Digital product processing and recycling device

A recovery device and technology for digital products, applied in cleaning methods using tools, cleaning methods and utensils, gas treatment, etc., can solve the problems of toxic exhaust gas, long time consumption, heavy workload, etc., to reduce the interference of impurities and increase the contact area , Reduce the difficulty and cost of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

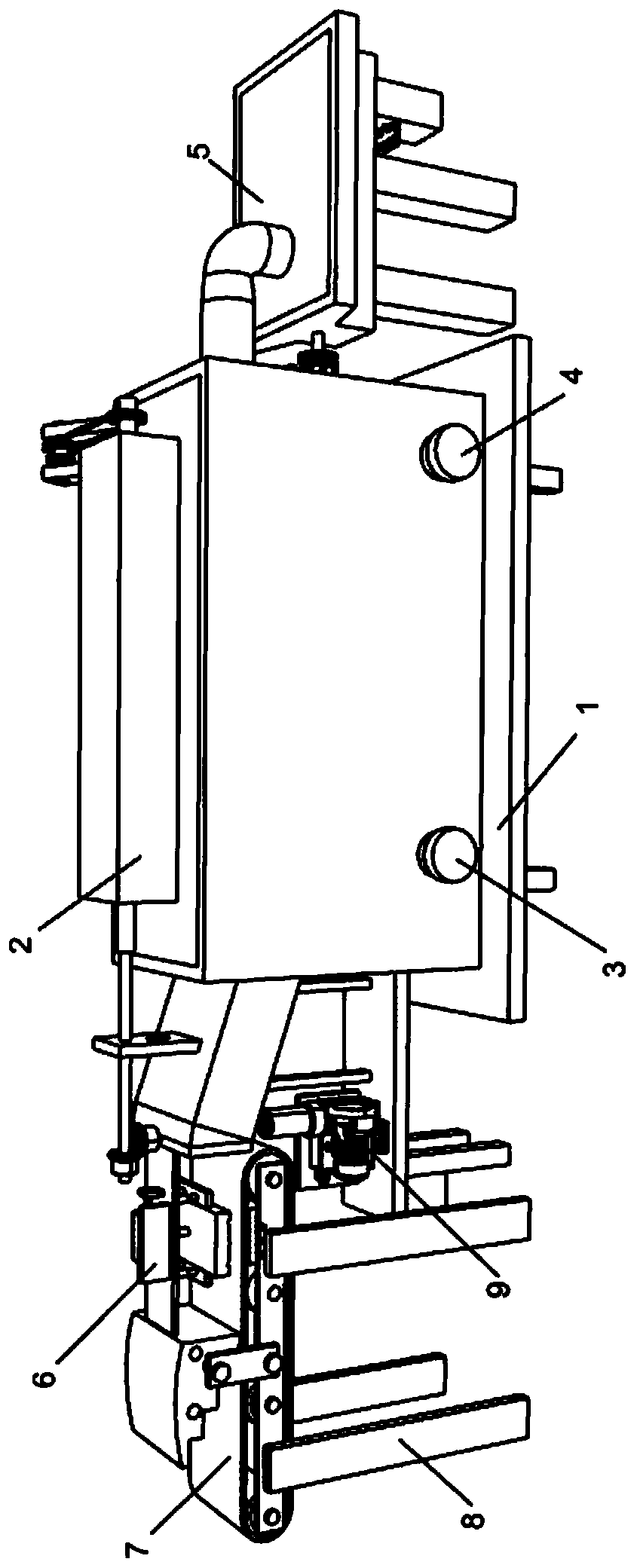

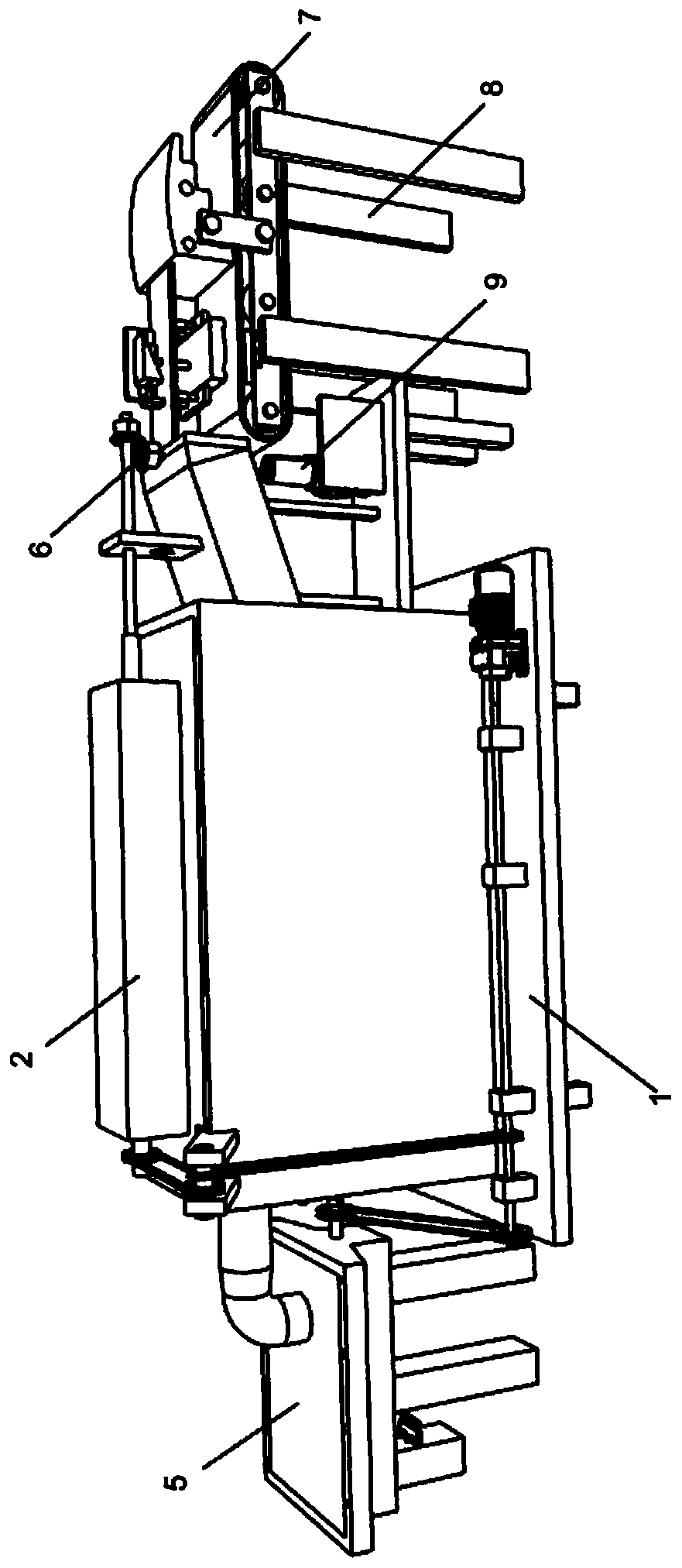

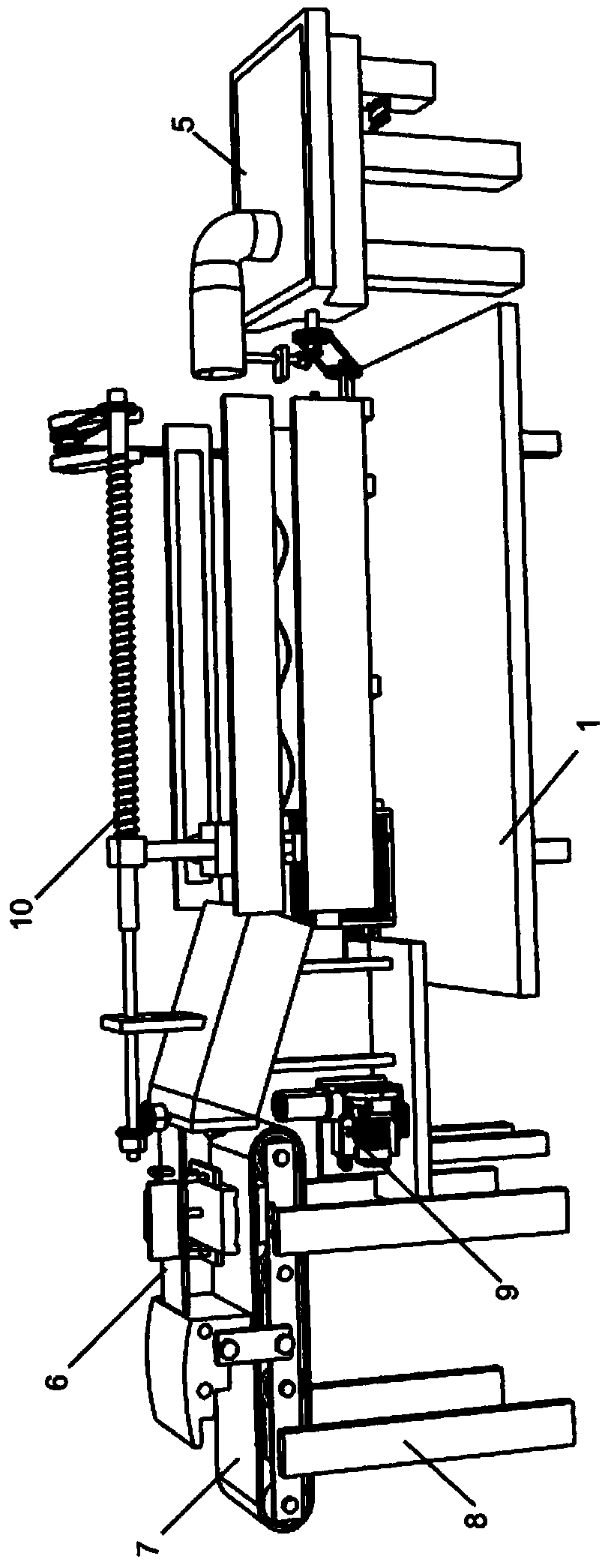

[0027] A digital product processing and recycling device, such as Figure 1-7 As shown, it includes a bottom plate 1, a synthesis device shell 2, a liquid raw material inlet 3, a treatment liquid outlet 4, an exhaust gas recovery device 5, a stacked paper separation device 6, a conveyor belt 7, a foot 8, a fan 9 and a titanium dioxide recovery device 10; the top of the bottom plate 1 The middle part is bolted to the synthesis device shell 2; the left side of the front bottom of the synthesis device shell 2 is socketed with the liquid raw material inlet 3; the front bottom right side of the synthesis device shell 2 is socketed with the treatment liquid outlet 4; the right top of the synthesis device shell 2 The middle part is connected with the tail gas recovery device 5; the left middle top of the synthesis device shell 2 is connected with the paper stack separation device 6; the left middle bottom of the synthesis device shell 2 is connected with the fan 9 through a support pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com