Modified activated carbon fiber felt as well as preparation method and application thereof

A technology of activated carbon fiber felt and activated carbon fiber felt, which is applied in the field of modified activated carbon fiber felt and its preparation, can solve the problems of limited fogging agent, improve the sensory quality, increase the loading capacity of fogging agent, and generate high smoke gas Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

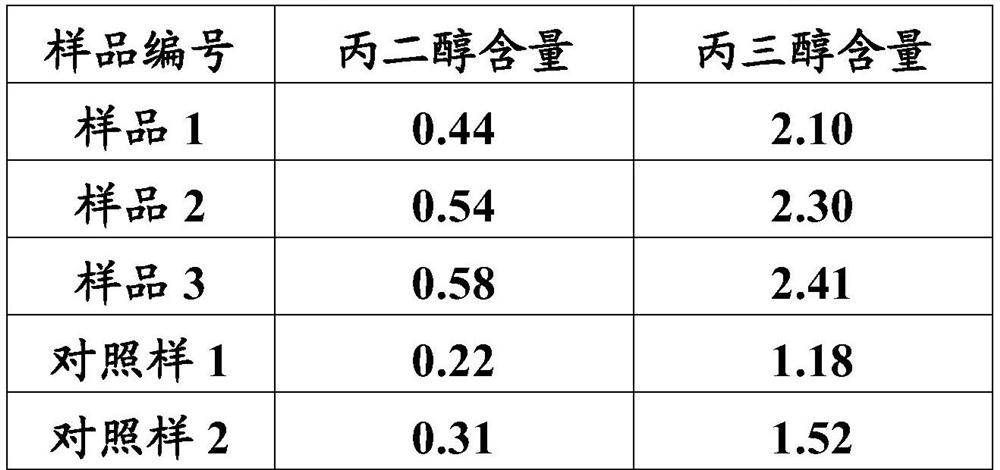

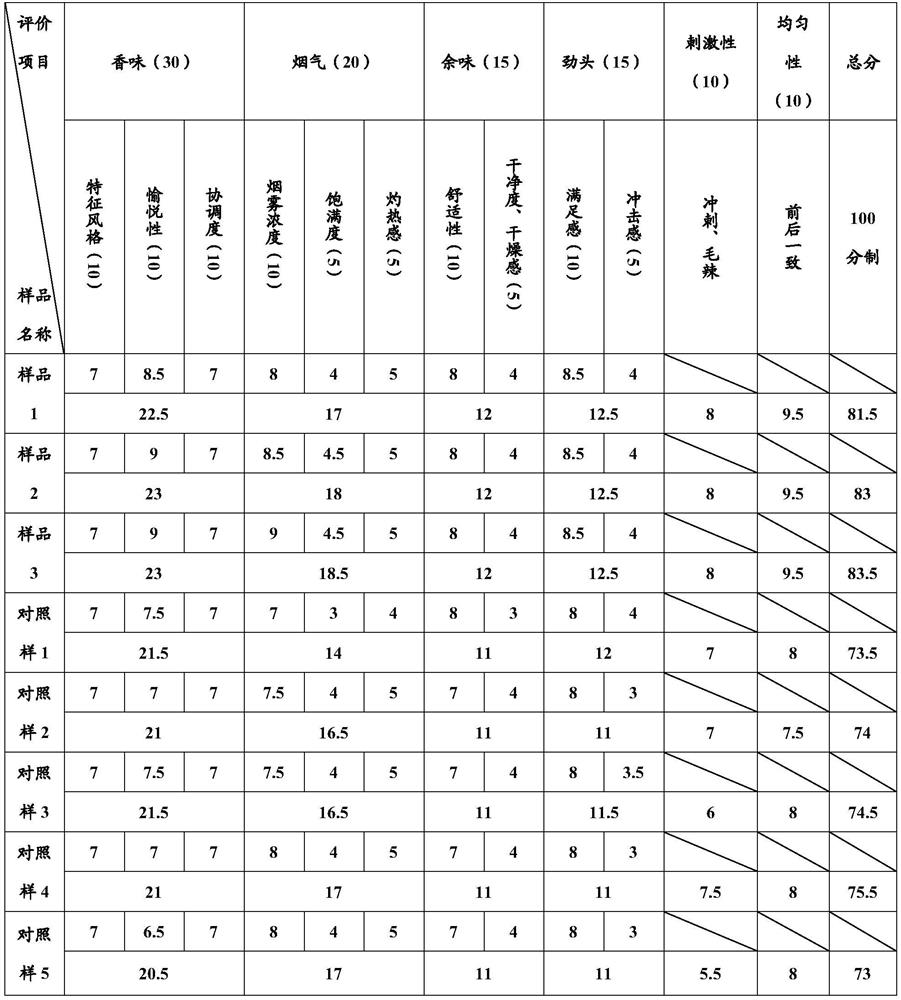

[0034] Example 1 Preparation of loaded activated carbon fiber felt as a heat-not-burn tobacco segment of aerosol carrier

[0035] Prepare 0.2M Mg(CH 3 COO) 2 Aqueous solution, 0.1M NaOH aqueous solution.

[0036] The specific surface area of activated carbon fiber felt is 1000m 2 / g, monofilament diameter is 20D, pore volume is 0.9cm 3 / g, the ash content is less than 1.5%, it is cut into 10cm×10cm, thickness 1mm for later use.

[0037] Keep glycerin on hand as a hair spray.

[0038] Dry the activated carbon fiber felt at 80°C for 24 hours for activation; take 10 g of the activated carbon fiber felt and soak it in 100 mL of Mg(CH 3 COO) 2 In the aqueous solution, NaOH solution was added dropwise under stirring conditions until the pH value was adjusted to 9, and the reaction was kept for 24 hours, and the activated carbon fiber felt after the reaction was washed with distilled water, and then dried in a vacuum oven at 90°C. The final activated carbon fiber felt is pla...

Embodiment 2

[0041] Example 2 Preparation of loaded activated carbon fiber felt as a heat-not-burn tobacco segment as a carrier of an aerosol

[0042] Prepare 0.3M Mg(CH 3 COO) 2 Aqueous solution, 0.1M NaOH aqueous solution.

[0043] The specific surface area of activated carbon fiber felt is 1500m 2 / g, monofilament diameter is 15D, pore volume is 1.0cm 3 / g, the ash content is less than 1.5%, it is cut into 10cm×10cm, thickness 2mm for later use.

[0044] Dry the activated carbon fiber felt at 80°C for 24 hours for activation; take 10 g of the activated carbon fiber felt and soak it in 100 mL of Mg(CH 3 COO) 2In the aqueous solution, add NaOH solution dropwise under stirring conditions until the pH value is adjusted to 9, keep it standing still for 24 hours, wash the activated carbon fiber felt after reaction with distilled water, and then dry it in a vacuum oven at 60°C. The final activated carbon fiber felt is placed in a heating furnace, heated to 350°C for 8 hours under the p...

Embodiment 3

[0047] Example 3 Preparation of loaded activated carbon fiber felt as a heat-not-burn tobacco segment of aerosol carrier

[0048] Prepare 0.4M Mg(CH 3 COO) 2 Aqueous solution, 0.1M NaOH aqueous solution.

[0049] The specific surface area of activated carbon fiber felt is 2000m 2 / g, monofilament diameter is 10D, pore volume is 1.5cm 3 / g, ash content is less than 1.5%, it is cut into 10cm * 10cm, thickness 5mm standby.

[0050] Dry the activated carbon fiber felt at 80°C for 24 hours for activation; take 10 g of the activated carbon fiber felt and soak it in 10 mL of Mg(CH 3 COO) 2 In the aqueous solution, NaOH solution was added dropwise under stirring conditions until the pH value was adjusted to 9, and the reaction was kept for 24 hours, and the activated carbon fiber felt after the reaction was washed with distilled water, and then dried in a vacuum oven at 80°C. The final activated carbon fiber felt is placed in a heating furnace, heated to 350°C for 6 hours unde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com