Steel pipe pile group vibration piling method and positioning tool

A technology for positioning tooling and steel pipe piles, which is applied to sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as strength, adverse effects of installation orientation, long idle time of machinery, and high construction costs, so as to avoid idle machinery and installation The effect of good quality and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

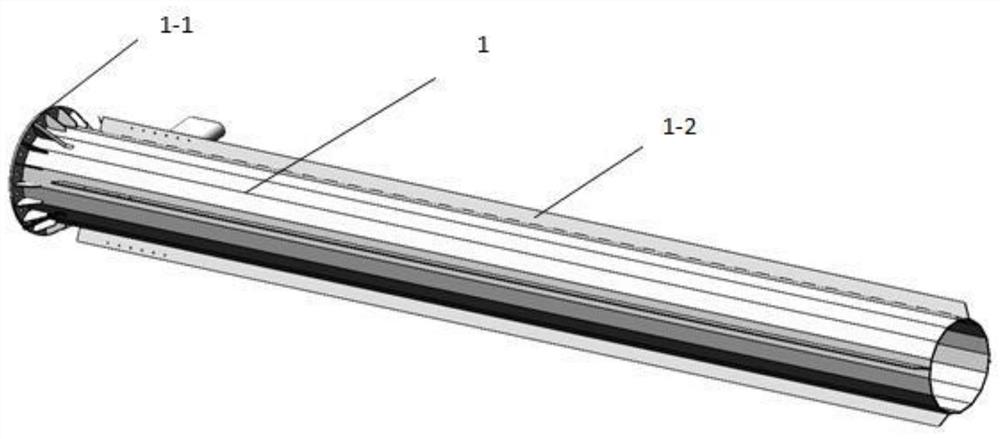

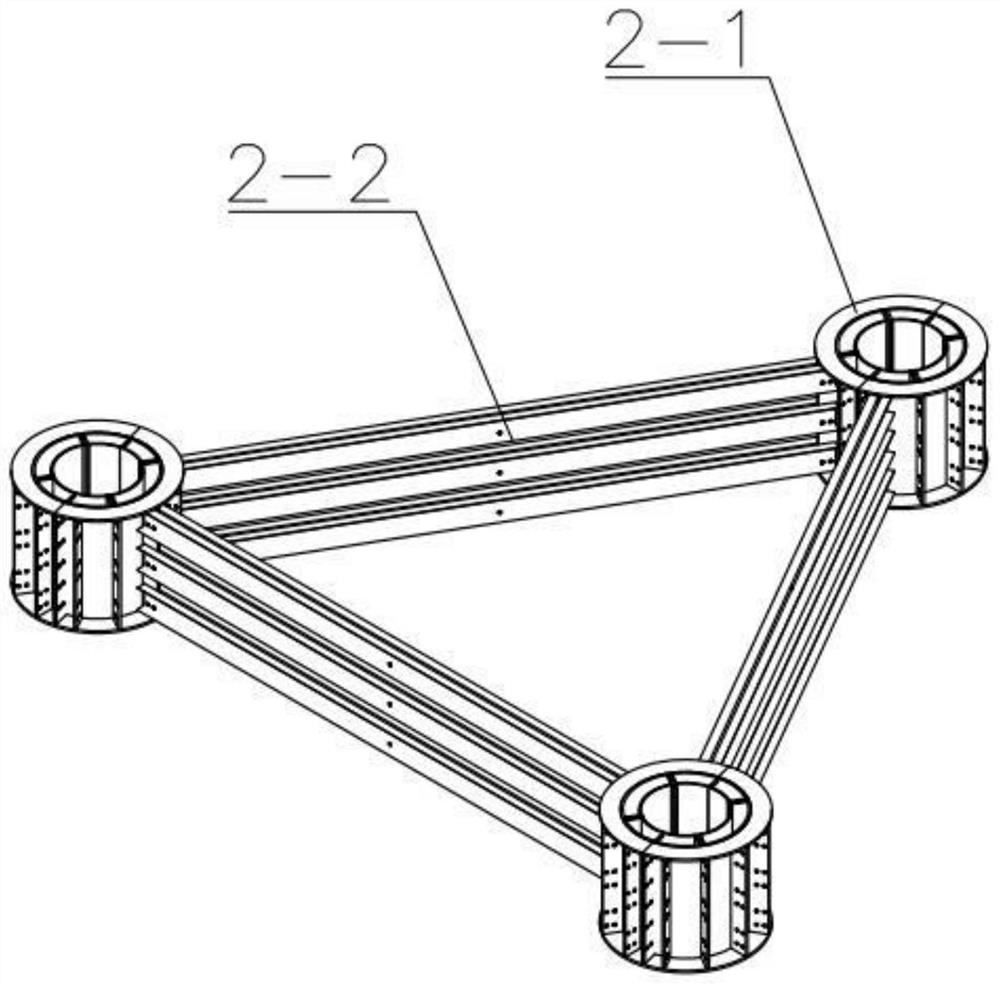

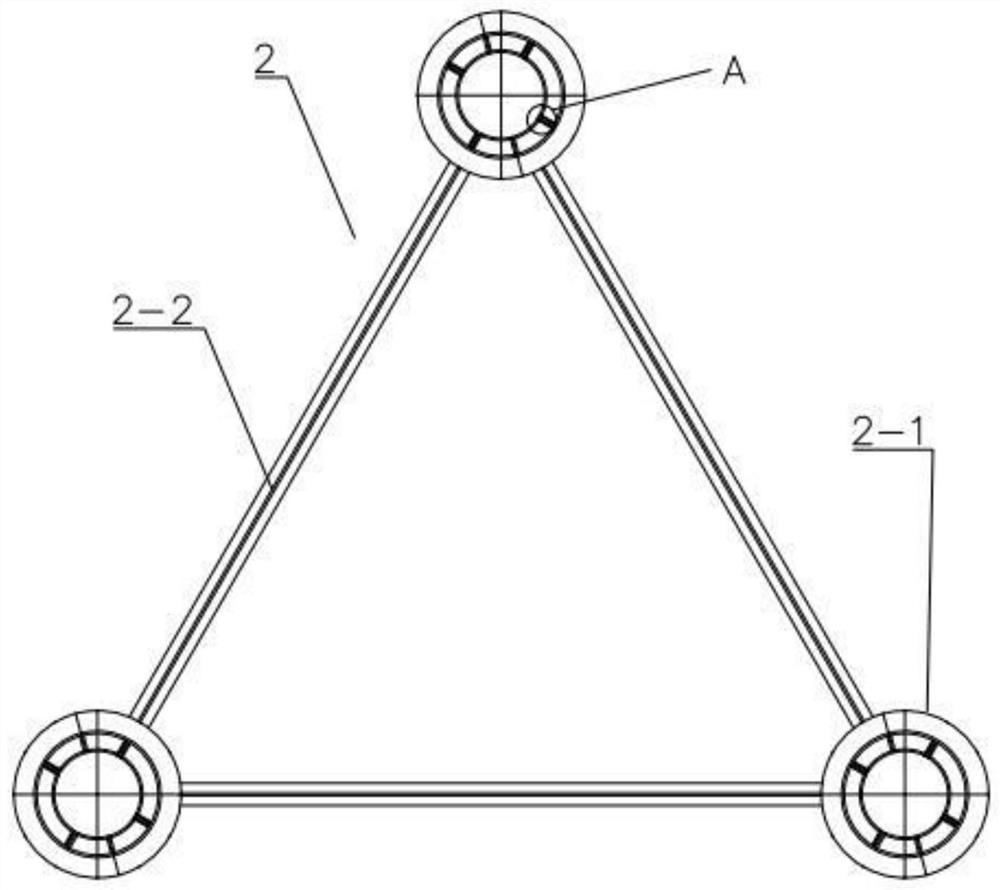

[0032] Such as figure 1 In the shown embodiment, a method for vibrating pile driving of steel pipe piles, in this embodiment, a three-pipe tower is taken as an example. The foundation of the three-pipe tower includes three steel pipe piles 1, and the span between the steel pipe piles is 2980mm. The diameter of the pipe pile is 600mm, and the length is 8m. Fully prepare man-machine materials before construction, including the following steps:

[0033] S1: Foundation survey, find out the topography and hydrology of the site and the interference with the artificial geological conditions of the steel pipe group piles, analyze the geological conditions of the site, and the survey is as follows:

[0034] For pile positions in rock layers, gravel layers, and gravel layers, replace the pile positions of the steel pipe group piles or perform foundation pretreatment on the site; foundation pretreatment includes: using a drilling rig to drill several holes in the pile positions of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com