Efficient textile printing and dyeing wastewater treatment equipment

A technology for textile printing and dyeing and wastewater treatment, which is applied in filtration separation, separation methods, moving filter element filters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

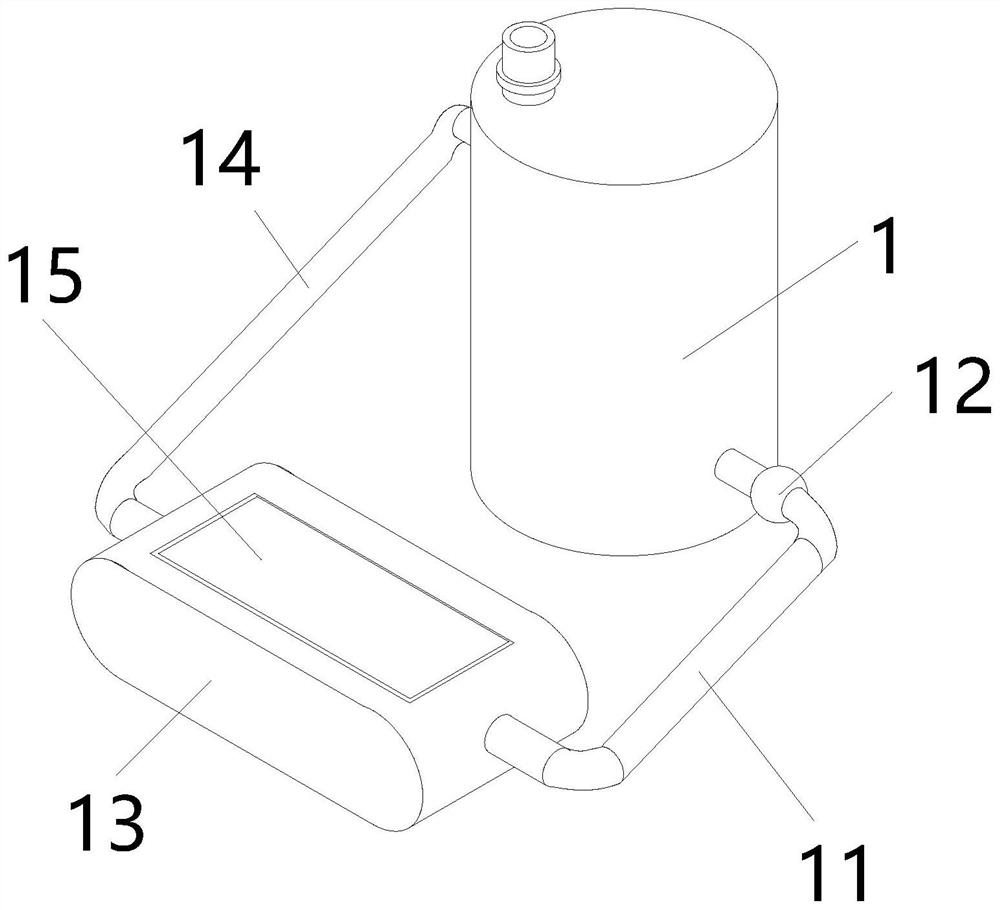

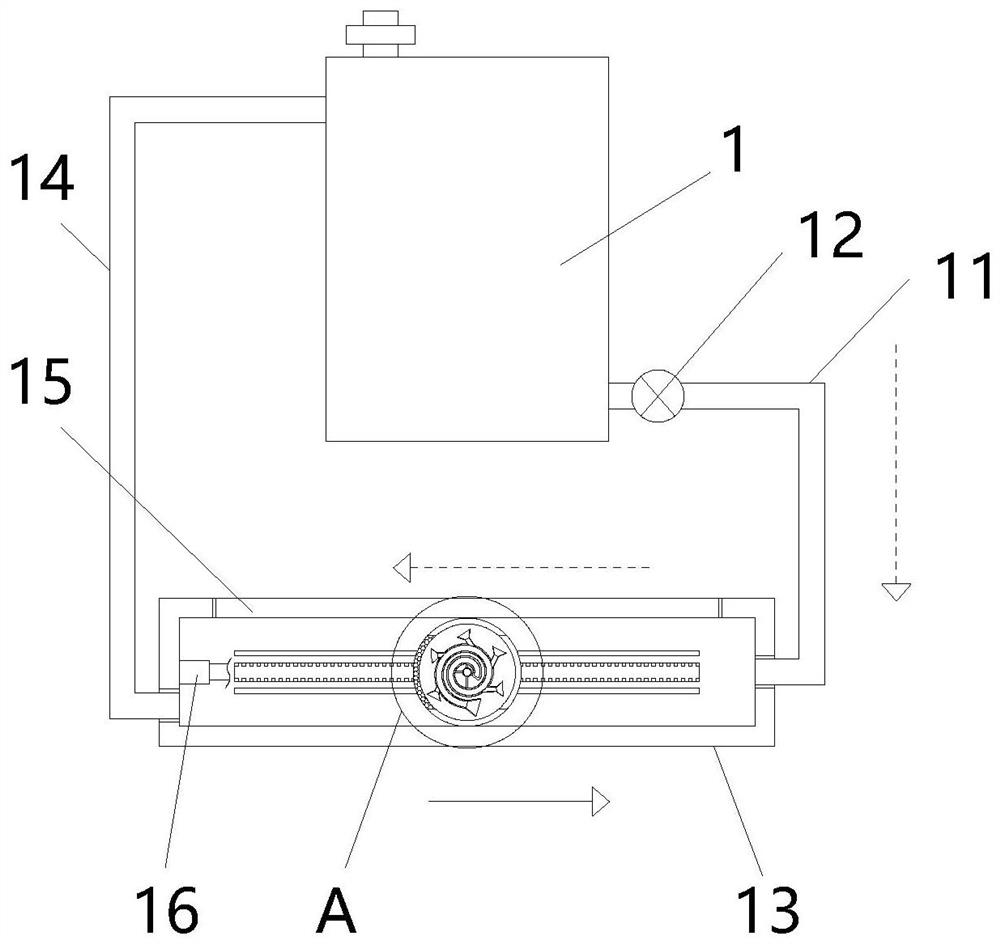

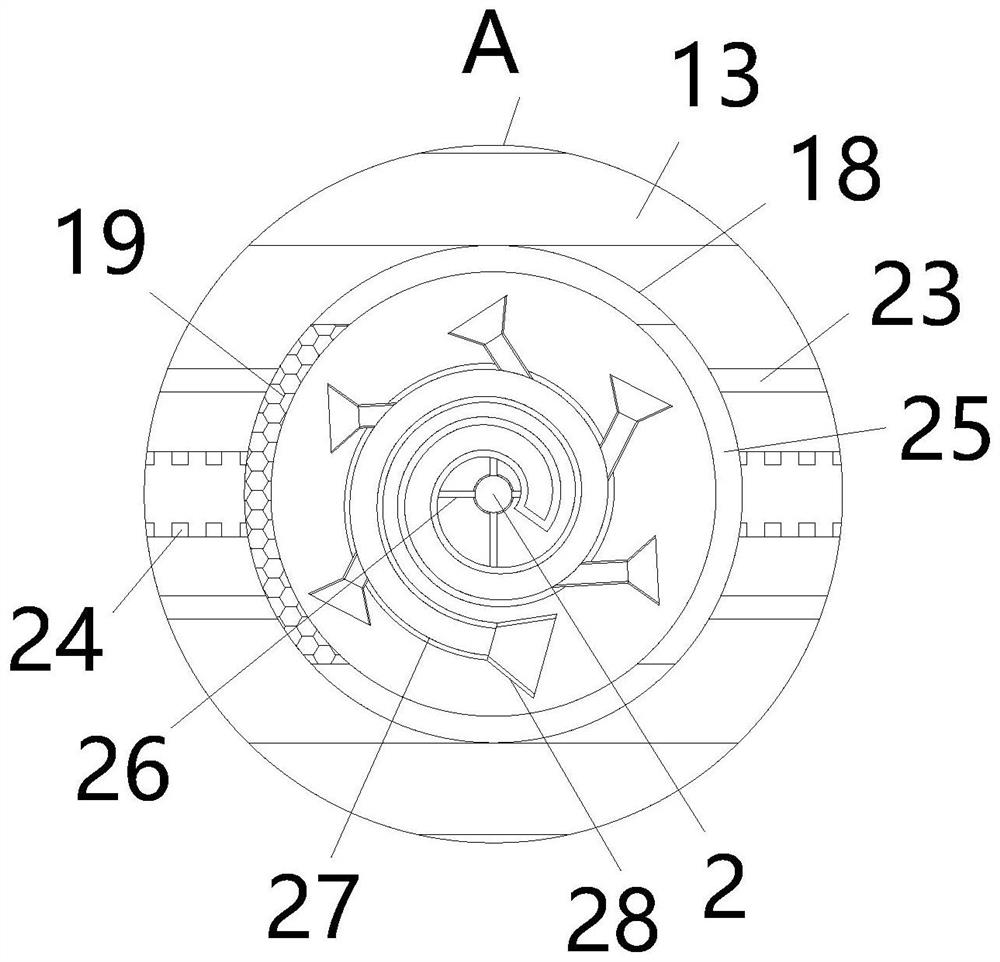

[0034] Embodiment: a kind of efficient textile printing and dyeing wastewater treatment equipment, such as figure 1 - Figure 7 Shown, comprise waste water tank 1 and treatment box 13, between the right side bottom outer wall of waste water tank 1 and the right side wall surface of treatment box 13, water inlet pipe 11 is fixedly installed, and water pump 12 is installed on water inlet pipe 11, and waste water tank 1 An outlet pipe 14 is fixedly installed between the left side top wall surface and the left side wall surface of the treatment box 13, the treatment box 13 is a hollow rectangular body with arc-shaped protrusions on both sides, and a sealed box cover is installed on the top of the treatment box 13 15. A hydraulic rod 16 horizontally facing the right side is fixedly installed in the left cavity of the processing box 13. A filtering device is arranged in the cavity of the processing box 13. The filtering device is composed of a guide column 17 and two filter cartridg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com