Thermosetting vulcanized natural rubber modified asphalt material and preparation method thereof

A technology of natural rubber modification and asphalt materials, which is applied in building insulation materials, building components, buildings, etc., can solve the problems of limited performance improvement, achieve the effects of reducing preparation difficulty, reducing temperature sensitivity, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparation of blank and comparative examples

[0042] (1) Blank example

[0043] Prepare according to the following steps: take 1000g of 70# base asphalt, heat and melt it in an oven at 140°C, add 40g of naphthenic oil, stir for 5min at 140°C and 500rpm, and then add 0.1% natural rubber per minute Emulsion speed After adding 80g of natural rubber emulsion, keep stirring during the addition process, stop stirring for 5 minutes after the addition is complete, and continue to develop in an oven at 110°C until no foam is generated to obtain a blank sample of natural rubber asphalt.

Embodiment 2

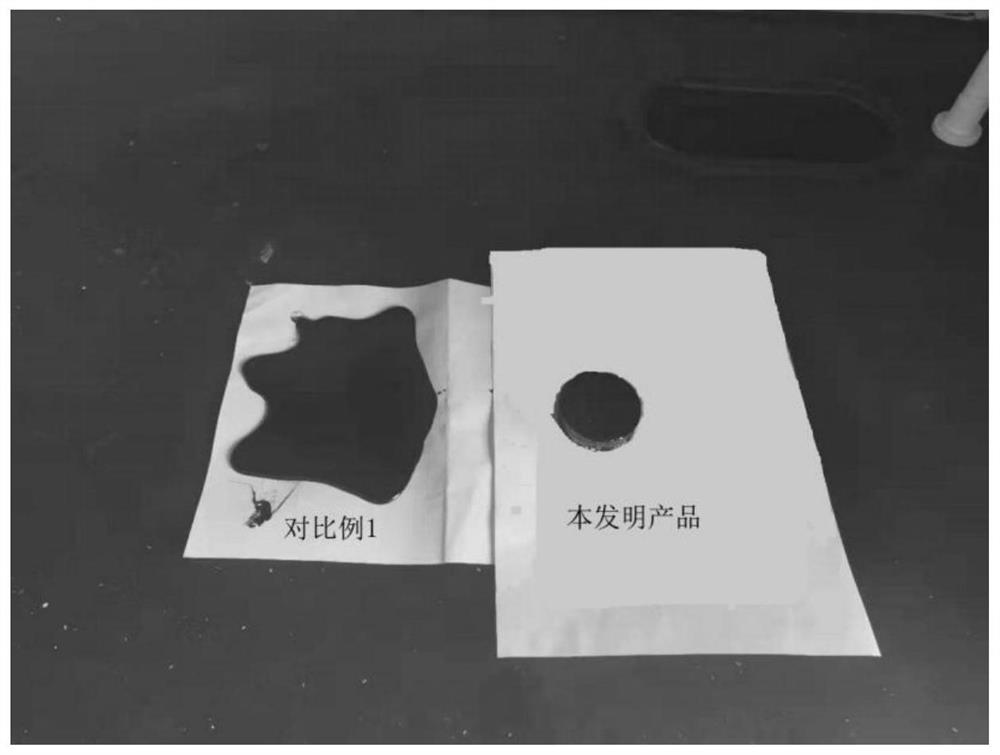

[0066] Embodiment 2 product performance test

[0067] Because the material of the present invention belongs to thermosetting material, the test mode of asphalt is not applicable, so evaluate the experimental group of the present invention that embodiment 1 makes according to the detection method of thermosetting rubber (specifically operate according to ASTM D638-2003 plastic tensile property standard test method) For samples 1 to 8, blank examples, and comparative samples, the tensile strength and elongation at break of the samples were tested at 23°C, and the softening point was added to characterize their thermosetting characteristics. The measured results are shown in Table 4: the thermosetting rubber asphalt material prepared by the present invention can greatly improve the performance of asphalt relative to thermoplastic vulcanized natural rubber modified asphalt, and the tensile strength and elongation at break are significantly improved. The low temperature cracking re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com