Iron removal and mineral separation machine

A concentrator and iron rod technology, applied in the direction of solid separation, chemical instruments and methods, magnetic separation, etc., can solve the problems of unclean removal of iron, high cost, unfavorable industrial production, etc., to save time for collecting iron particles, The effect of reducing labor force and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

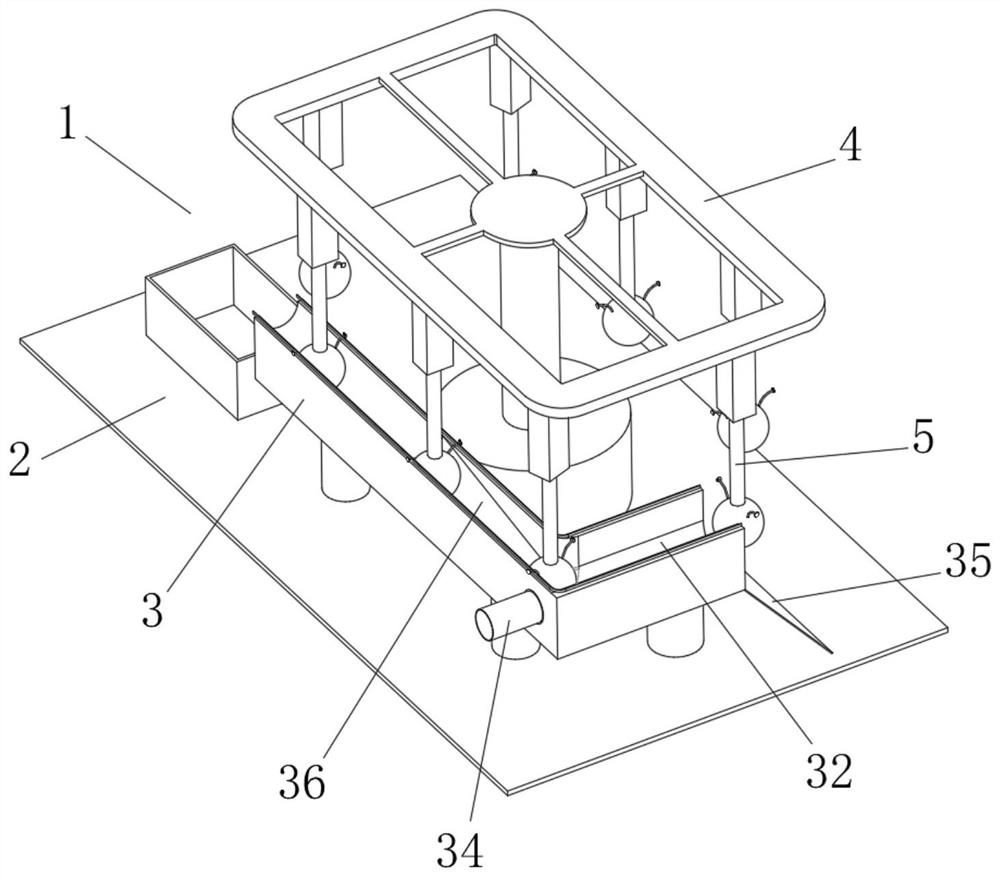

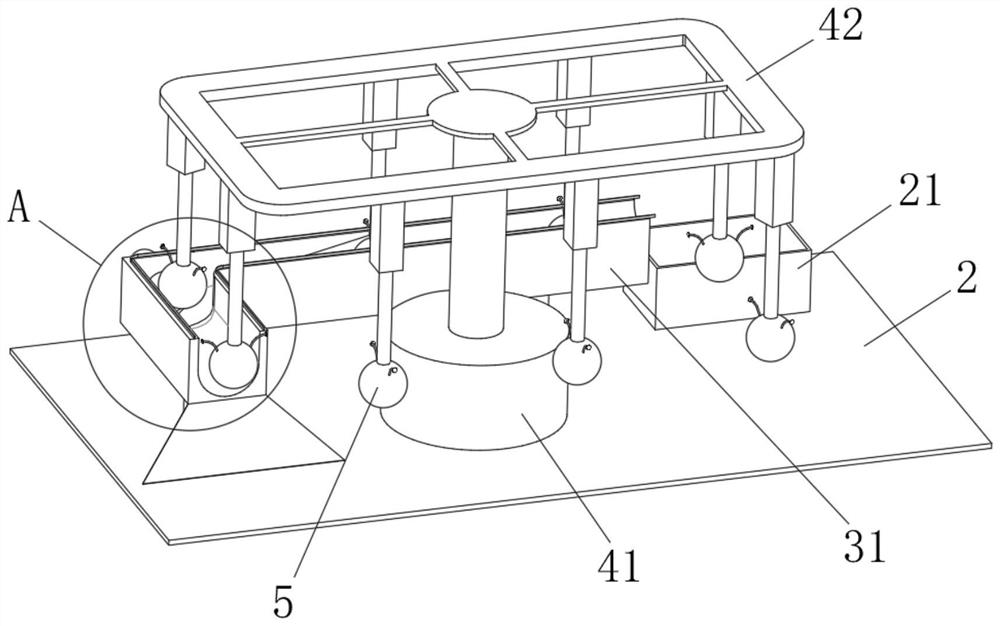

[0037] see Figure 1-4 , the present invention provides a technical solution: a mineral processing machine for removing iron, including a base 2, a mineral processing mechanism 3, a circulation mechanism 4 and a mineral processing machine body 1 for removing iron, and the mineral processing mechanism 3 includes a guide block 31, which guides The inside of the block 31 is provided with a guide groove 32, the top of the guide block 31 is fixedly connected with a conductive rail 33, the bottom receiving column of the guide block 31 is fixedly connected with the top of the base 2, and the left side of the guide block 31 is fixedly connected with a feed pipe 34 , the right end of the feed pipe 34 runs through the guide block 31 and extends to the inside of the guide groove 32, the right side of the guide block 31 is fixedly connected with the material receiving plate 35, the circulation mechanism 4 includes an engaging column 41, the bottom of the engaging column 41 is connected to ...

Embodiment 2

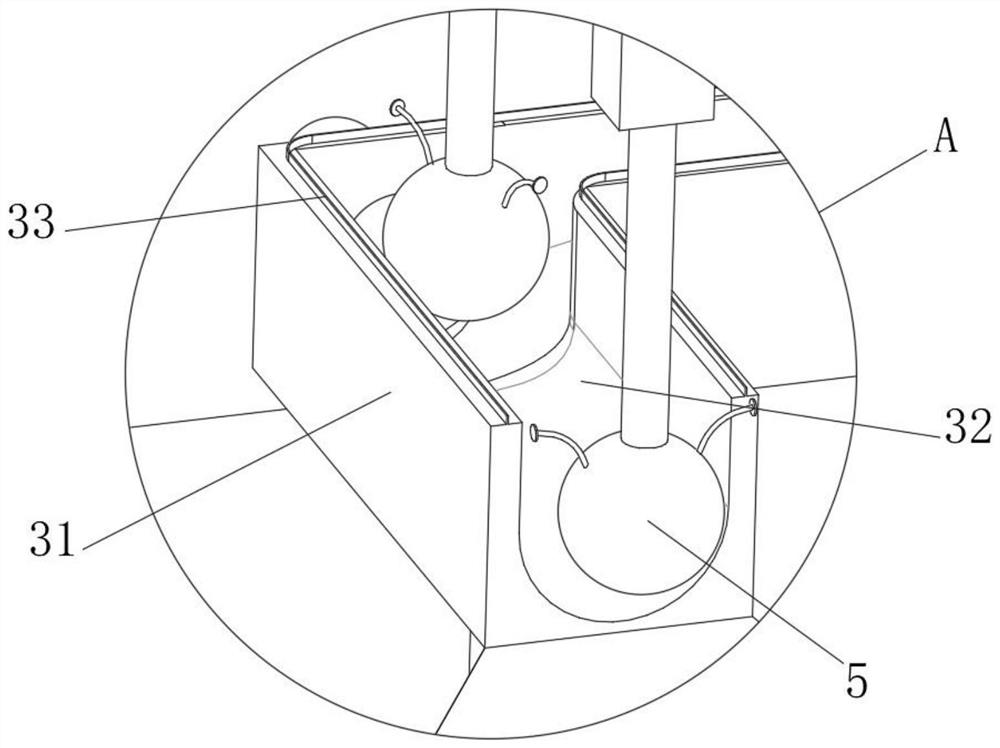

[0042] see Figure 1-5 On the basis of Embodiment 1, the present invention provides a technical solution: the iron removal mechanism 5 includes a sphere 51, the top of the sphere 51 is slidingly connected to the inside of the electric slide rail 42 through an elastic telescopic rod, and the inside of the sphere 51 is fixedly connected with Conductive sheet 52.

[0043] The inside of the ball 51 is fixedly connected with a conductive strip 53 , the bottom of the conductive strip 53 is electrically connected to the inside of the conductive sheet 52 , and the top of the conductive strip 53 is electrically connected to the inside of the conductive rail 33 through the rotating block.

[0044] The inside of the conductive sheet 52 is fixedly connected with an electromagnetic telescopic rod 54, and the bottom of the electromagnetic telescopic rod 54 is fixedly connected with a squeeze disc 55, and an insulating cavity 56 is opened inside the ball 51, and the outer side of the squeeze...

Embodiment 3

[0048] see Figure 1-6 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the iron-absorbing mechanism 58 includes an electromagnetic strip 581, and the bottom of the electromagnetic strip 581 is fixedly connected with a piston plate 582, and the bottom of the piston plate 582 passes through a spring assembly It is fixedly connected with the outer side of the ball center 57, and the outer side of the electromagnetic strip 581 is rotatably connected with an iron-absorbing rod 583 through a reset piece.

[0049] One end of the iron-absorbing rod 583 away from the electromagnetic strip 581 is connected with a rolling ball 584 through a rotating shaft, the outer side of the rolling ball 584 is slidingly connected with the inside of the sphere 51, and the outer side of the iron-absorbing rod 583 is fixedly connected with a wear-resistant bag 585, which The inside of the 585 is provided with a magnetic strip 586 , and the side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com