Q/P phase cement clinker containing phosphorus calcium aluminate

A technology of cement clinker and calcium aluminum phosphate, applied in cement production, etc., can solve problems such as slow hydration and inability to meet the growth of cement strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

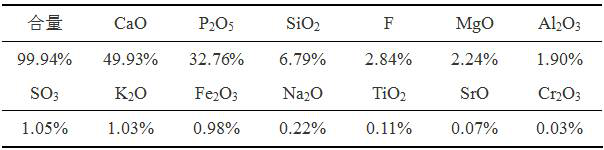

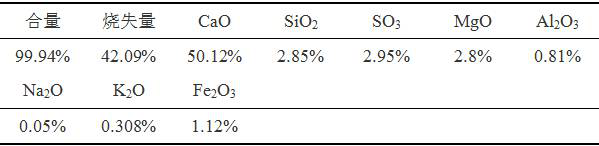

Method used

Image

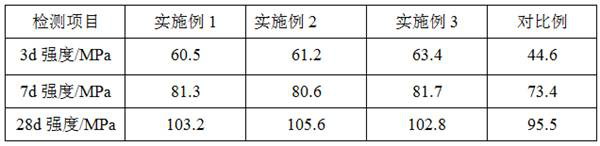

Examples

Embodiment 1

[0025] Calculate and weigh 200g of raw materials according to the mineral ratio, the particle size is to pass through a 200-mesh standard sieve, and the sieve residue is 6-10%. Then use a ball mill to stir, dry, and sample preparation. The sample is a circular cake-shaped sample with a diameter of 40 mm, which is dried in a low-temperature oven, then placed in a high-temperature calciner for firing at 1350 ° C, and kept for 2 hours.

[0026] The weight percentage of clinker mineral is:

[0027] Q / P phase: 40%

[0028] Calcium aluminophosphate: 35%

[0029] Calcium aluminate: 10%

[0030] Dicalcium silicate: 10%

[0031] Tetracalcium aluminoferrite: 5%.

Embodiment 2

[0033] Calculate and weigh 200g of raw materials according to the mineral ratio, the particle size is to pass through a 200-mesh standard sieve, and the sieve residue is 6-10%. Then use a ball mill to stir, dry, and sample preparation. The sample is a circular cake-shaped sample with a diameter of 40 mm, which is dried in a low-temperature oven, then placed in a high-temperature calciner for firing at 1350 ° C, and kept for 2 hours.

[0034] The weight percentage of clinker mineral is:

[0035] Q / P phase: 45%

[0036] Calcium aluminophosphate: 40%

[0037] Calcium aluminate: 10%

[0038] Dicalcium silicate: 3%

[0039] Tetracalcium aluminoferrite: 2%.

Embodiment 3

[0041] Calculate and weigh 200g of raw materials according to the mineral ratio, the particle size is to pass through a 200-mesh standard sieve, and the sieve residue is 6-10%. Then use a ball mill to stir, dry, and sample preparation. The sample is a circular cake-shaped sample with a diameter of 40 mm, which is dried in a low-temperature oven, then placed in a high-temperature calciner for firing at 1350 ° C, and kept for 2 hours.

[0042] The weight percentage of clinker mineral is:

[0043]Q / P phase: 50%

[0044] Calcium aluminophosphate: 35%

[0045] Calcium aluminate: 8%

[0046] Dicalcium silicate: 5%

[0047] Tetracalcium aluminoferrite: 2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com