Steel sheet

A steel plate and plate thickness technology, applied in the field of steel plates, can solve problems such as cracks in solder joints, decreased strength of welded joints, and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

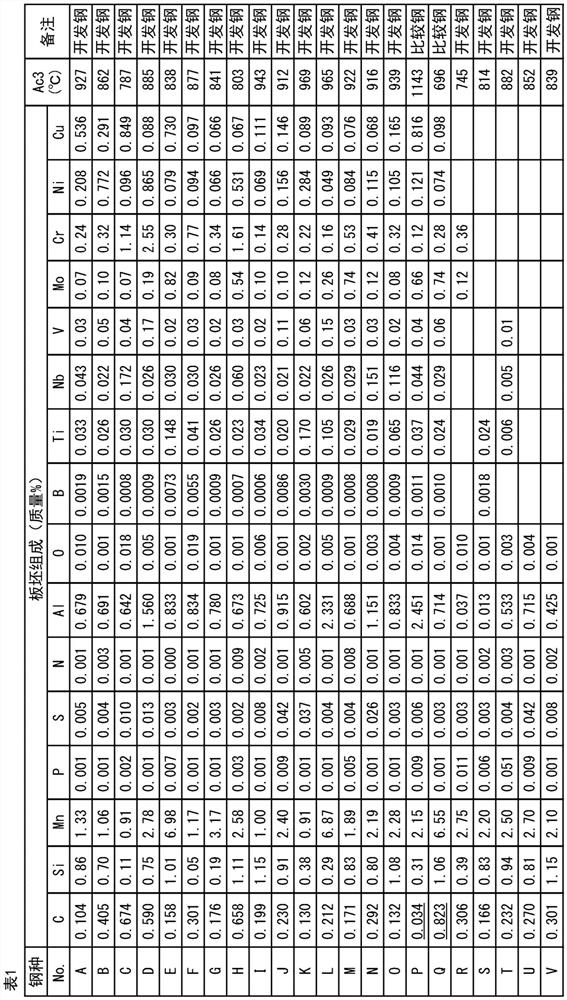

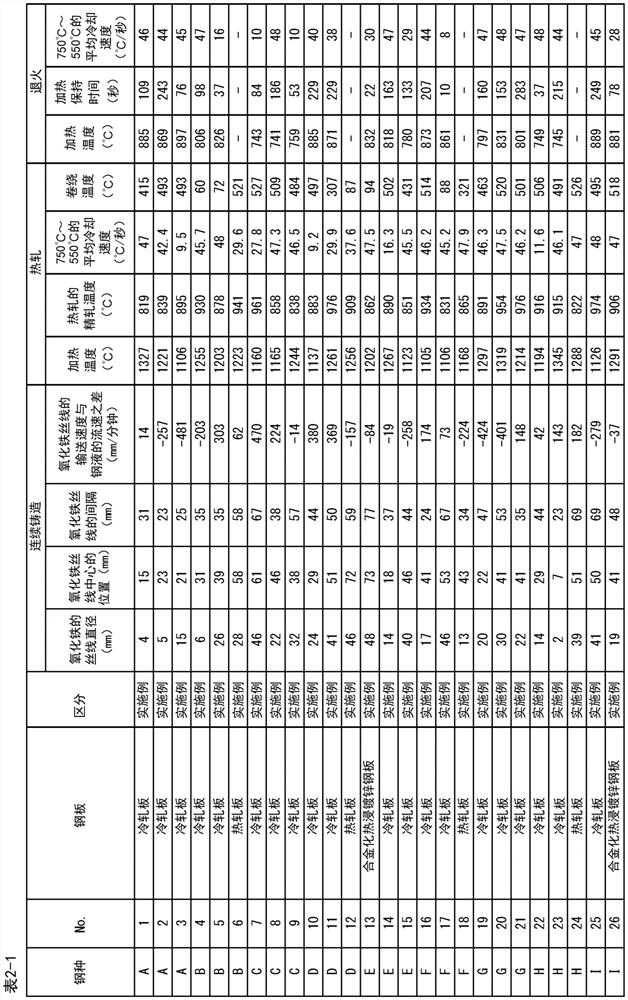

[0104] In the process of manufacturing a continuous casting slab having a thick cast slab having a thickness of 250 mm shown in Table 1, a wire-shaped iron oxide is added in accordance with the conditions shown in Tables 2-1 to 2-3 to obtain partial cloth in the surface layer. A slab with Al oxide. Tables 4-1 to 4-3 are shown: as the "position of the surface layer", is a wire-shaped iron oxide addition of wire-shaped iron oxide in the single surface portion to add a wire-shaped iron oxide. The slab is supplied to heat rolled under the conditions of the heating temperature, fine rolling temperature, and the winding temperature of the winding temperature, to obtain a hot rolled steel sheet. For steel sheets to be made into cold rolled steel sheets, after the hot rolled steel sheet is obtained as described above, the acid washing, the pressure reduction rate is 50% cold rolled, under the conditions shown in Tables 2-1 ~ 2-3. Annealing. Further, a portion of the steel sheet is carried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com