A cooling roller device for wire drawing tractor and its using method and application

A cooling roller and tractor technology, which is applied in the directions of stretch spinning, textile and paper making, rayon filament physical therapy, etc., can solve the problems affecting the quality of fiber filament/film products, etc., and achieves simple structure, convenient use, and increased cooling. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

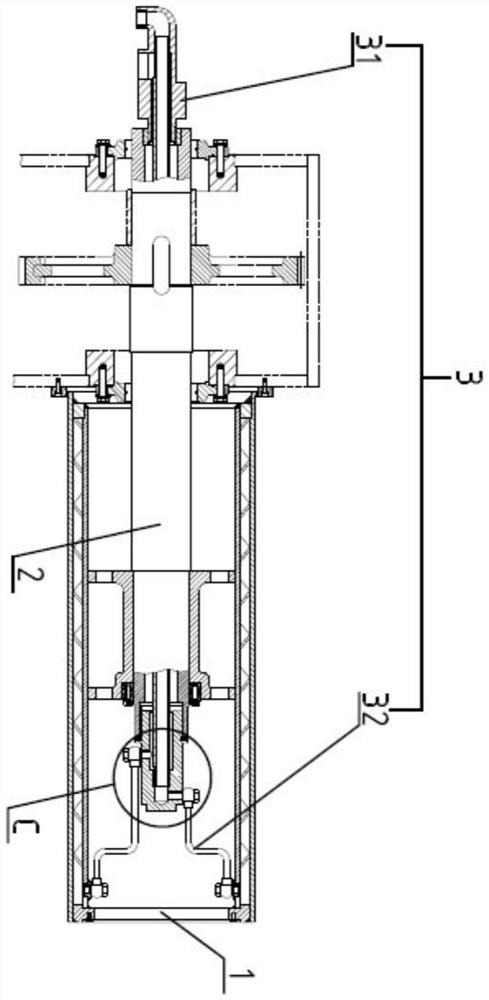

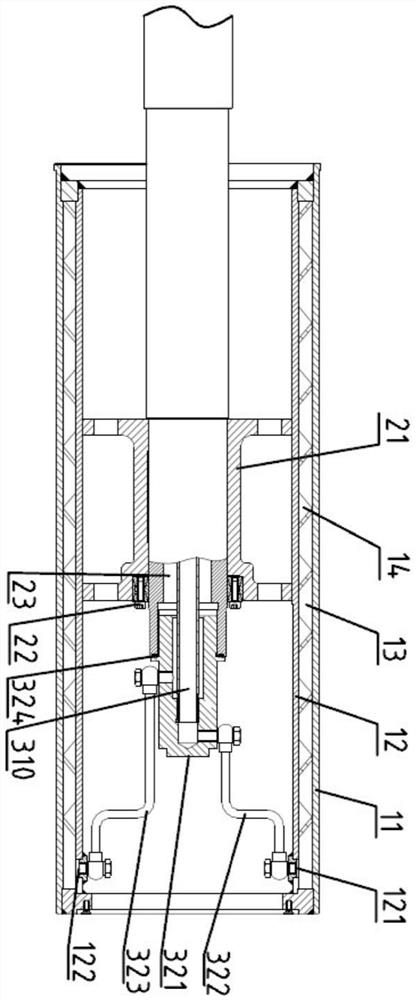

[0057] like Figure 1-6Shown a kind of cooling roller device for wire drawing tractor, comprises cooling roller 1, is connected with cooling roller 1 and is used for the cooling roller shaft 2 that transfers rotational torque to cooling roller 1, and described cooling roller 2 is sleeved on cooling roller 2. Inside the roller 1 , the cooling roller 1 includes an outer roller body 11 and an inner roller body 12 coaxially sleeved inside the outer roller body 11 , and a cooling roller fixedly connected to the inner roller body 12 is arranged inside the cooling roller 1 The shaft base 21, the cooling roller shaft base 21 and the cooling roller shaft 2 are fixedly connected by the expansion sleeve 22; it also includes a water circulation pipeline system 3 connected with the cooling roller 1 and the cooling roller 2;

[0058] An annular cooling water flow chamber 13 is formed between the outer roller body 11 and the inner roller body 12 , and the cooling water only flows inside the ...

Embodiment 2

[0074] The same parts of this embodiment and Embodiment 1 will not be repeated, and the differences are:

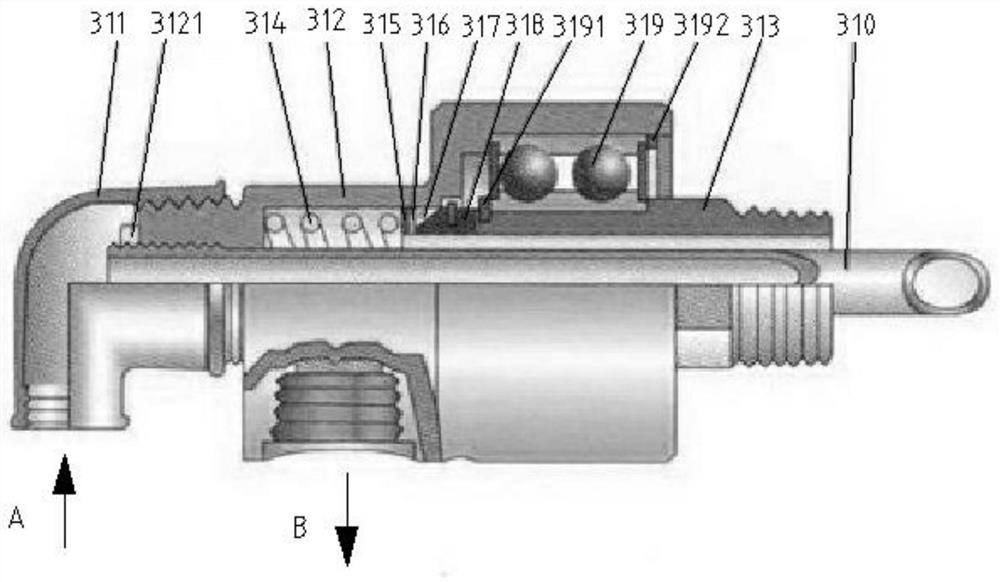

[0075] like Figure 7 As shown, through the elbow 311, the shell 312, the hollow shaft 313 and the inner tube 310 of the cooling roller 2 in sequence, it is divided into a first inner tube 3101 and a second inner tube 3102, the first inner tube 3101 and the elbow The water inlet A and the water inlet pipe assembly 322 communicate with each other, and the second inner pipe 3102 communicates with the elbow water outlet B and the water outlet pipe assembly 323 .

[0076] The cooling water flows into the first inner pipe 3101 through the elbow water inlet A, and flows into the cooling roller 1 through the water inlet pipe assembly 322. After heat exchange, it flows into the second inner pipe 3102 through the water outlet pipe assembly 323, and flows out through the elbow water outlet B .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com