A kind of asphalt mixture for paving and preparation method thereof

An asphalt mixture and asphalt technology, applied in the field of asphalt mixture for paving and its preparation, can solve the problems of affecting the strong stability of pavement, tight effective compaction time, insufficient compaction of the mixture, etc., so as to prolong the effective compaction. Time, good compaction effect, good compactability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A road asphalt mixture, the preparation method of which is:

[0046]S1. Mix 40kg of crushed stone, 20kg of steel slag, 20kg of artificial sand, 12.5kg of mineral powder, 12.5kg of fly ash, and 50kg of expanded vitrified microbeads to obtain mixture A; wherein the particle size of the expanded vitrified microbeads is 0.5-2.5 mm;

[0047] S2. Mix 2kg organic warm-mixing agent, 10kg glass fiber, 3.5kg water-based epoxy resin emulsion and 0.7kg silane coupling agent to obtain mixture B; wherein the length of glass fiber is 3-9mm;

[0048] S3. Heat 15 kg of asphalt to 160° C., continue stirring, and put mixture A and mixture B into the asphalt, and mix them uniformly to obtain an asphalt mixture.

Embodiment 2-9

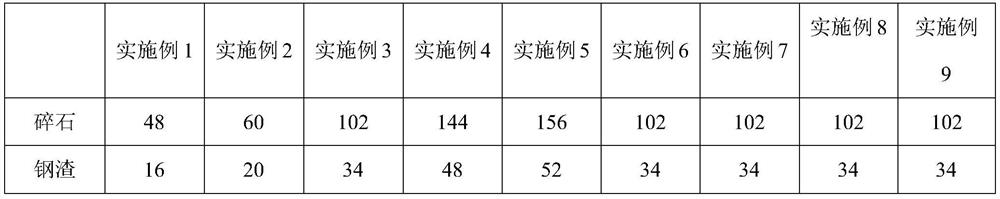

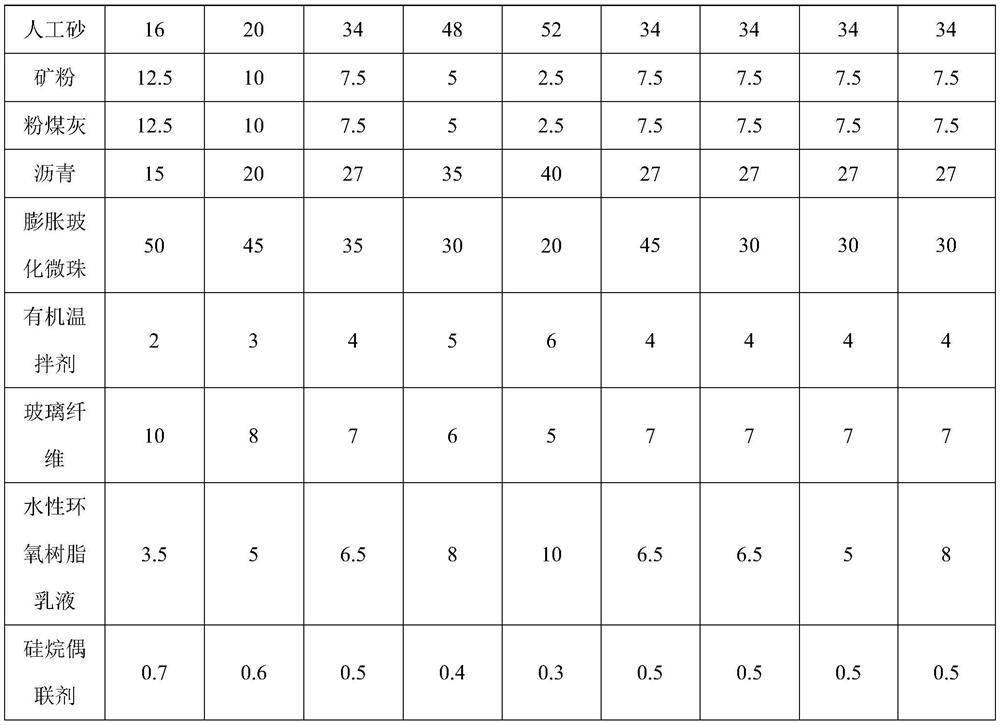

[0050] Different from Example 1, the consumption of each raw material is different, see Table 1 for details.

[0051] Table 1 embodiment 1-9 raw material proportioning table (kg)

[0052]

[0053]

Embodiment 10-11

[0055] Different from Example 3, in step S3, the asphalt is heated to 145°C and 180°C, respectively.

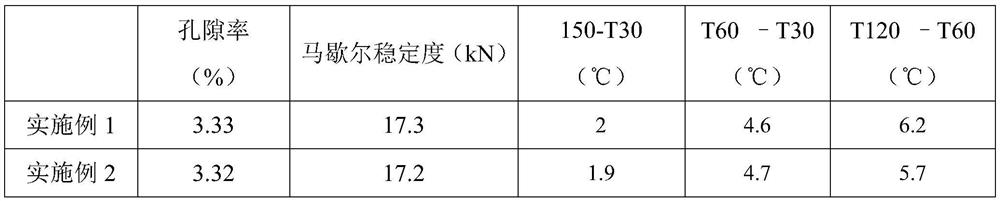

[0056] performance test

[0057] The porosity and Marshall stability of the compacted mixtures of the asphalt mixtures in Examples 1-11 were tested according to the "Highway Engineering Asphalt and Asphalt Mixture Test Regulations" JTG E20-2011. The test results are shown in Table 2.

[0058] To test the thermal insulation performance of the asphalt mixture, the test method is as follows: at room temperature, after heating the test sample to 160°C, stop heating and start stirring with a stirring speed of 10r / min. Measure the temperature three times at 30min and calculate the average to get T30 and record 160-T30 (30min cooling amount), measure the temperature three times at 60min and calculate the average to get T60 and record T60-T30, after 120min measure the temperature three times and calculate the average to get T120 and record T120–T60, the test results are shown in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com