Series connection module for photovoltaic cell layer and its preparation method and application

A photovoltaic cell and module technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve problems such as weak ability to withstand external forces at the edge of the battery, time consumed, huge energy, and reduced packaging efficiency of components, etc., to reduce the degree of stress , save input costs, reduce working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings and embodiments. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

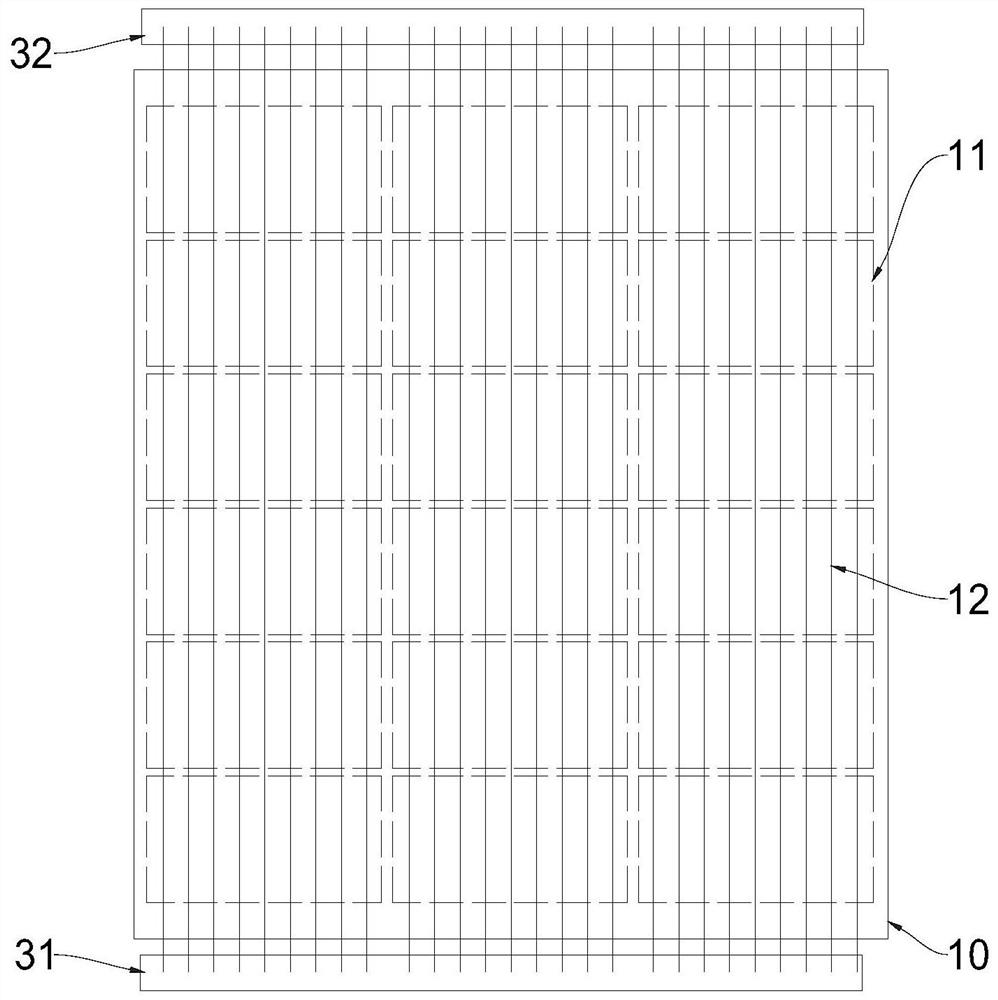

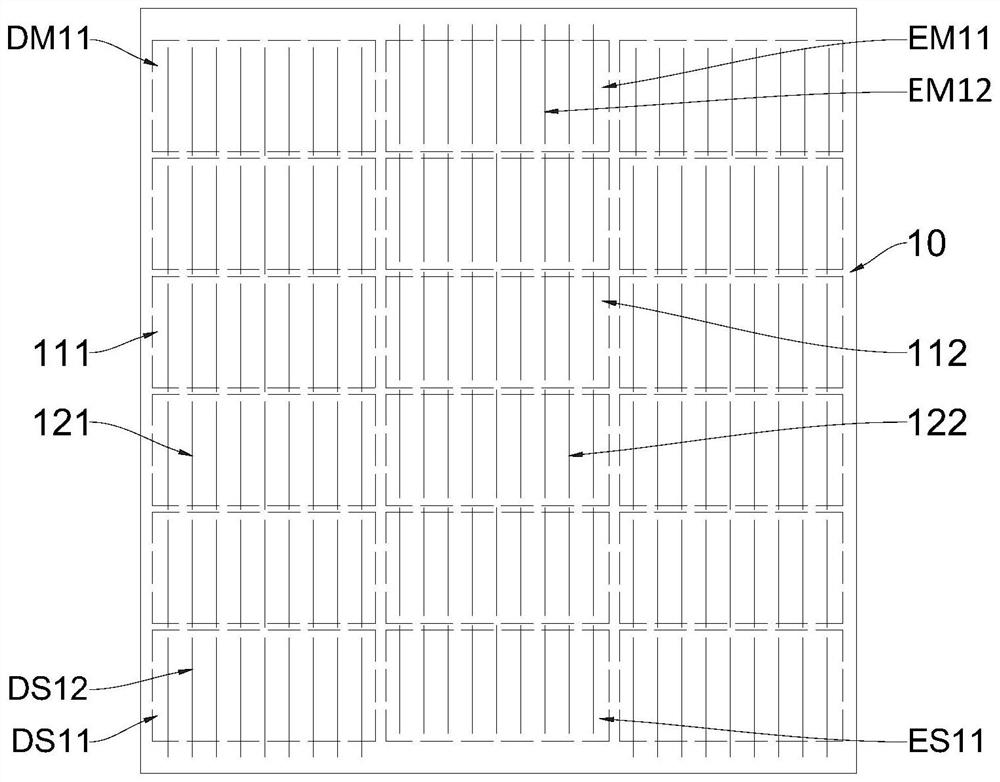

[0031] The present invention provides a method for preparing a series-connected component for a photovoltaic cell layer, which includes a preparation step of a first lay-up layer and a preparation step of a second lay-up layer, and the details are as follows.

[0032] A) The preparation steps of the first layup, including:

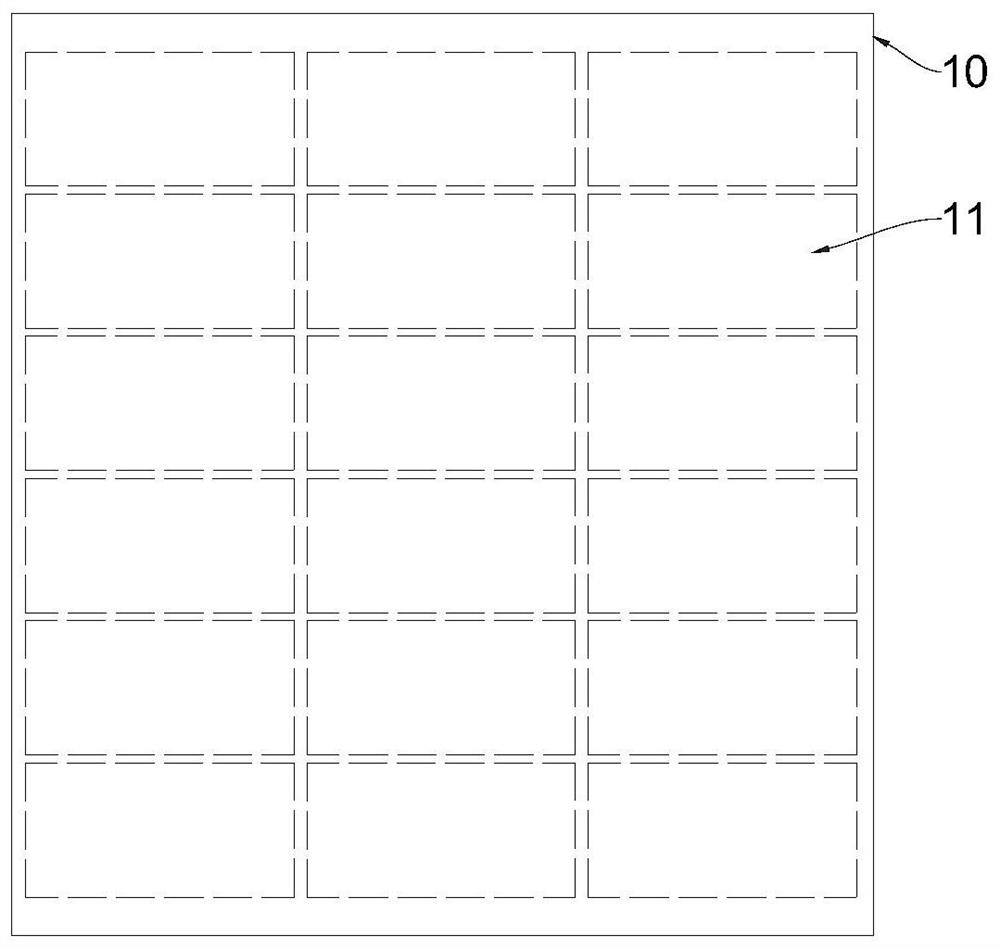

[0033] A1) as figure 1 As shown, the first transparent insulating film 10 is tiled; a plurality of placement areas 11 distributed in a rectangular array are divided on the top surface of the first transparent insulating film 10, so that the placement areas 11 in the same row are equally spaced along the left-right direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com