Shock insulation groove system of novel house building foundation shock insulation structure

A technology for foundation isolation and new housing, which is applied in the direction of infrastructure engineering, building components, buildings, etc., and can solve the problems that affect the free movement and damage of the superstructure, the isolation trench cover plate and the isolation trench retaining wall cannot slide freely, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

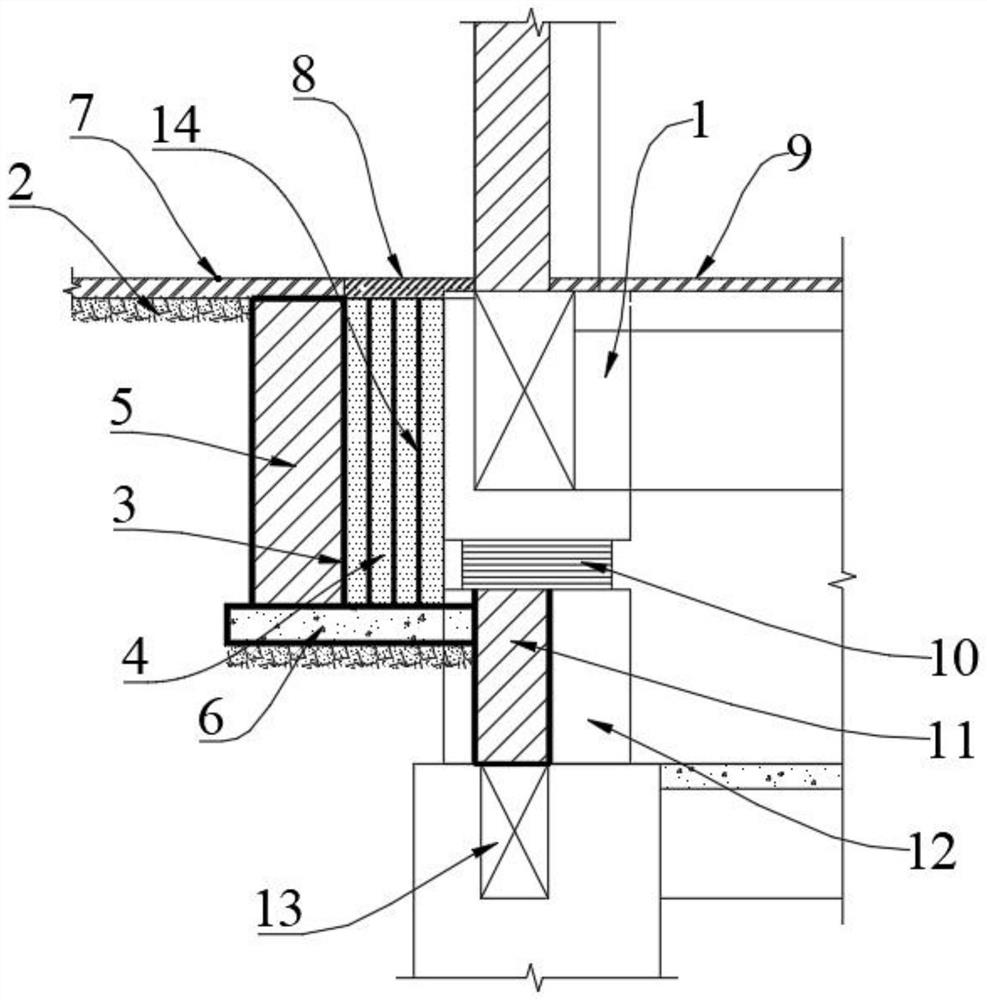

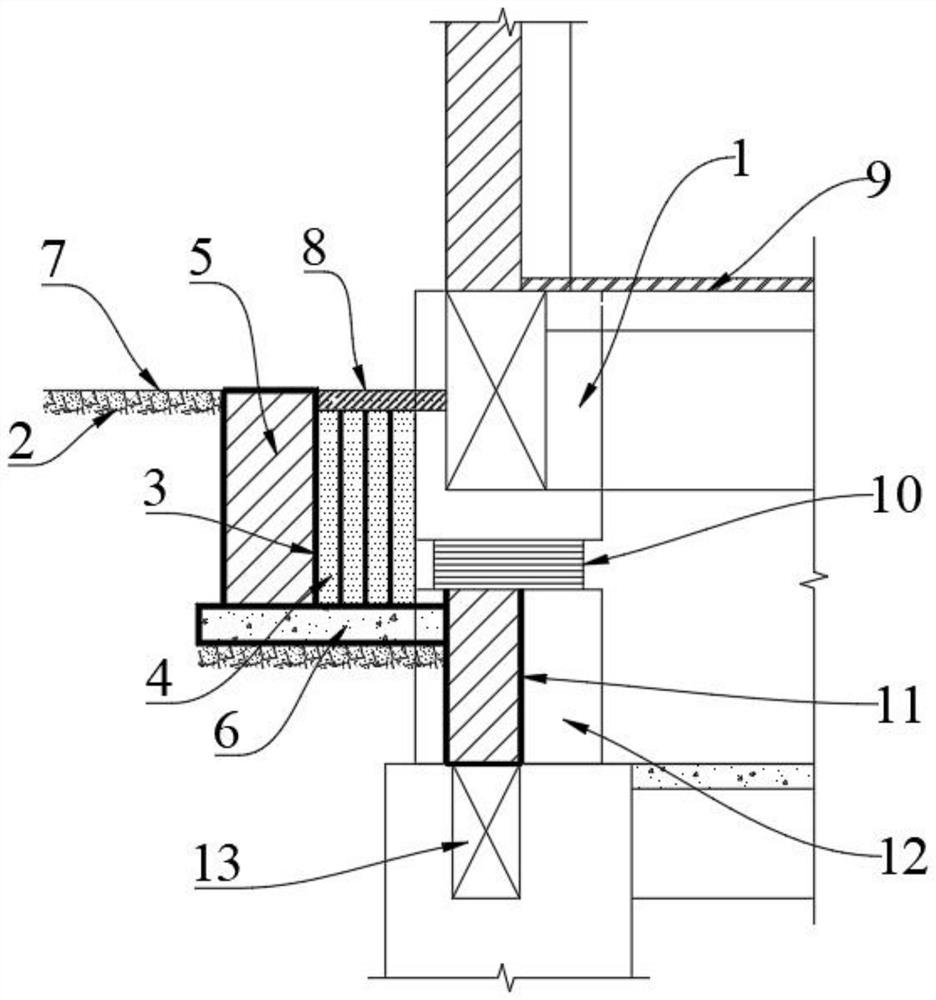

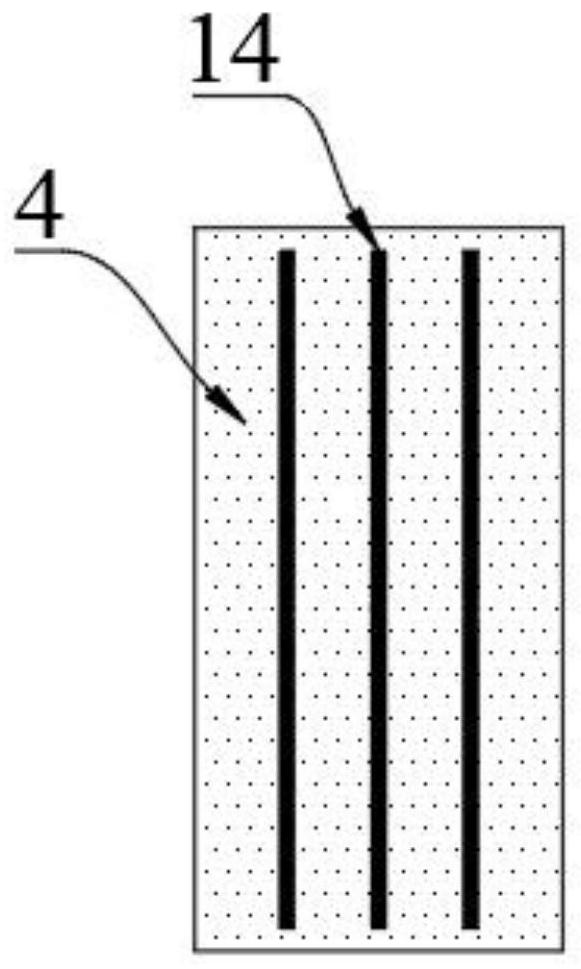

[0019] like Figure 1-3 As shown: the present invention includes a main body superstructure 1 of an earthquake-isolated building and a surrounding site fixture 2, and a leak-proof seismic isolation ditch 3 is vertically arranged between the main body superstructure 1 of the earthquake-isolated building and the surrounding site fixture 2, so that The bottom of the main superstructure 1 of the earthquake-isolation building is provided with an earthquake-isolation bearing and the lower pier 12. The leak-proof earthquake-isolation ditch 3 is provided with an earthquake-isolation ditch retaining wall 5, and the bottom of the main superstructure 1 of the earthquake-isolation building is arranged There is an underground outer wall 11, the lower end of the underground outer wall 11 is provided with a foundation 13, and an earthquake-isolation support is arranged between the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com