Automatic feeding system for solid waste treatment

An automatic feeding and solid waste technology, applied in the direction of liquid treatment, conveyor objects, emptying containers, etc., can solve the problems of human health impact, physical health impact, labor intensity, etc., to avoid the impact of physical health, The effect of reducing work intensity and reducing contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

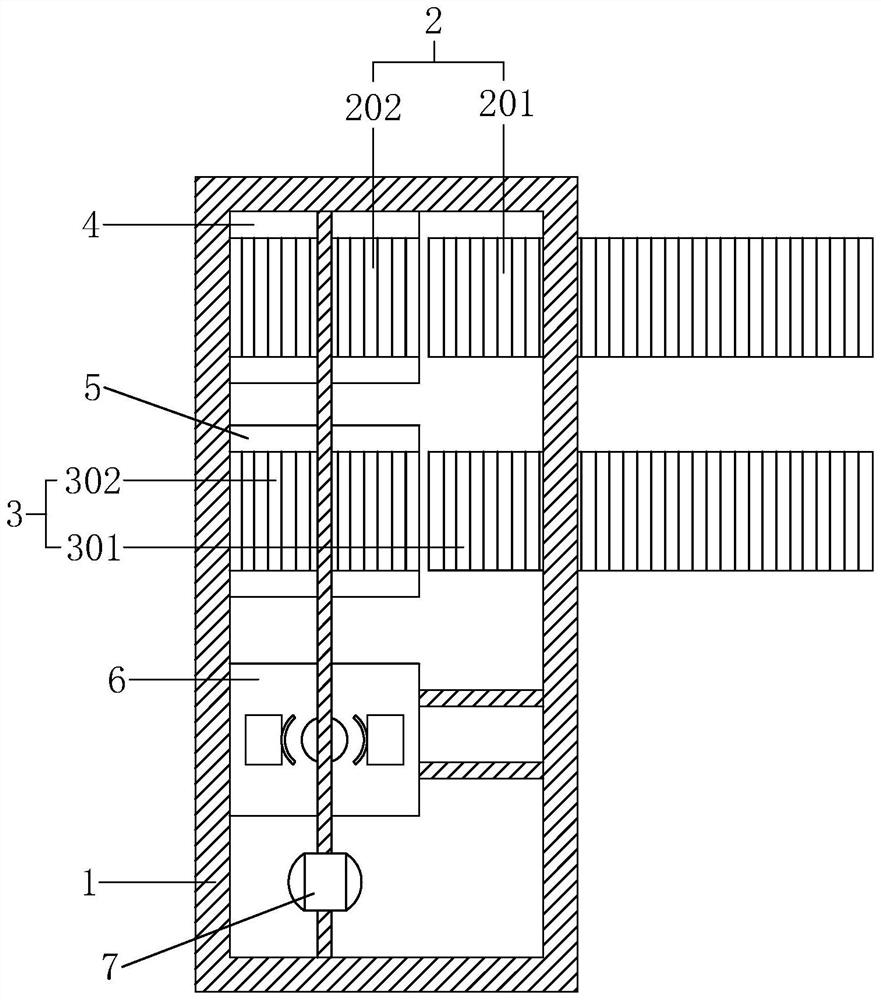

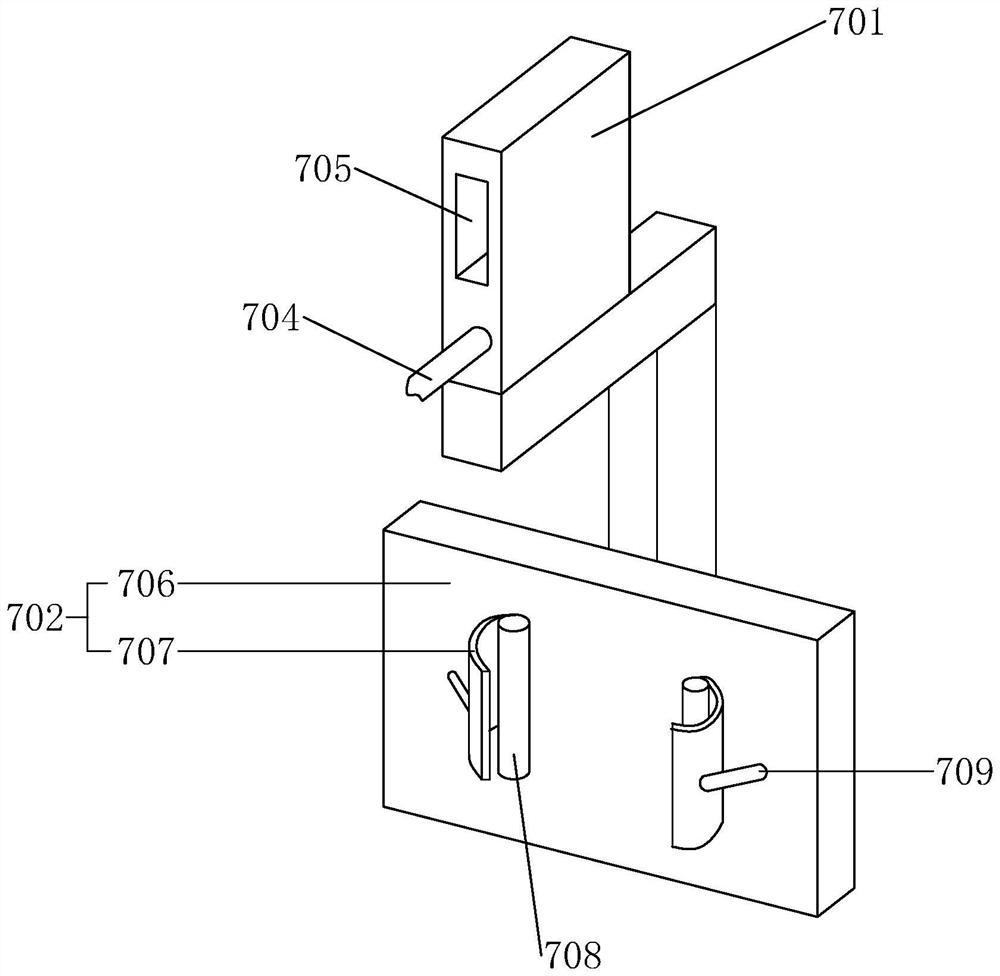

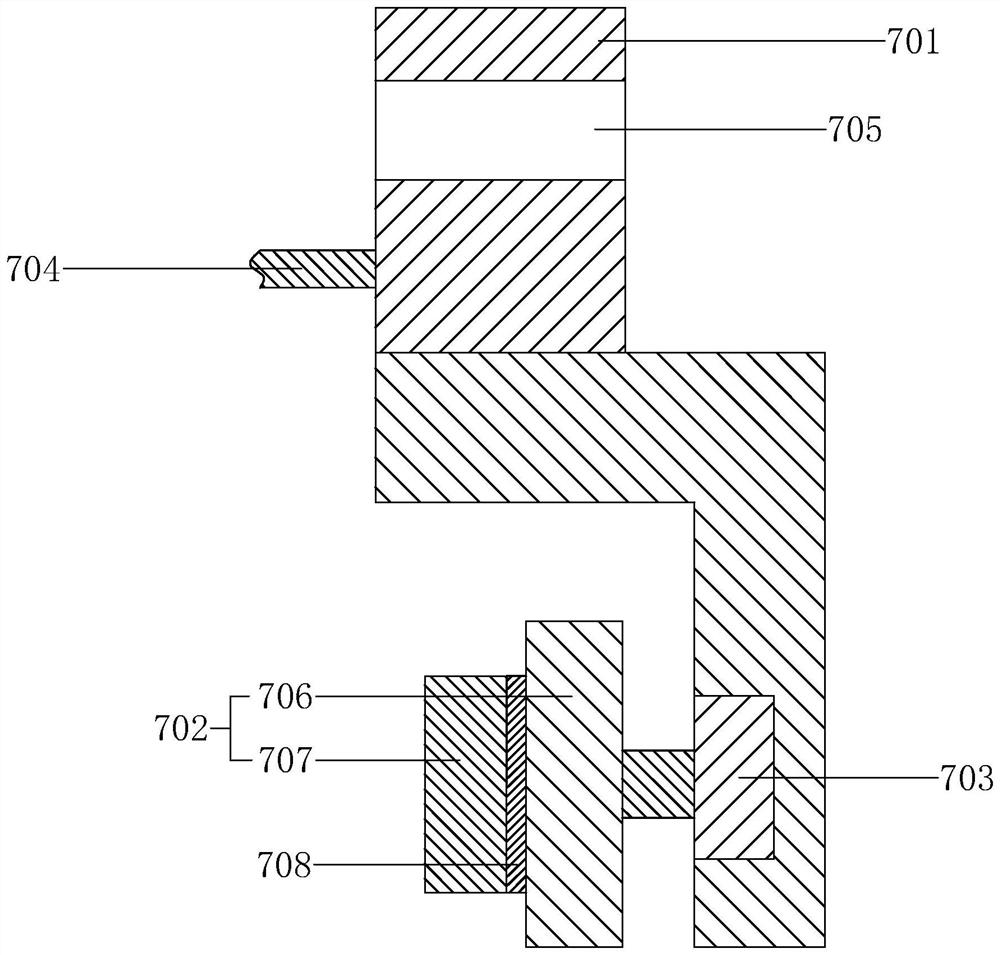

[0031]Embodiment 1: An automatic loading system for solid waste treatment, which is used for automatic loading of solid waste treatment devices, including an outer frame 1 and an internal engineering department. The outer frame 1 is welded by metal materials. The internal work section includes a first conveying section 2, a second conveying section 3, a first lifting section 4, a second lifting section 5, a vibrating unloading section 6 and a turning section 7.

[0032] The first transporter part 2 is used for transporting the barrels loaded with solid waste. The first conveyor section 2 includes a first front conveyor belt 201 and a first rear conveyor belt 202, the first front conveyor belt 201 and the first rear conveyor belt 202 are two separate conveyor belts, which have their own power outputs device, and they are all transported towards the position where the first lifter part 4 is located, the first rear conveyor belt 202 is located inside the first lifter part 4, the ...

Embodiment 2

[0041] Embodiment 2: Compared with Embodiment 1, the difference of Embodiment 2 is that: the hydraulic clamping device 702 includes a base 710 and two second jaws 711, and one end of the base 710 is fixedly connected to the output shaft of the turning cylinder 703, The other end of the base 710 is fixed with two second hydraulic cylinders 713 symmetrically arranged. The piston rods of the two second hydraulic cylinders 713 move in opposite directions, and the piston rods of the two second hydraulic cylinders 713 are fixed with fixed blocks. 712 , the two fixing blocks 712 are respectively fixedly connected with the two second jaws 711 .

[0042] When it is necessary to start the hydraulic clamping device 702 to clamp the barrel body, start the second hydraulic cylinder 713, the piston rods on the two second hydraulic cylinders 713 move toward each other, and drive the two fixed blocks 712 to move toward each other, thereby driving the two second hydraulic cylinders 713 to move ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com