High-reliability kiln for refractory material processing

A refractory and reliable technology, applied in the field of kilns, to achieve the effect of improving quality, increasing bearing capacity and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

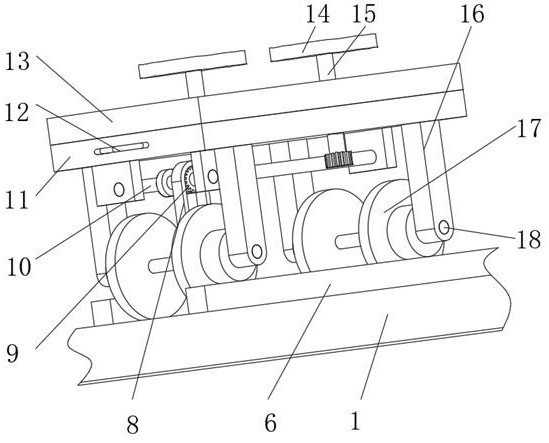

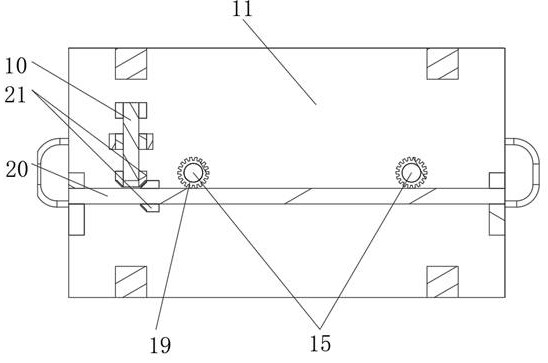

[0037] A high reliability kiln for refractory processing such as Figure 1-3As shown, it includes a track 6 arranged on the roadbed 1, and the top of the track 6 is matched with a transport vehicle assembly 4, and the transport vehicle assembly 4 includes a steel plate 11, at least two placement plates 14 and a wheel shaft 18, each of which The outer walls of the wheel shafts 18 are fixed with two rail wheels 17 by bolts, and the four rail wheels 17 are rollingly matched with the two rails 6 respectively. Bottom, the bottom of the steel plate 11 is rotatably connected with a transmission shaft 10, and the transmission shaft 10 and one of the axles 18 establish transmission cooperation with the synchronous belt 8 through the pulley 9, and the bottom of the steel plate 11 is rotatably connected with Worm screw one 20, described worm screw one 20 and transmission shaft one 10 establish transmission cooperation through a pair of bevel gears 21, the bottom of described placement pl...

Embodiment 2

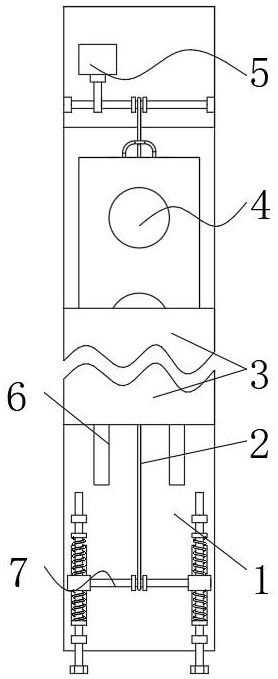

[0041] A high reliability kiln for refractory processing such as figure 1 As shown, in order to reduce the cost problem; this embodiment makes the following improvements on the basis of embodiment 1: it also includes a tunnel kiln main body 3 arranged on the top of the roadbed 1, and the inside of the tunnel kiln main body 3 is provided with an electric heater for heating The outer walls of the subgrade 1 located on both sides of the main body of the tunnel kiln 3 are respectively provided with a drive assembly 5 and a reversing tension assembly 7, and the outer walls of both sides of the steel plate 11 are welded with connecting buckles 12, and one of the connecting buckles 12. The drive assembly 5 , the reversing tension assembly 7 and the other connecting buckle 12 are connected through the twisted rope 2 in sequence.

[0042] When this embodiment is in use, since in embodiment 1, two groups of symmetrical driving assemblies 5 are respectively connected with the two sides o...

Embodiment 3

[0044] A high reliability kiln for refractory processing such as Figure 4-6 As shown, in order to solve the driving problem; this embodiment makes the following improvements on the basis of Embodiment 2: the drive assembly 5 includes a bevel gear 21 fixed on the roadbed 1 and a drive motor 26 fixed on the bevel gear 21 by bolts , the top of the bevel gear 21 is rotatably connected with transmission shaft three 22, and the outer walls of transmission shaft three 22 are respectively connected with reel 23 and worm gear two 24 through keys, and the outer wall of the output end of the drive motor 26 is connected by a coupling There is a worm two 25, and the two worms 25 and the two worm gears 24 mesh with each other. The reversing tension assembly 7 includes a fixed pulley 27 and a tension joint, and the inner wall of the fixed pulley 27 is connected with a drive shaft four 28 through a key, and the transmission Both ends of the shaft four 28 are rotatably connected with sliders ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com