Preparation of COF-316/CAT-1 composite material and photocatalytic carbon dioxide reduction

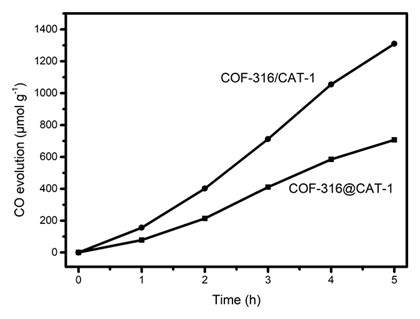

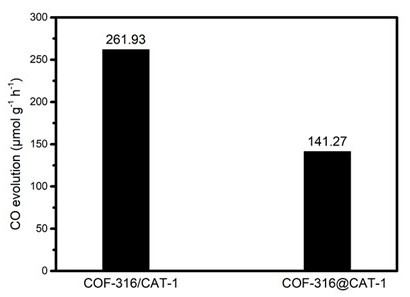

A technology of COF-316 and CAT-1, which is applied in the direction of carbon monoxide, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc., can solve the problem of low efficiency of photocatalytic carbon dioxide reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

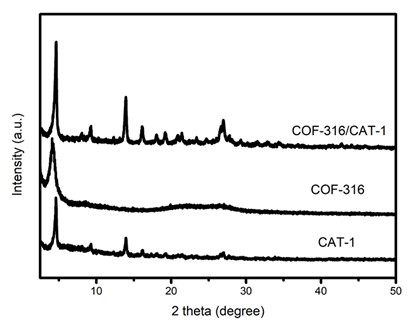

[0019] Example 1: The preparation of a COF-316 / CAT-1 composite material in this embodiment is completed according to the following steps:

[0020] 1. Preparation of COF-316: Add 15mg of 2,3,6,7,10,11-hexahydroxytriphenylenebenzene and 13.8mg of tetrafluoroterephthalonitrile into a Pyrex tube, and pour into the tube Add 1 mL of 1,4-dioxane and 39 μL of triethylamine, sonicate for 0.5 h, and perform four liquid nitrogen freezing-degassing operations, and place the degassed Pyrex tube in an air atmosphere to thaw naturally, and thaw Then put it in an oven at 150°C for reaction, turn off the oven after 84 hours, let it cool naturally, filter the product in the Pyrex tube, and wash with N,N-dimethylformamide, methanol and deionized water until the filtrate becomes colorless , dry naturally in the air for 30h to obtain COF-316 material;

[0021] 2. Preparation of COF-316-Ni: Add 10mg of COF-316 and 50mg of nickel acetate into a 50mL beaker in sequence, add 30mL of methanol for ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com