Olefinic carbon material dispersion liquid and application thereof

A technology of olefinic carbon materials and dispersion liquid, which is applied in the direction of single-component polyamide rayon, single-component synthetic polymer rayon, textiles and papermaking, etc., can solve the problems affecting the comprehensive performance and agglomeration of composite materials, and achieve Excellent dispersion effect, speed up upgrading and innovation, and improve the effect of comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]1) Take 80 g of DMAc solution in a beaker, add 2.5 g of heterocyclic aramid polymerization liquid, and stir mechanically for 30 minutes to obtain a DMAc solution of heterocyclic aramid.

[0051] The heterocyclic aramid polymerization solution is prepared as follows: Dissolve an appropriate amount of p-phenylenediamine and 2-(4-aminophenyl)-5-aminobenzimidazole in DMAc, adjust the solid content to 3% to 5%, and then Add terephthaloyl chloride at low temperature to carry out low-temperature copolymerization, the low temperature used is -10-5°C, and the viscosity of the polymerization liquid is adjusted to be between 30,000 and 150,000 centipoise.

[0052] 2) Take 20 g of DMAc solution in a beaker, add 0.5 g of multi-walled carbon nanotubes, and disperse by ultrasonic for 40 min.

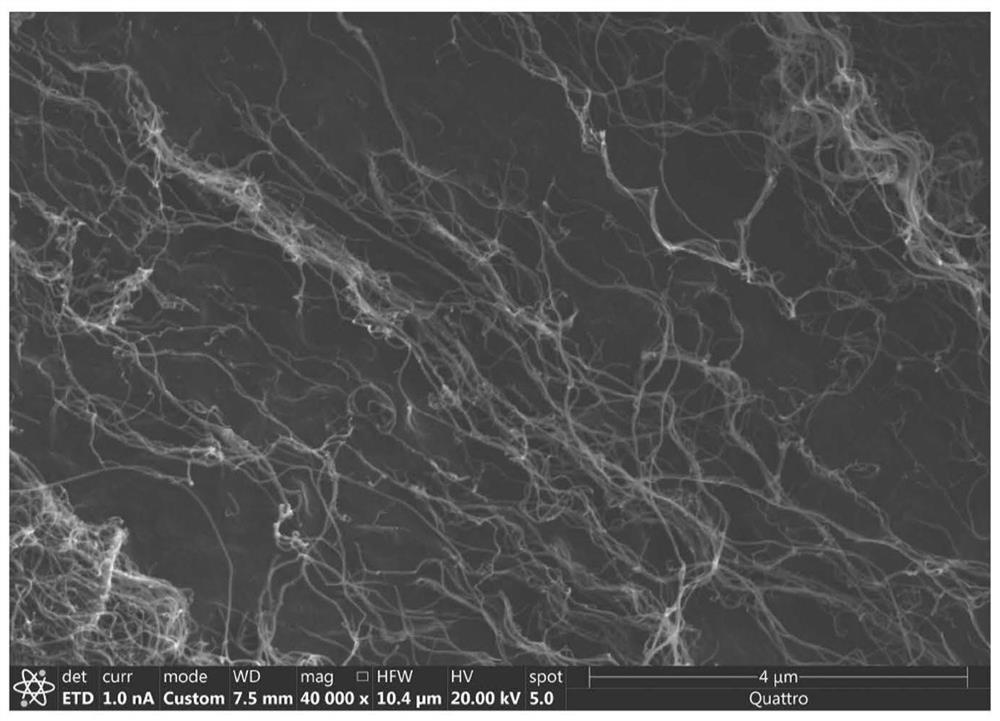

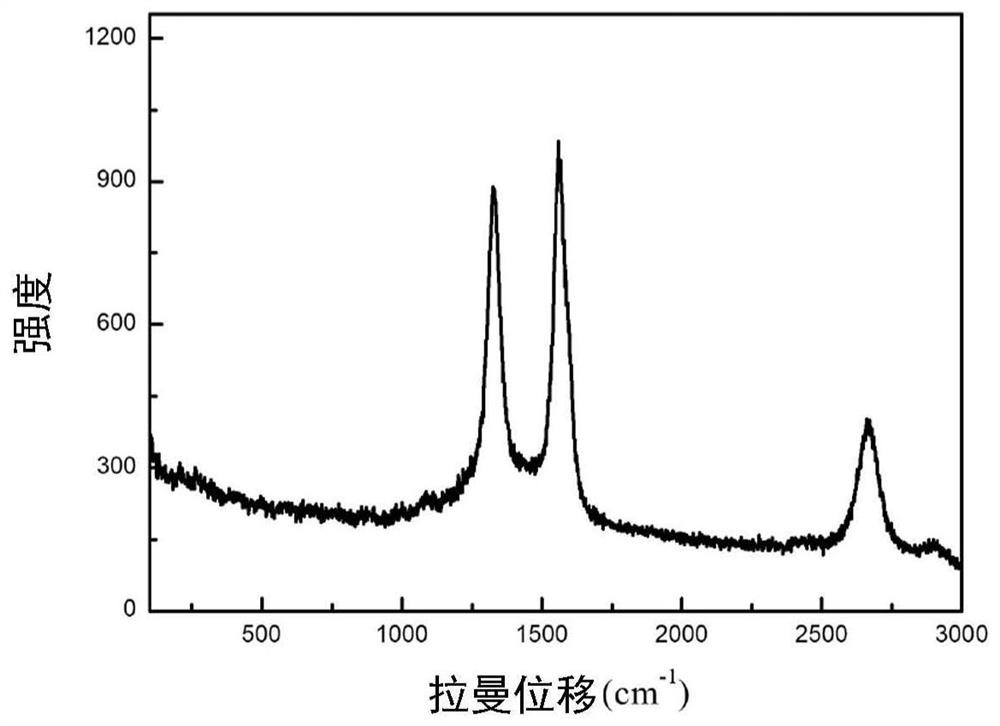

[0053] figure 1 is a scanning electron microscope (SEM) image of the multi-walled carbon nanotube. figure 2 is the Raman spectrum of the multi-walled carbon nanotube.

[0054] 3) The above tw...

Embodiment 2

[0056] 1) Take 80 g of NMP solution in a beaker, add 2 g of meta-aramid polymer solution provided by Zhonglan Chenguang Chemical Research and Design Institute Co., Ltd., and disperse it ultrasonically for 30 minutes to obtain a meta-aramid NMP solution.

[0057] 2) Take 20g of NMP solution in a beaker, add 0.3g of graphene, and ultrasonically disperse for 40min.

[0058] 3) Mix the above two, and perform a ball milling dispersion treatment for 60 minutes to obtain a uniform dispersion of graphene.

Embodiment 3

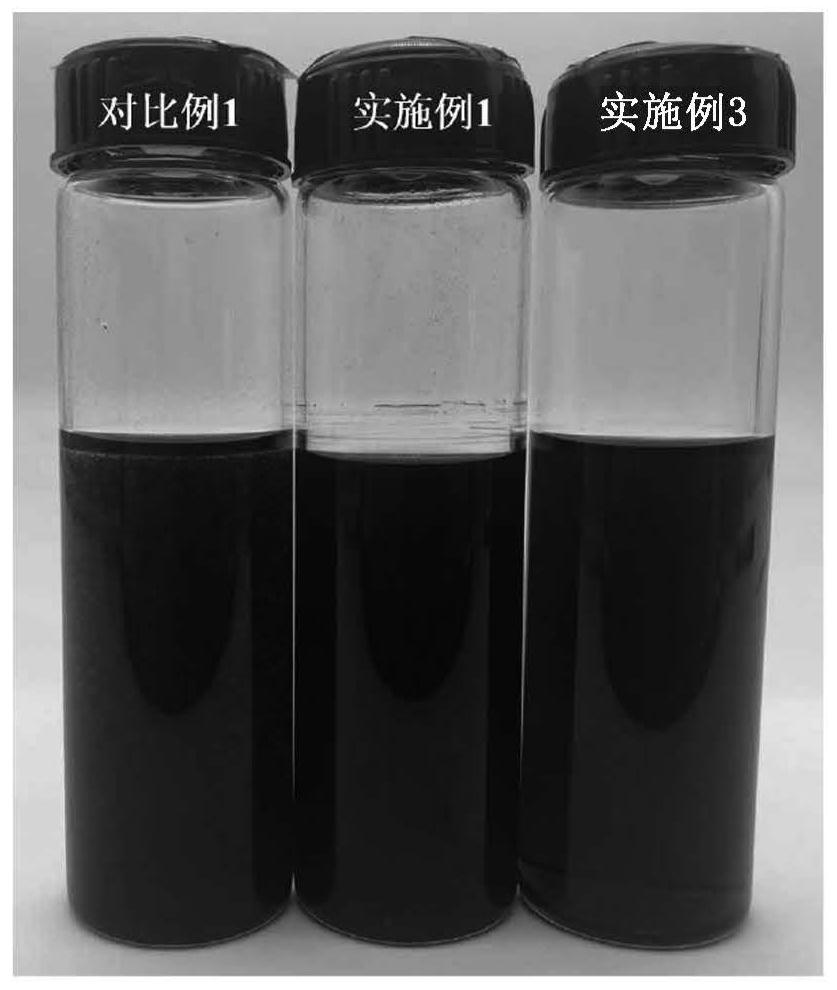

[0062] The multi-walled carbon nanotube dispersion was prepared by the method of Example 1, except that aminated carbon nanotubes were added in step 2).

[0063] image 3 It is a comparison photo of the multi-walled carbon nanotube dispersion in Example 1, Comparative Example 1, and Example 3. It can be seen from the figure that the multi-walled carbon nanotube dispersion liquid and the aminated multi-walled carbon nanotube dispersion liquid dispersed by the heterocyclic aramid polymer solution are uniform and stable, and both present a good dispersion state. However, the dispersibility of the multi-walled carbon nanotube dispersion without adding the heterocyclic aramid polymerization solution is very poor, and there is more sedimentation after the dispersion work is completed.

[0064] Figure 4 It is the ultraviolet-visible absorption spectrum of the dispersion liquid stored for a period of time (1d, 7d, 9d, 11d, 12d, 14d, 20d, 22d) in Example 1. It can be seen that with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com