Preparation method of nickel-based heterogeneous metal organic framework material and application of nickel-based heterogeneous metal organic framework material

A metal-organic framework and metal-based technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of high price, scarce storage capacity, and obstacles to wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

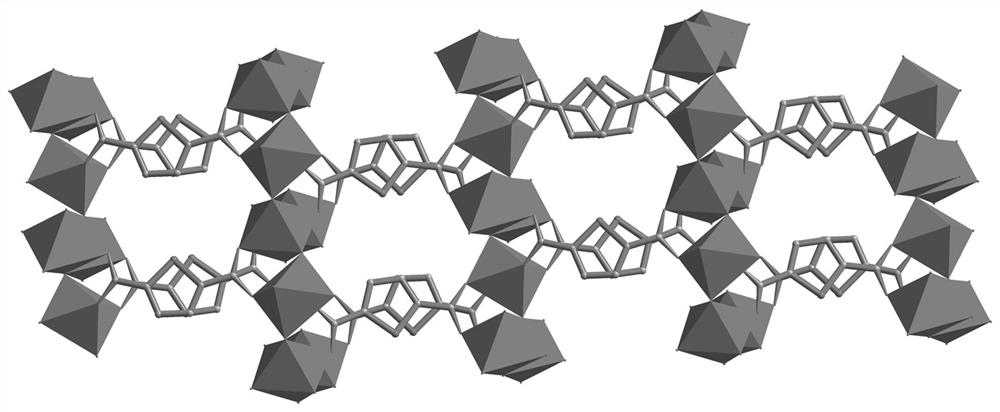

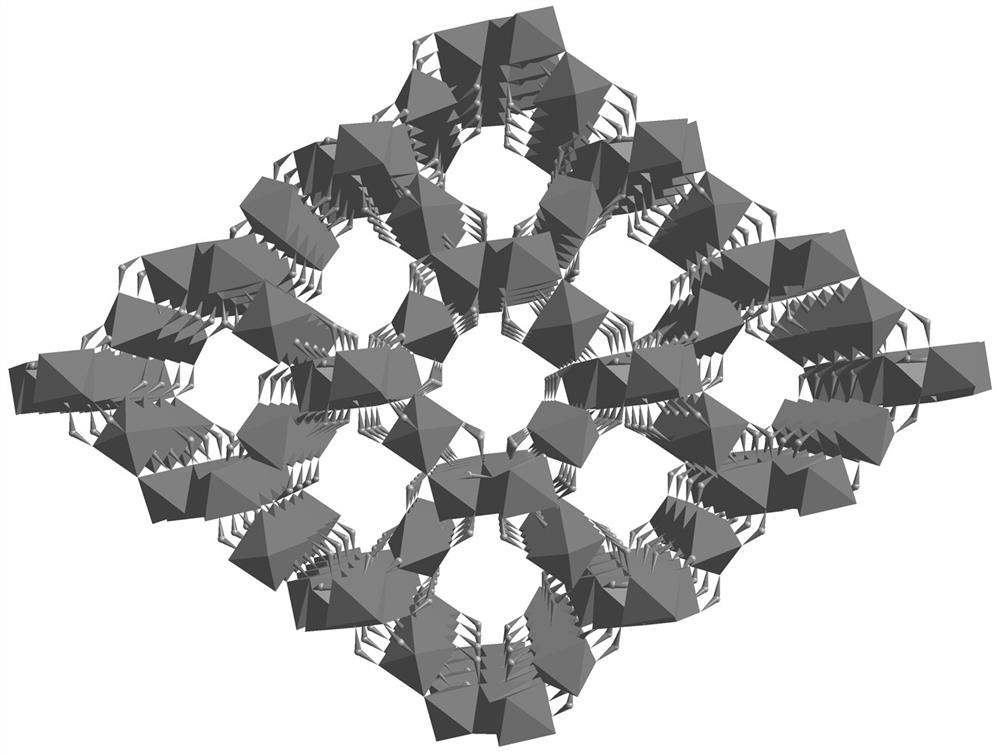

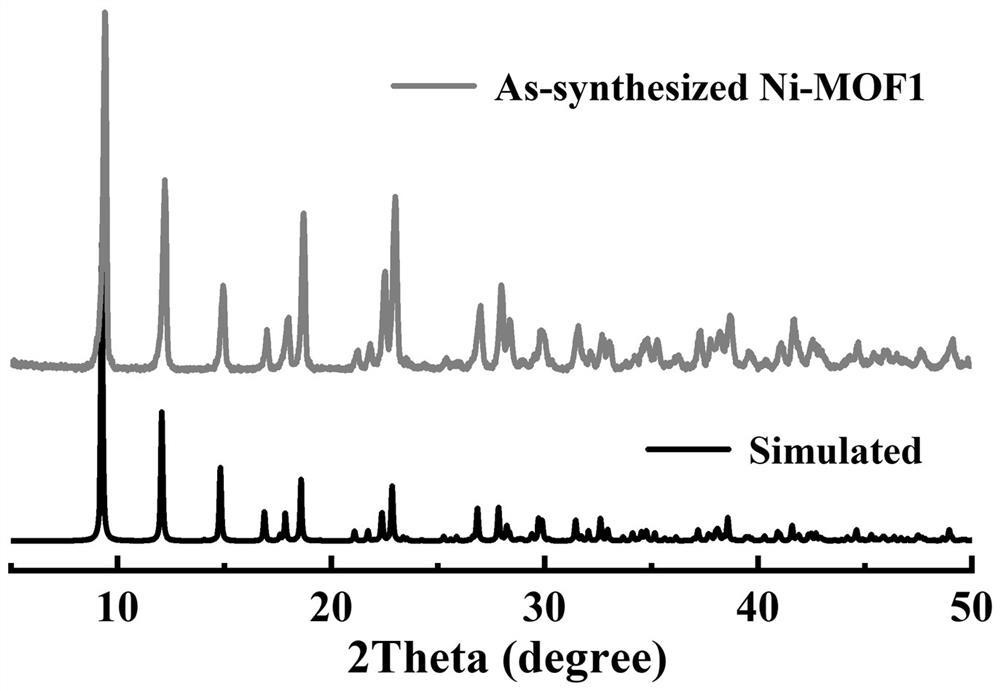

Image

Examples

Embodiment 1

[0025] Equally weigh 0.1mmol 2,5-thiophenedicarboxylic acid, 0.2mmol nickel sulfate, 2ml deionized water, 2ml N,N-dimethylacetamide (DMAC), respectively add to 10ml glass vials, and then add each 37% HBF was added to the vial with a mass concentration of 4 0ml-0.45ml (ie 0ml, 0.05ml, 0.1ml, 0.15ml, 0.2ml, 0.25ml, 0.3ml, 0.35ml, 0.4ml, 0.45ml), each reaction was sonicated for 30min and placed in a 120°C oven to keep the temperature After reacting for 36 hours, and cooling down to room temperature at a constant rate of 2-3°C / h, 10 glass vials gradually changed from turbid to clear liquid with the increase of acid content, and no crystals were produced.

Embodiment 2

[0027] Weigh 0.1mmol 2,5-thiophenedicarboxylic acid, 0.2mmol nickel sulfate, 2ml deionized water, and 2ml acetonitrile in equal amounts, add them to 10ml glass vials, and then add HBF with a mass concentration of 37% to each vial 4 0ml-0.45ml (ie 0ml, 0.05ml, 0.1ml, 0.15ml, 0.2ml, 0.25ml, 0.3ml, 0.35ml, 0.4ml, 0.45ml), each reaction was sonicated for 30min and placed in a 120°C oven to keep the temperature After reacting for 36 hours, and cooling down to room temperature at a constant rate of 2-3°C / h, all 10 glass vials were clear liquid, and no crystals were produced.

Embodiment 3

[0029] Weigh 0.1mmol 2,5-thiophenedicarboxylic acid, 0.2mmol nickel sulfate, 2ml deionized water, and 2ml ethanol in equal amounts, add them into 10ml glass vials, and then add HBF with a mass concentration of 37% in each vial 40ml-0.45ml (ie 0ml, 0.05ml, 0.1ml, 0.15ml, 0.2ml, 0.25ml, 0.3ml, 0.35ml, 0.4ml, 0.45ml), each reaction was sonicated for 30min and placed in a 120°C oven to keep the temperature After reacting for 36 hours, and cooling down to room temperature at a constant rate of 2-3°C / h, all the 10 glass vials were clear liquid, and no crystals were produced.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap