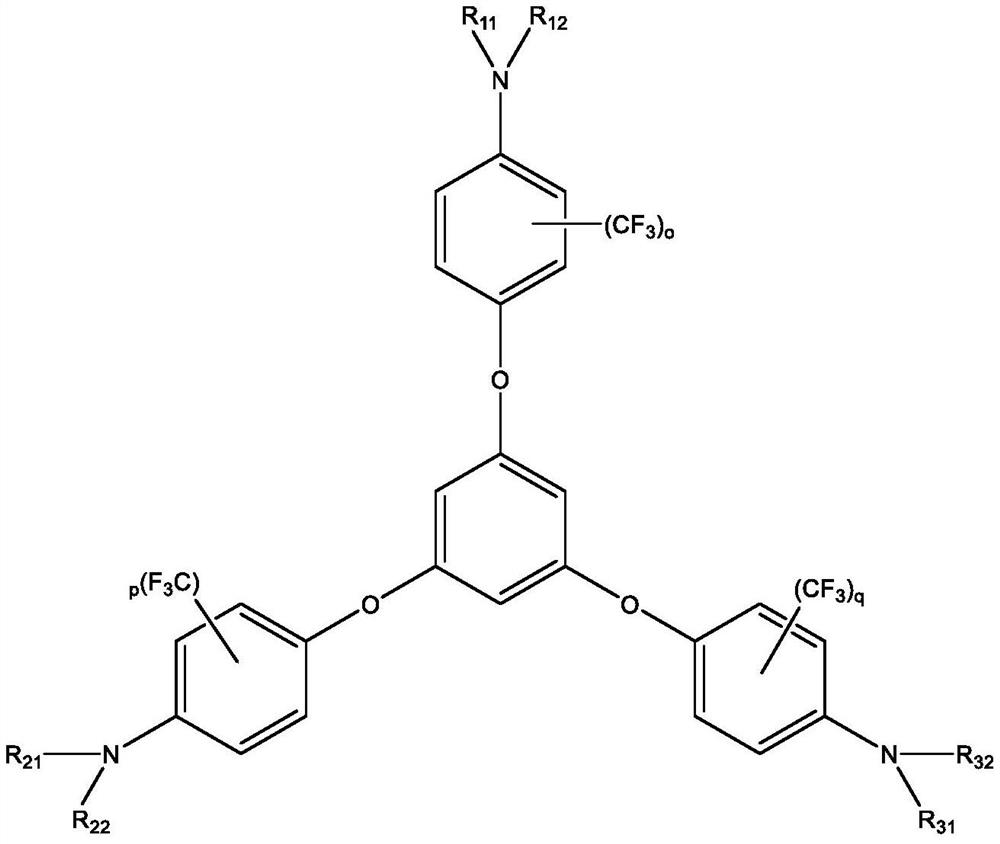

[0170] After charging 204.917 g of N,N-dimethylacetamide (N,N-Dimethylacetamide, hereinafter represented by DMAc) into a 500 ml 3-neck round bottom flask, the temperature of the reactor was raised to 50° C., and 2,2 '-Bis(trifluoromethyl)-4,4'-diaminobiphenyl (2,2'-Bis(trifluoromethyl)-4,4'-Diaminobiphenyl, hereinafter represented by TFDB) 15.0 g (95 mol%) and below 1.488 g (5 mol%) of the triamine represented by chemical formula 3a was stirred for 1 hour to completely dissolve the above-mentioned monomer. Next, 2,2-bis(3,4-dicarboxyphenyl)hexafluoropropane dianhydride (2,2-bis(3,4-dicarboxyphenyl)Hexafluoropropane dianhydride, hereinafter represented by 6FDA) and pyromellitic acid di After adding 17.523 g (80 mol%) and 2.151 g (20 mol%) of anhydride (Pyromellitic dianhydride, hereinafter represented by PMDA) sequentially, it cooled to 30 degreeC and dissolved.

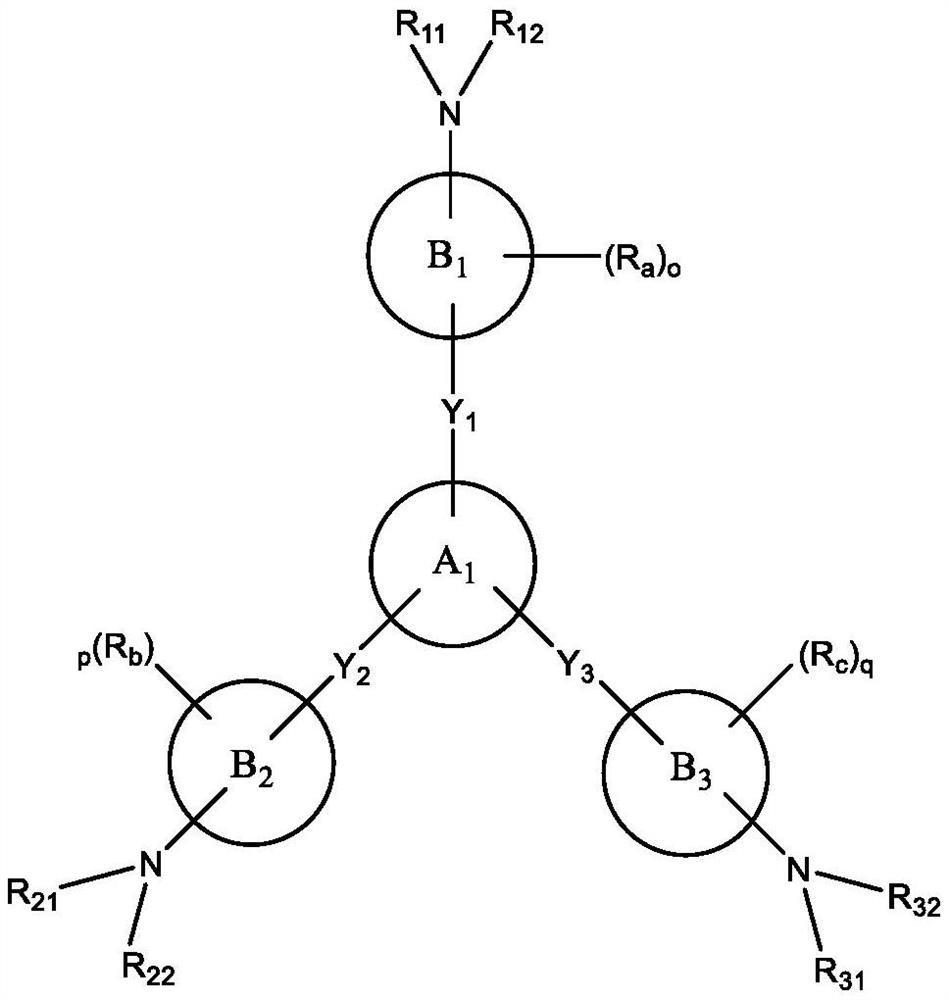

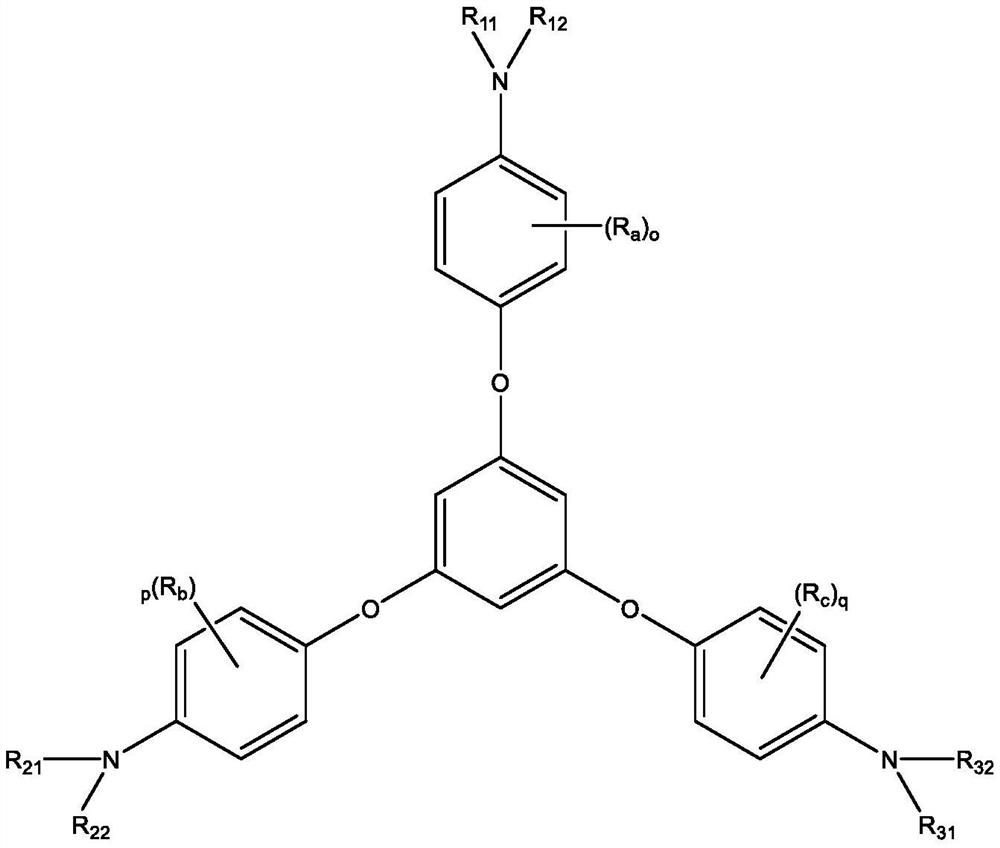

[0171] [chemical formula 3a]

[0172]

[0173] 1-2. ...

Embodiment 2

[0176] 1-1. Production of polyamic acid composition

[0177] Under the same conditions as above-mentioned Example 1, after loading DMAc 220.478g in the round-bottomed flask, the temperature of the reactor was raised to 50°C, and TFDB 15.0g (90mol%) and triamine 3.141g ( 10mol%), the above monomer was stirred for 1 hour to dissolve it completely. Next, 18.497 g (80 mol%) of 6FDA and 2.270 g (20 mol %) of PMDA were respectively added in sequence, and then cooled to 30° C. for dissolution.

[0178] 1-2. Production of transparent polyimide film

[0179] The production process of the colorless and transparent polyimide film was carried out in the same manner as in Example 1 above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com