Pellet granularity monitoring control system based on volume analysis and method

A technology of granular monitoring and control system, applied in general control system, control/regulation system, program control, etc., can solve the problems of long debugging cycle and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] DETAILED DESCRIPTION OF THE DRAWINGS

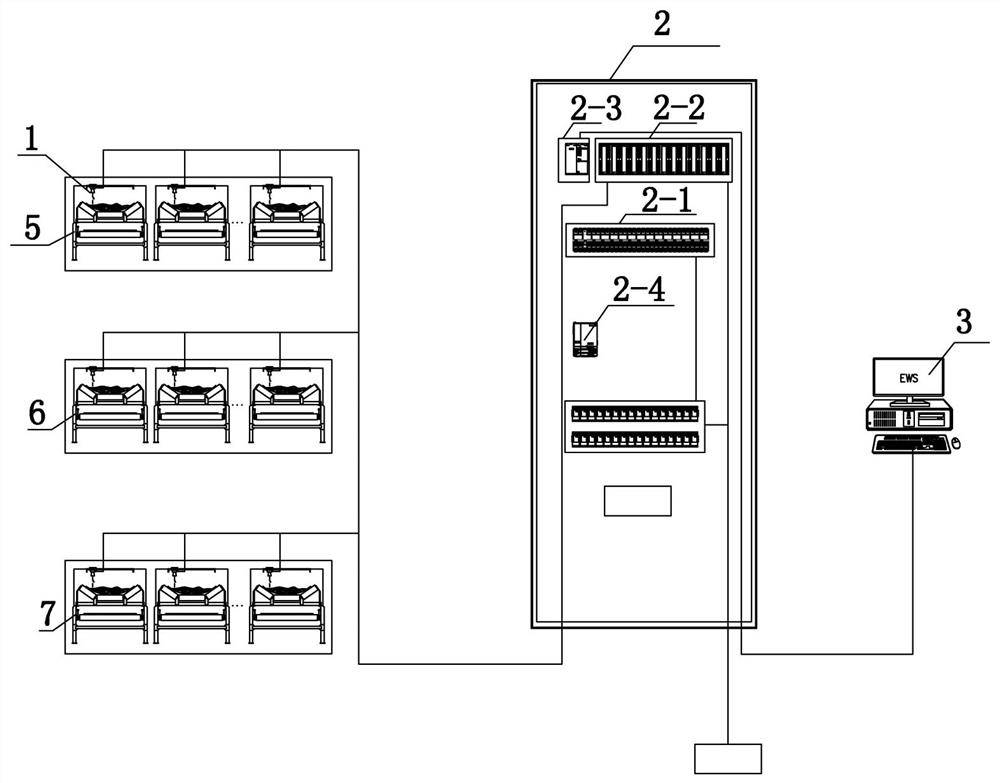

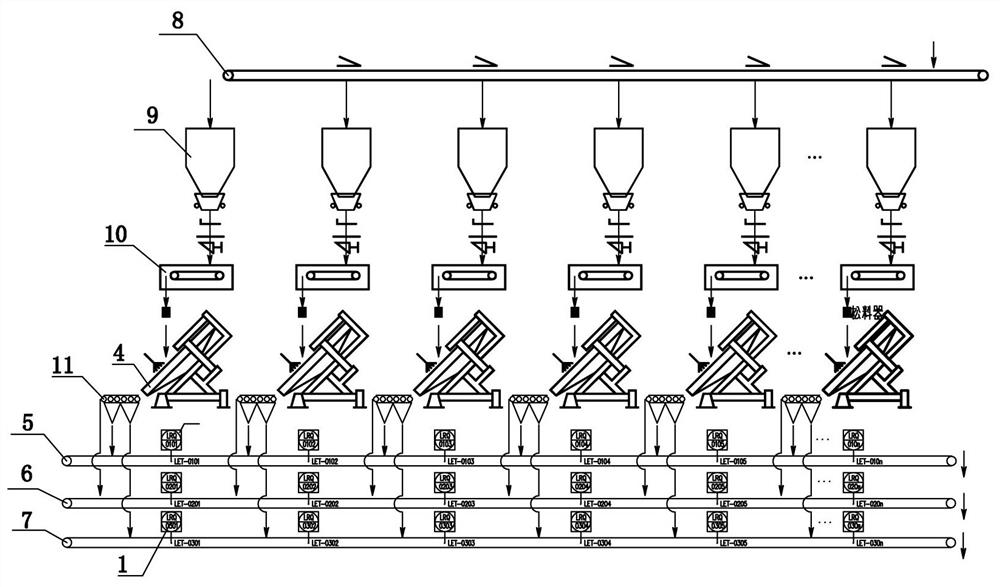

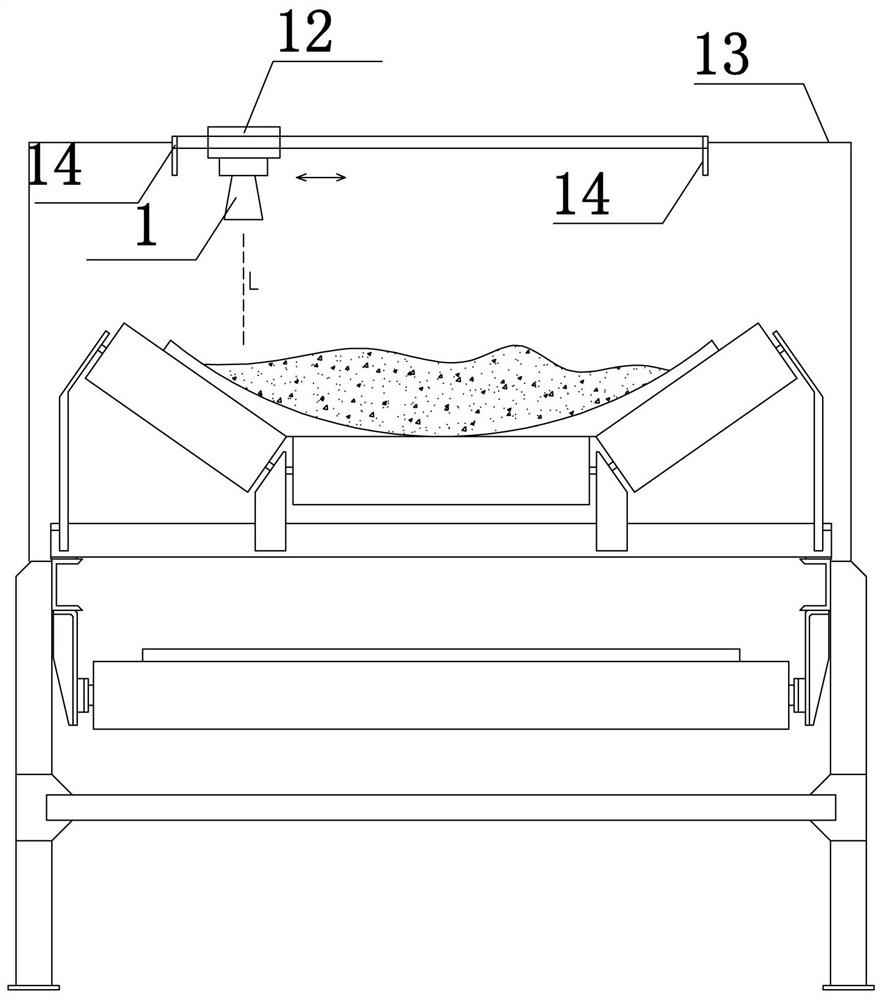

[0020] like Figure 1-5 As shown, the volume-based analysis of the present invention based on volumetric analysis, including the three belts provided in the three belts provided in each of the ball roller screen, respectively, in the three belts of the collapse, large ball, and the spheres, respectively. The positioning bracket 13 is disposed on the reciprocating operation of each material bracket 13, which is disposed on the stage meter 1 on each of the traveling clouds 12, and the mask connected to each stage 1. The cable, the computer system 2 connected to this shield cable, the host computer system 3 connected to this computer system 2, the computer system 2 includes a signal isolator 2-1, a DC power supply 2-4, an IO module 2- 2 and Computers 2-3, the host computer system 3 includes a software simulation analysis model.

[0021] The level meter 1 is a high-precision level measurement of radar, ultrasonic or laser form.

[0022] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com