A kind of multifunctional recycled light-transmitting concrete construction and production equipment and production method

A technology of light-transmitting concrete and a manufacturing method, which is applied in metal processing, manufacturing tools, optical fiber/cable installation, etc., can solve problems such as inconvenient operation, high production cost, and complicated equipment manufacturing, so as to avoid false vibration and improve Drilling efficiency, the effect of improving the light transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

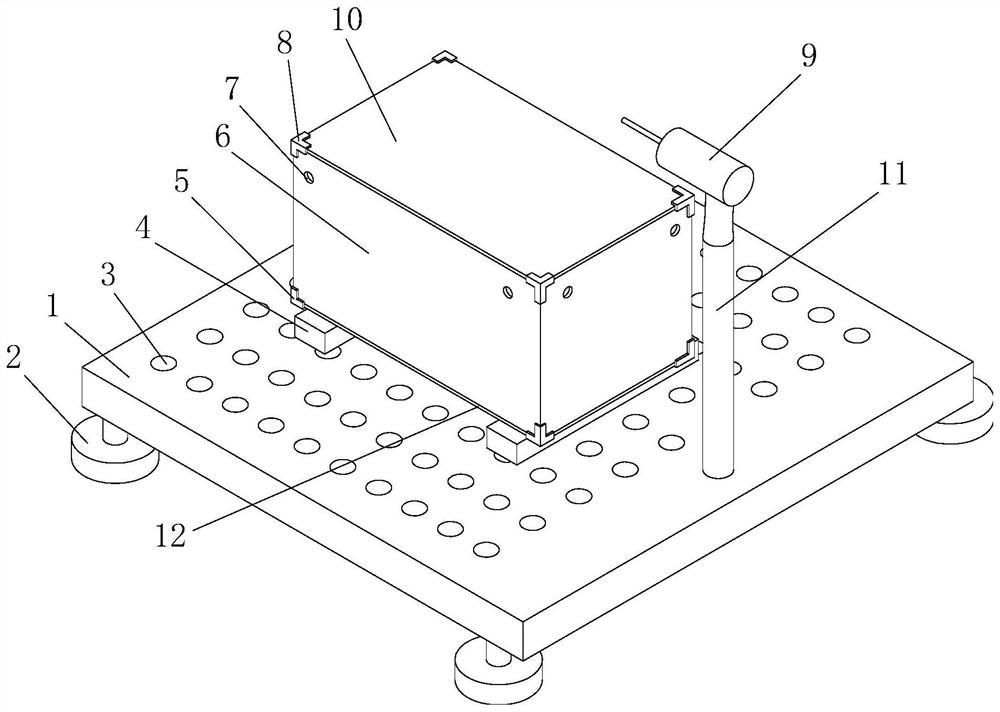

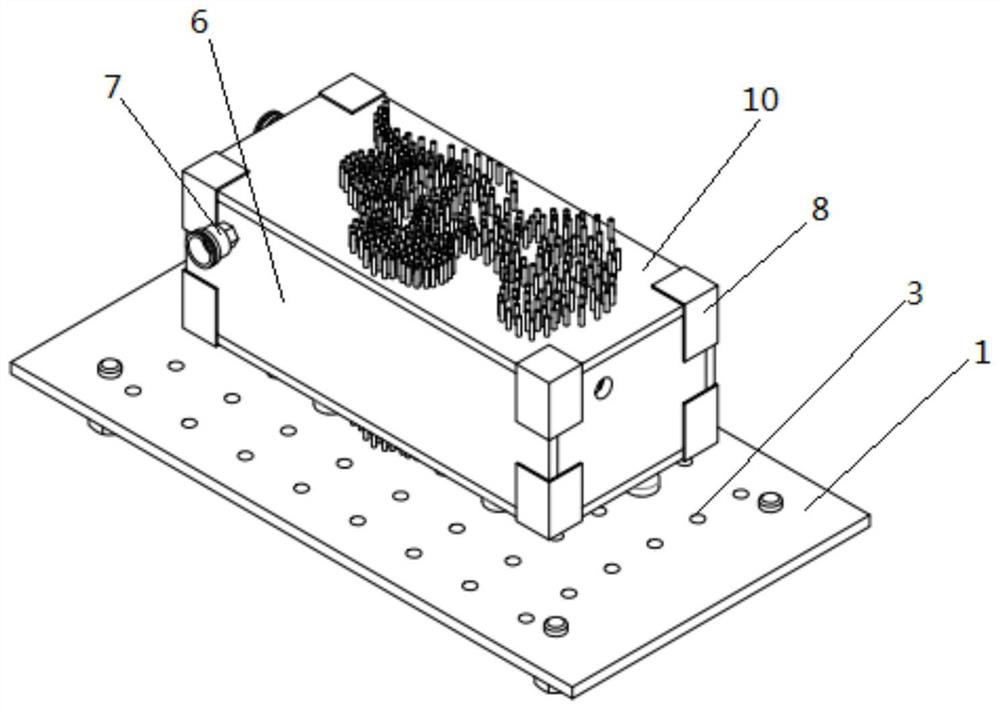

[0046] see Figure 1-4 , the present invention provides a technical solution: a multifunctional recycled light-transmitting concrete construction production equipment and production method, including a workbench 1, four workbench bases 2 are fixedly installed on the lower side of the workbench 1, and the upper side of the workbench 1 There are several movable pillow bars 4 placed on the side, and the movable pillow block can be adjusted in height by adjusting its own thread. The upper side of several movable pillow bars 4 is placed with a lower formwork 12, and the four corners of the lower formwork 12 are provided with four The lower fixing part 5 is provided with four side templates 6 on the four lower fixing parts 5, and the upper side of the four side templates 6 is placed with an upper template 10, and the four corners of the upper template 10 are provided with upper fixtures 8, and the four upper fixtures 8 are respectively fixedly connected with the four side formworks ...

Embodiment 2

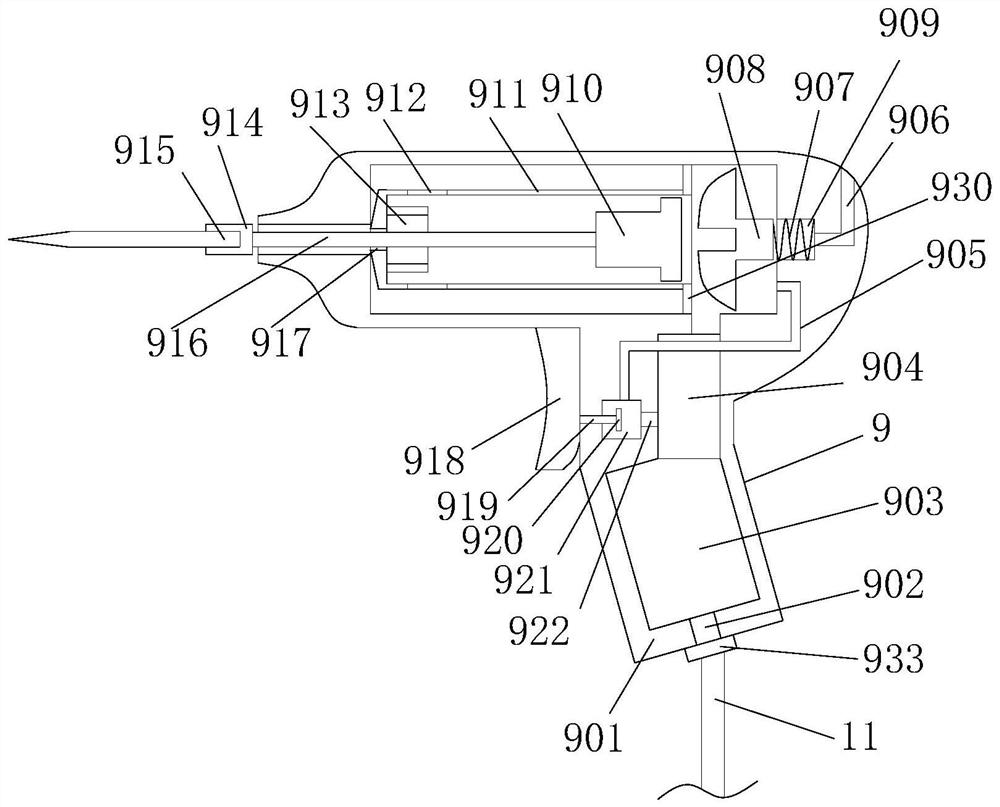

[0061] On the basis of Example 1, please refer to Figure 5-7, including a square tube 911, the right end of the square tube 911 is fixedly connected to the left side of the piston 910, the square tube 911 is movably connected with a moving block 931, and the moving block 931 is movably socketed with a pressure spring b934, a pressure spring b934, and a pressure spring b934 The right end is fixedly connected to the left side of the square pipe 911, the left end of the pressure spring b934 is fixedly installed with a connecting block 927, the right side of the connecting block 927 is fixedly connected to the left side of the moving block 931, and the right end of the thimble 916 is connected to the left side of the connecting block 927 through a bearing Movably connected, the left inner wall of the fixed tube 911 is fixedly equipped with a fixed plate 925, the thimble 916 is fixedly sleeved with a screw 926, the screw 926 moves through the fixed plate 925, four groups of hemisph...

Embodiment 3

[0066] On the basis of Example 2, please refer to Figure 8 , the surface of the gun body 901 is provided with an air outlet 935, the air outlet 935 communicates with the gun compartment of the gun body 901, one end of the air inlet pipe 11 is connected to the external air pressure bottle, and the other end is connected to the gas storage chamber 903, when the trigger 918 is released, the gas passes through The air delivery pipe 905 and the air storage chamber 903 form a balance at the valve piston 908; after the trigger 918 is pulled, there is no air pressure in the air delivery pipe 905, and the air pressure in the air storage chamber 903 pushes the valve piston 908 to close the cavity, and pushes the piston 910 to move forward. Like this just can drive thimble 916 to move to the left, just can drive screw rod 926 to move to the left, thereby can drive thimble 916 to rotate by fixed plate 925, like this just can drive connection cap 914 to rotate, thereby can drive perforatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com