Graphite substrate and method for manufacturing same

A technology of graphite substrate and manufacturing method, which is applied in chemical instruments and methods, gaseous chemical plating, crystal growth, etc., can solve the problems of short wavelength at the edge of graphite substrate, increase the flow rate of MO source gas flow, and affect the distribution of Mo source gas, etc. Achieve the same luminous wavelength, improve the effect of excessive flow rate, and improve the uniformity in the chip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

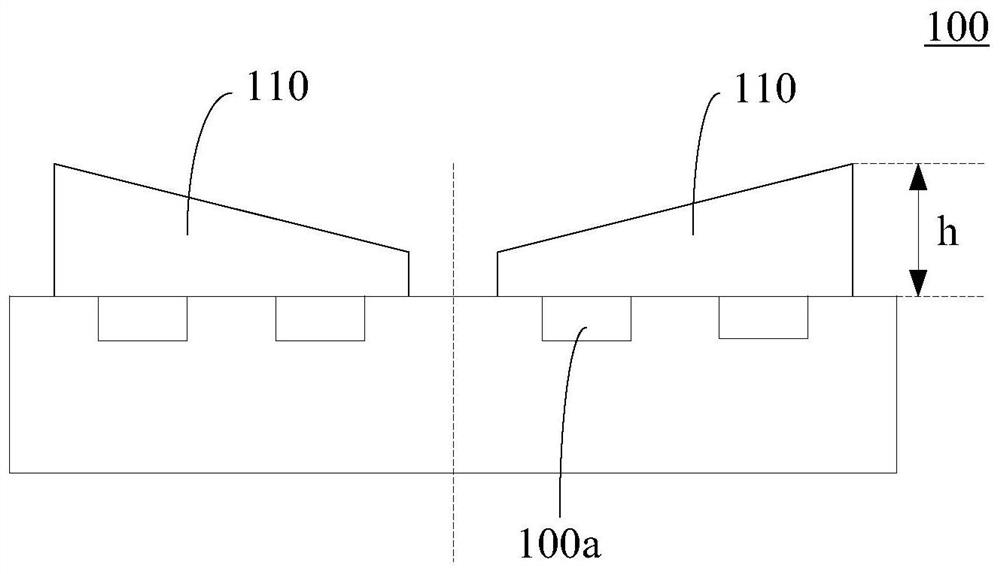

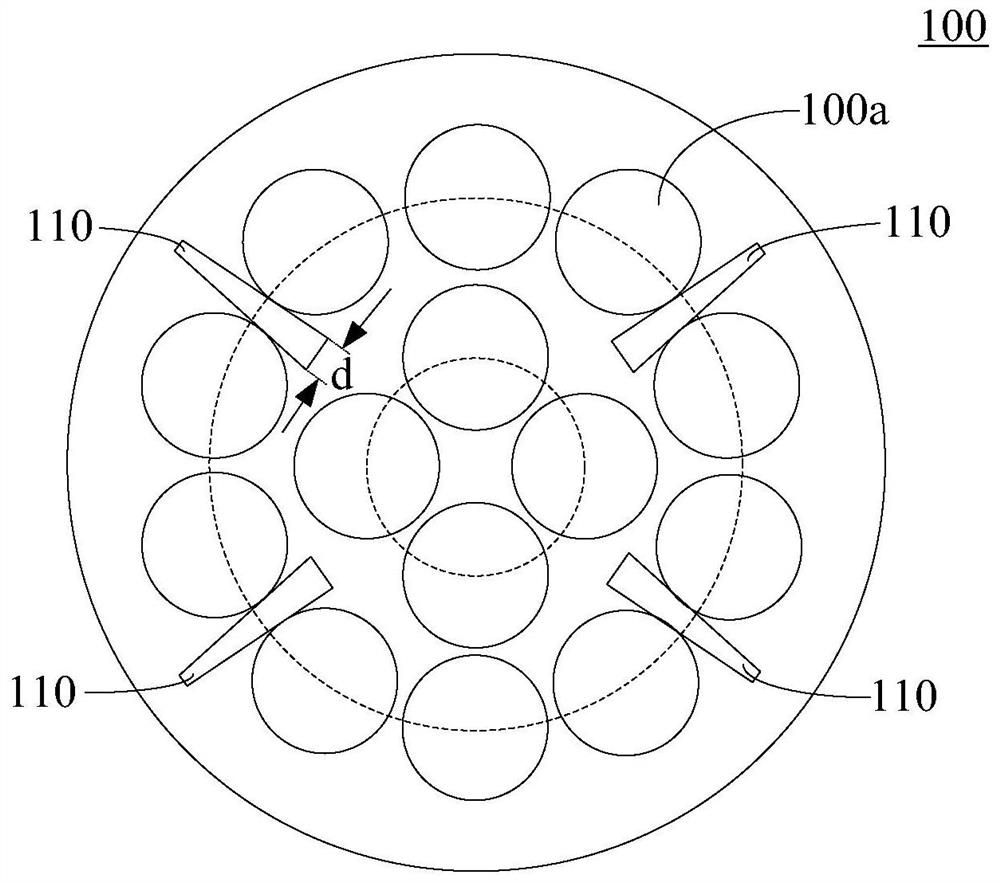

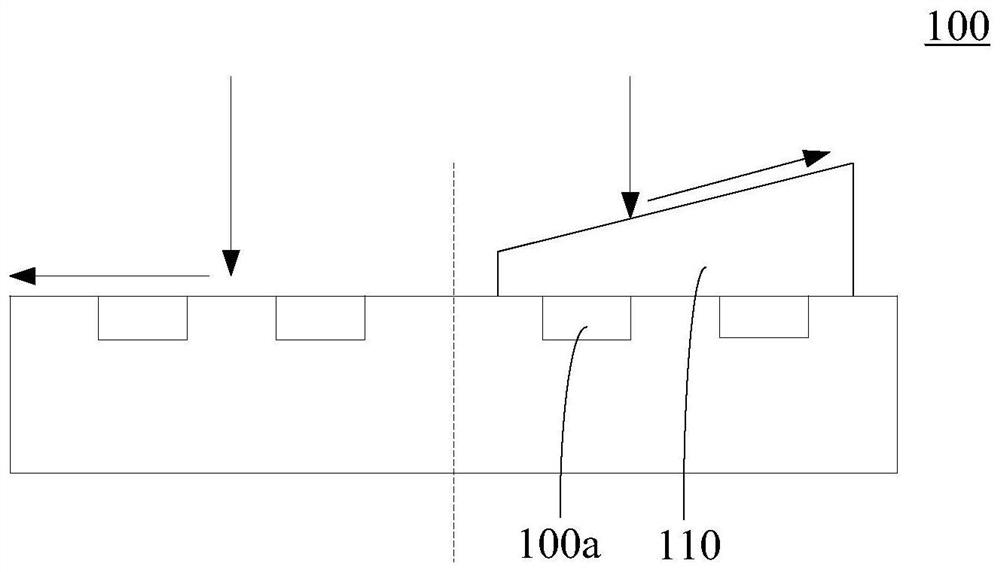

[0031] figure 1 is a front view of a graphite substrate provided by an embodiment of the present disclosure, figure 2 is a top view of a graphite substrate provided by an embodiment of the present disclosure, such as figure 1 and figure 2 As shown, the graphite substrate 100 is a disc, and the first surface of the graphite substrate 100 has multiple rings of grooves 100a for accommodating the substrate. The multiple rings of grooves 100 a are coaxial with the graphite substrate 100 , and each ring of grooves 100 a includes a plurality of grooves.

[0032] The graphite substrate 100 also includes a plurality of protruding structures 110 arranged on the first surface of the graphite substrate 100 in the radial direction of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com