Method for carrying out colored hair dyeing based on enzymatic oxidation of tyrosine derivatives

A technology of tyrosine and derivatives, applied in the field of chemistry, can solve problems such as unpleasant olfactory experience, inability to achieve other color dyeing, difficulty, etc., and achieve the effects of convenient and fast dyeing process, good biological adaptability, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A method for coloring hair based on enzymatic oxidation of tyrosine derivatives, comprising the steps of:

[0044] (1) washing human hair with water (the hair is white);

[0045] (2) dissolving the tyrosine derivative in PBS buffer solution with pH=7 to obtain a tyrosine derivative-PBS buffer solution with a concentration of 10 mg / mL;

[0046] (3) dissolving polyphenol oxidase in PBS buffer solution with pH=7 to obtain polyphenol oxidase-PBS buffer solution;

[0047] (4) Soak the hair after washing with water in the solution obtained in step (2); under stirring, add the polyphenol oxidase-PBS buffer solution obtained in step (3), so that the final concentration of polyphenol oxidase is 10U / mL, react at 37°C for 3 hours;

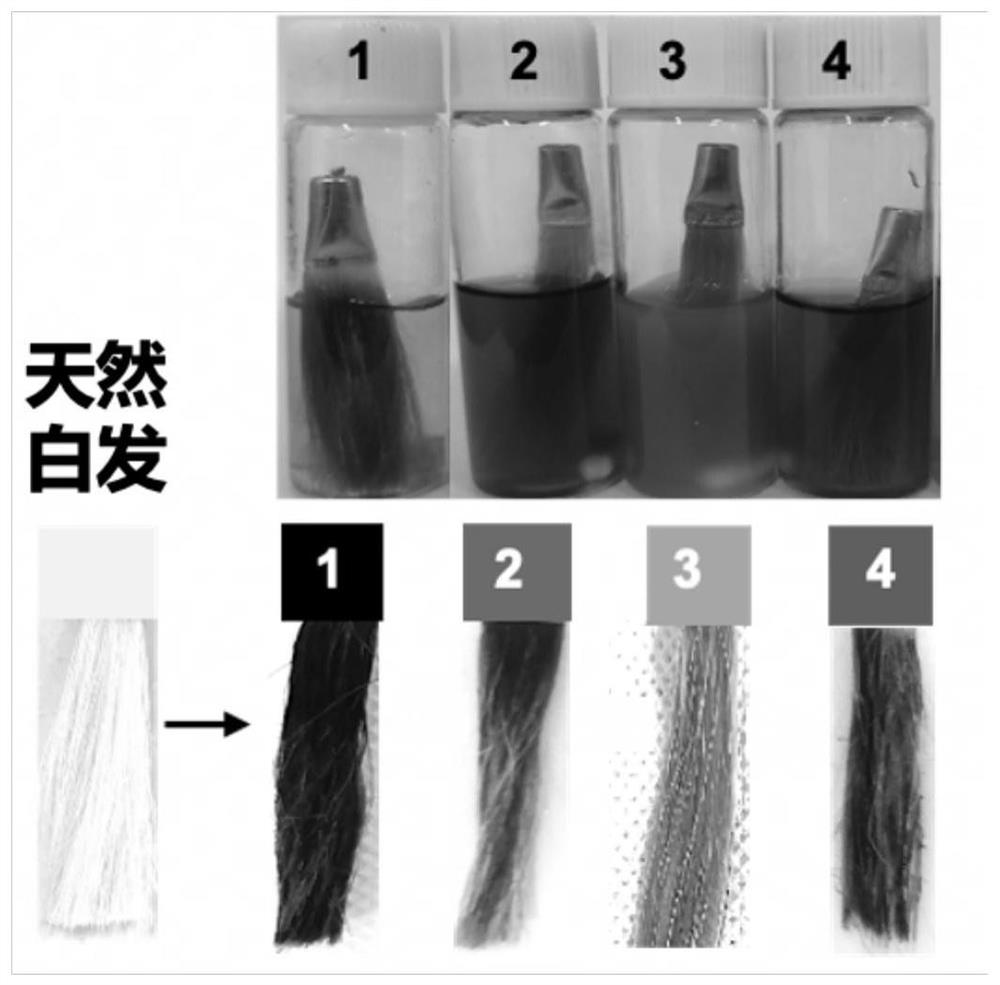

[0048] (5) Rinse with water, blot dry the surface moisture of the hair, and bake at 50°C for 8 minutes to fix the color. The resulting hair color is reddish brown, see figure 1 Sample No. 2.

[0049] Tyrosine derivatives are: N-tert-butoxycarbonyl...

Embodiment 2

[0053] A method for coloring hair based on enzymatic oxidation of tyrosine derivatives, comprising the steps of:

[0054] (1) washing human hair with water (the hair is white);

[0055] (2) Dissolving the tyrosine derivative in PBS buffer solution with pH=6.5 to obtain a tyrosine derivative-PBS buffer solution with a concentration of 1 mg / mL;

[0056] (3) dissolving polyphenol oxidase in PBS buffer solution with pH=6.5 to obtain polyphenol oxidase-PBS buffer solution;

[0057] (4) Soak the hair after washing with water in the solution obtained in step (2); under shaking, add the polyphenol oxidase-PBS buffer solution obtained in step (3), so that the final concentration of polyphenol oxidase is 8U / mL, react at 40°C for 3 hours;

[0058] (5) Rinse with water, blot dry the surface moisture of the hair, and dry at 40°C for 10 minutes to fix the color. The resulting hair color is light pink, see figure 1 Sample No. 3.

[0059] The tyrosine derivative is: 9-fluorenylmethoxycar...

Embodiment 3

[0063] A method for coloring hair based on enzymatic oxidation of tyrosine derivatives, comprising the steps of:

[0064] (1) washing human hair with water (the hair is white);

[0065] (2) Dissolving the tyrosine derivative in PBS buffer solution with pH=7 to obtain a tyrosine derivative-PBS buffer solution with a concentration of 20 mg / mL;

[0066] (3) dissolving polyphenol oxidase in PBS buffer solution with pH=7 to obtain polyphenol oxidase-PBS buffer solution;

[0067] (4) Soak the hair after washing with water in the solution obtained in step (2); under stirring, add the polyphenol oxidase-PBS buffer solution obtained in step (3), so that the final concentration of polyphenol oxidase is 12U / mL, react at 25°C for 2 hours;

[0068] (5) Rinse with water, blot dry the surface moisture of the hair, and bake at 60°C for 5 minutes to fix the color. The resulting hair color is auburn, see figure 1 Sample No. 4.

[0069] The tyrosine derivatives are: benzyloxycarbonyl-L-tyro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com