Steel sheet

A technology of steel plate and plate thickness, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as reduced weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

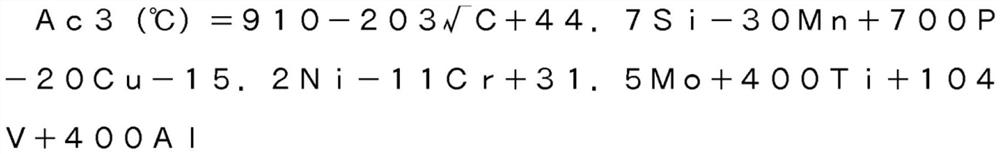

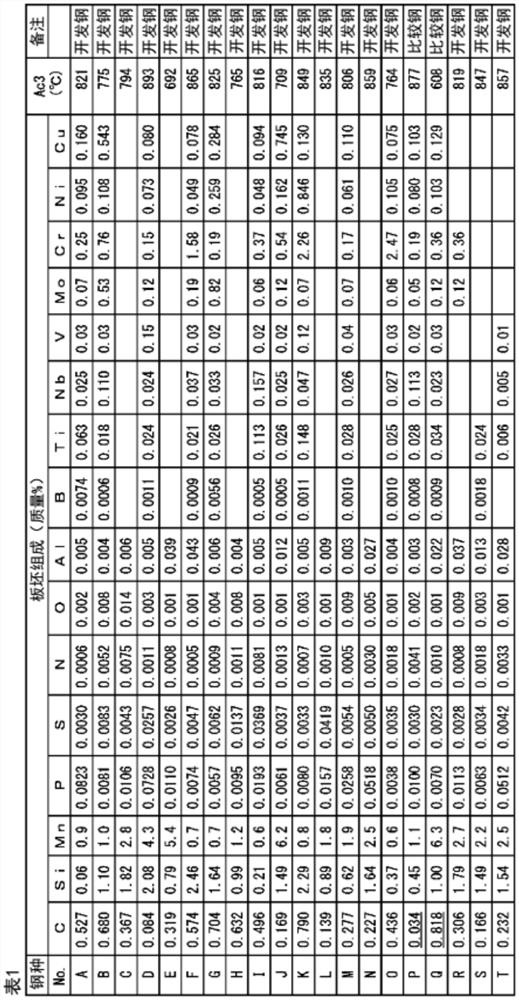

[0092]In the process of producing a continuously cast slab having a thickness of 250 mm having the chemical composition shown in Table 1, thread-like iron oxide was added under the conditions shown in Tables 2-1 to 2-3 to obtain A slab with Si oxides distributed in it. In Tables 4-1 to 4-3, those in which thread-like iron oxide was added to the surface layer on one side or those in which thread-like iron oxide was added to the surface layer on both sides were referred to as "positions of the surface layer". The slabs were subjected to hot rolling under the conditions of heating temperature, finish rolling temperature, and coiling temperature shown in Tables 2-1 to 2-3 to obtain hot-rolled steel sheets. For the steel sheet to be made into a cold-rolled steel sheet, after obtaining a hot-rolled steel sheet as described above, pickling and cold rolling with a total reduction ratio of 50% are carried out under the conditions shown in Tables 2-1 to 2-3. annealed. In addition, som...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com