Integral casting prefabrication method for hollow beam slab

A hollow beam and bottom plate technology, used in manufacturing tools, ceramic molding mandrels, ceramic molding machines, etc., can solve the problems of long construction period and many processes, and achieve the effect of improving pouring efficiency and reducing processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The embodiment of the present application discloses a prefabrication method for hollow beam slabs, which includes the following steps:

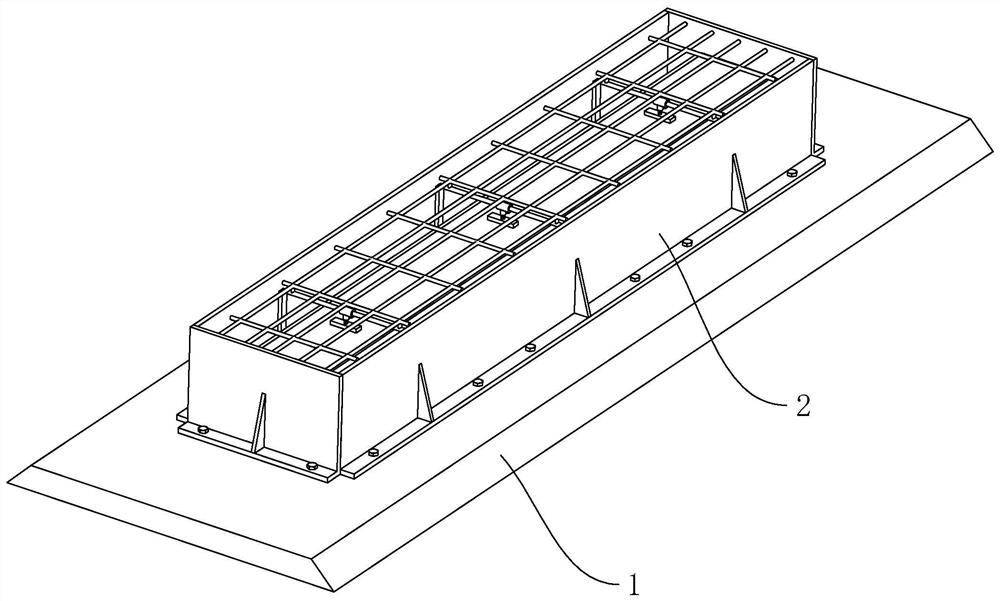

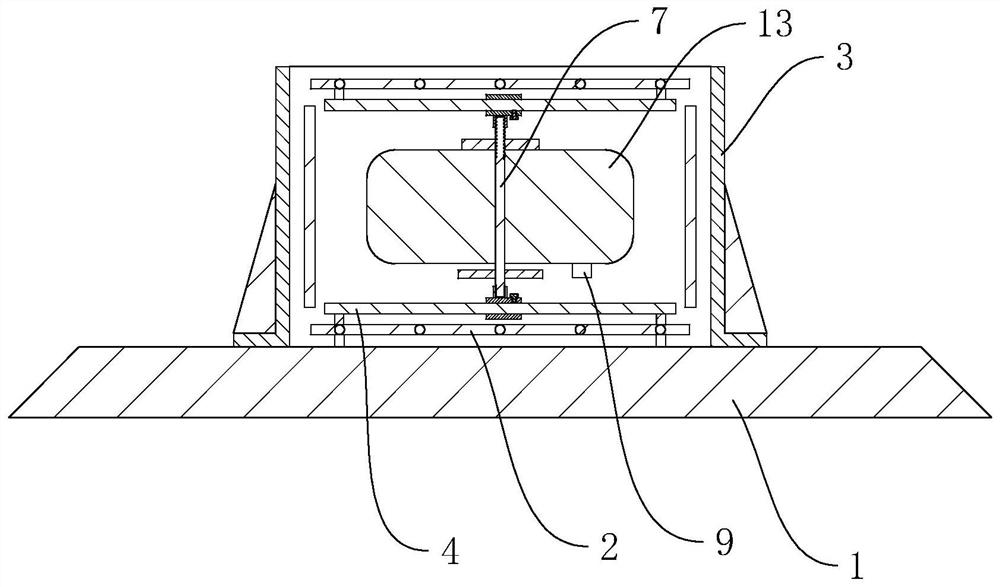

[0045] Step 1, refer to figure 1 and figure 2 , clean the base 1, the base 1 is a concrete mold in this embodiment, first wash and clean the dust and rust on the pedestal, and then apply a release agent on the base 1, generally 2 to 3 times, and apply Brush evenly to prevent the base 1 from sticking to the beam body, causing damage to the base 1.

[0046] Step 2: Fabricate and install the reinforcement frame of the bottom plate. 2. The grade and diameter of the reinforcement shall be manufactured in strict accordance with the requirements of the design documents. The reinforcement shall be connected by welding. The main reinforcement and other welded reinforcement shall be welded on both sides. Finally, install the bottom plate reinforcement frame 2 on the pedestal according to the design drawings.

[0047] Step 3, install formwork...

Embodiment 2

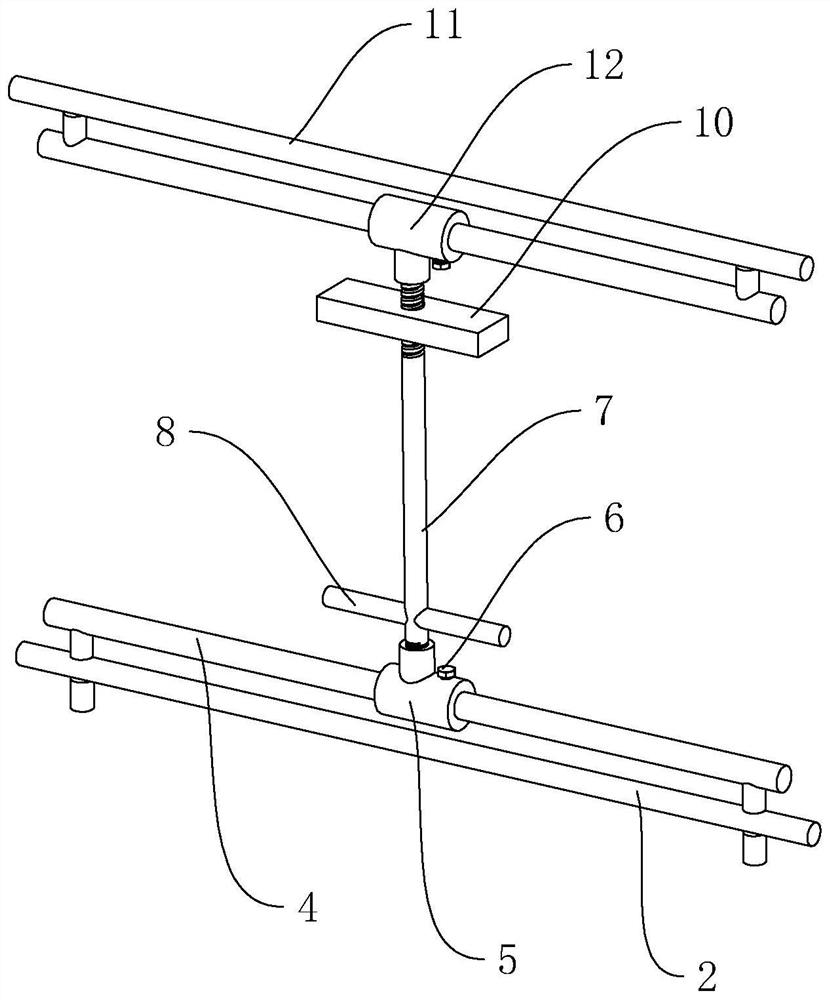

[0057] refer to Figure 4 and Figure 5 The difference between this embodiment and the first embodiment is that two sets of positioning rods 7 and mandrel positioning seats 5 are arranged along the width direction of the hollow beam slab, and the two positioning rods 7 are jointly installed at both ends of the same anti-floating plate 10 , the anti-floating plate 10 can slide along the axial direction of the positioning rod 7 . Locking nut 14 is threadedly connected on positioning bar 7, and anti-floating plate 10 is positioned between locking nut 14 and foam mandrel 13, and when screwing locking nut 14, locking nut 14 can be against the anti-floating plate 10 on On the foam mandrel 13. The corresponding top plate reinforcing bar frame 11 is also provided with two reinforcing bar positioning seats 12, and the reinforcing bar positioning seats 12 are plugged and matched with the positioning rods 7 one by one. By arranging two sets of positioning rods 7, the foam core mold 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com