Master-slave visual remote control system and method for mechanized workover workover operation

A control system and control method technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of inability to remote monitoring and remote control, high labor costs, inconvenient operation, etc., to ensure safe operation and The effect of construction quality and enhanced safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

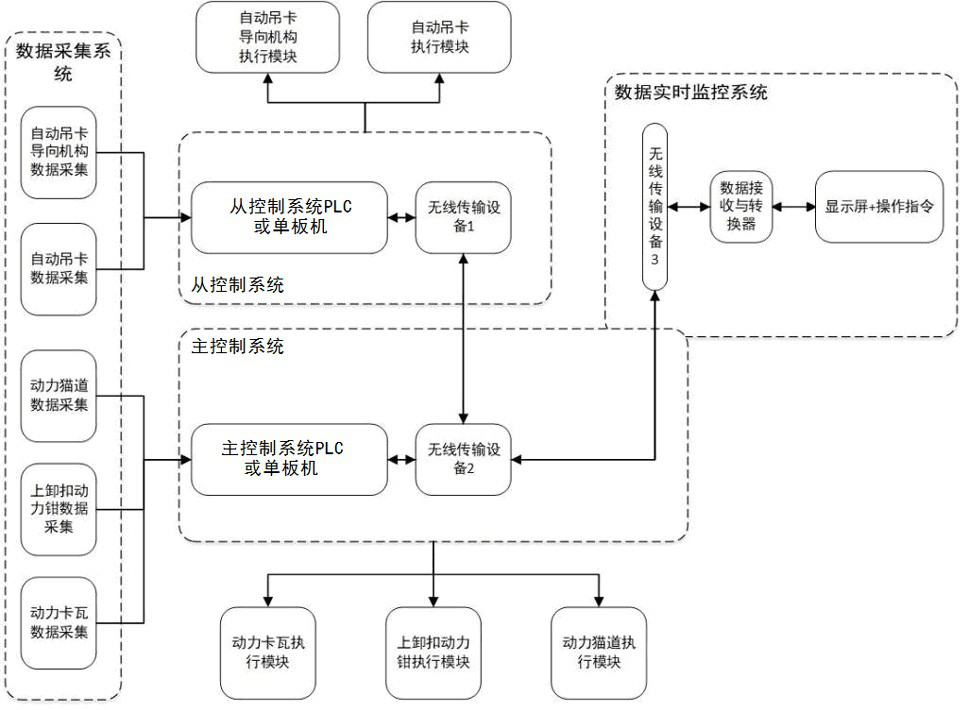

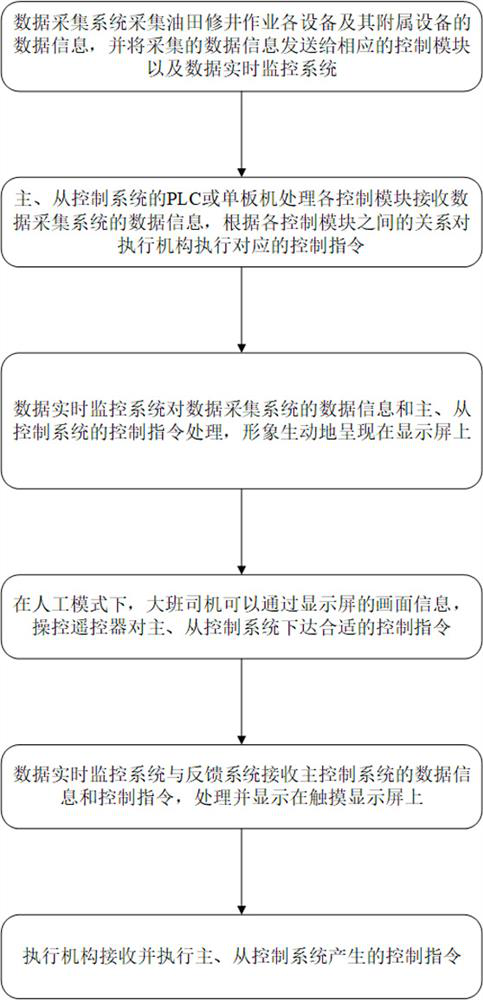

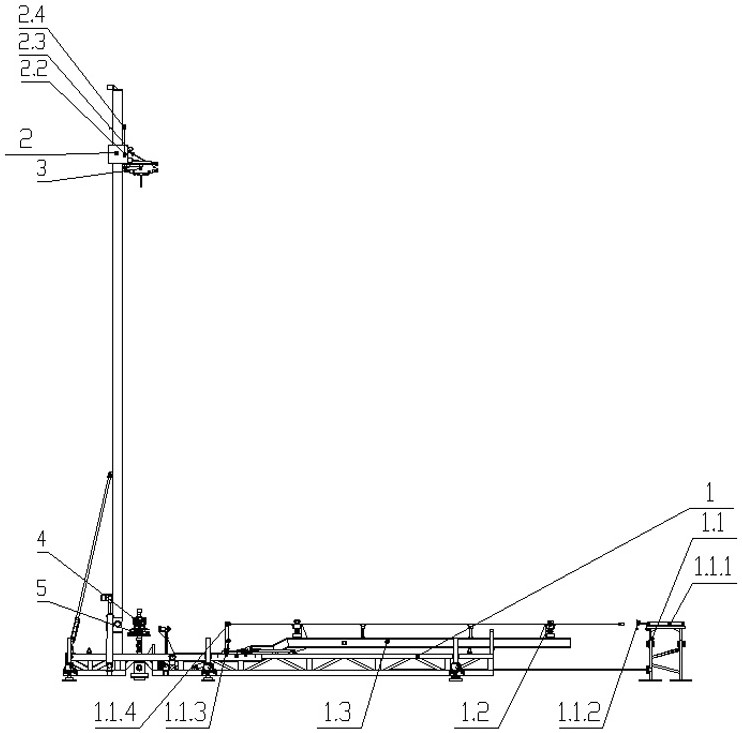

[0042] Embodiment 1, with reference to figure 1 , figure 2 , image 3 , a master-slave type visual remote control minor repair mechanized workover operation control system mentioned in the present invention includes a master control system, a slave control system, a data acquisition system, a real-time data monitoring system and an actuator. The transmission equipment is connected with the main control system. There can be multiple slave control systems. The core control components of the master and slave control systems are PLCs. -4AD-8DA; the model used by the slave control system PLC6.1 is CX3G-24MT), the overall function / performance of the master control system PLC is higher than that of the slave control system PLC6.1; the master control system PLC and wireless transmission equipment - radio frequency communication module 6.3 connected, located in the main control box, directly connected with the power catwalk data acquisition, make-up and breakout power tong data acq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com