Differential bridge type eddy current displacement sensor

A displacement sensor, differential eddy current technology, applied in the direction of instruments, electric devices, electromagnetic means, etc., can solve problems affecting the measurement results of eddy current displacement sensors, detection coil changes, large signal drift, etc., to achieve high resolution, reduce Effect of small probe size and low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

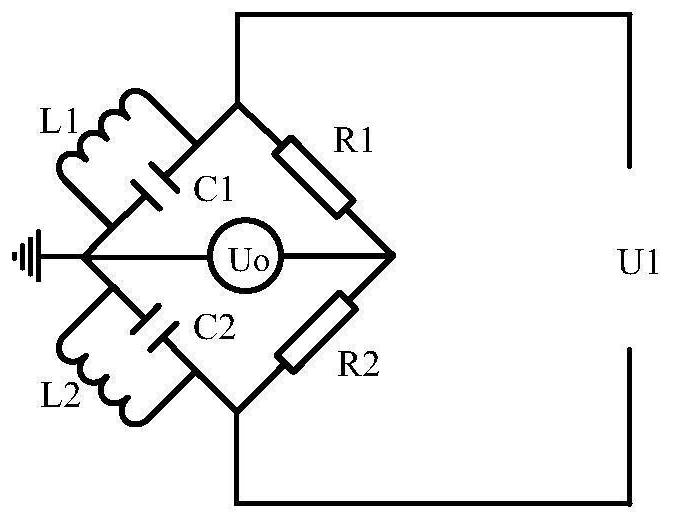

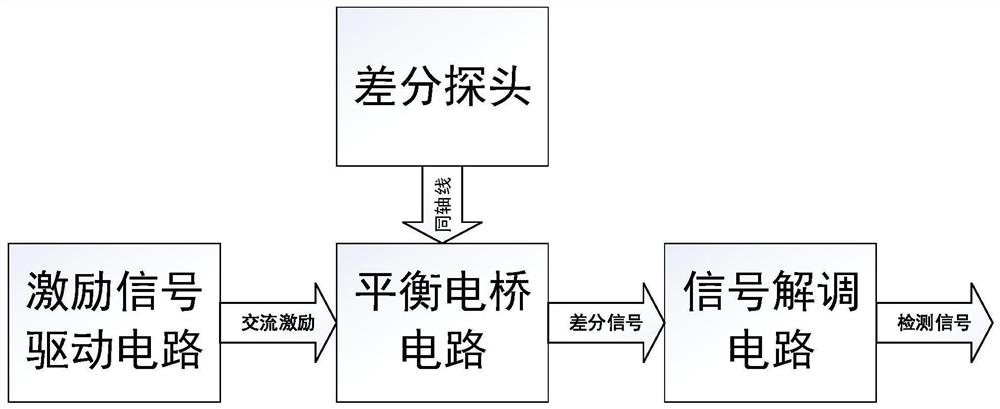

[0011] The present invention is a differential electrostatic eddy current sensor device. It can be configured as a multi-set differential probe and signal processing circuit according to the direction of movement of the object to be measured, and the displacement of the plurality of directions can be measured. It is mainly composed of: signal processing apparatus, a set of differential coaxial and a set of differential vortex detection probes. The signal processing apparatus of the present invention includes: an excitation signal drive circuit, a balanced bridge circuit, and a signal demodulation circuit. The differential eddy current detection probe of the present invention contains only one detection coil without a temperature compensation coil. The detection coil is parallel to the detection surface, and the detection coil is connected by the coaxial wire connection signal processing device. The excitation signal drive circuit generates an alternating excitation to enter the di...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap