Method for simulating microstructure of aluminum alloy welding pool

A welding pool and microstructure technology, applied in special data processing applications, instruments, electrical and digital data processing, etc., can solve problems such as lack of numerical simulation methods, and achieve the effect of saving research costs, accurate and intuitive simulation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

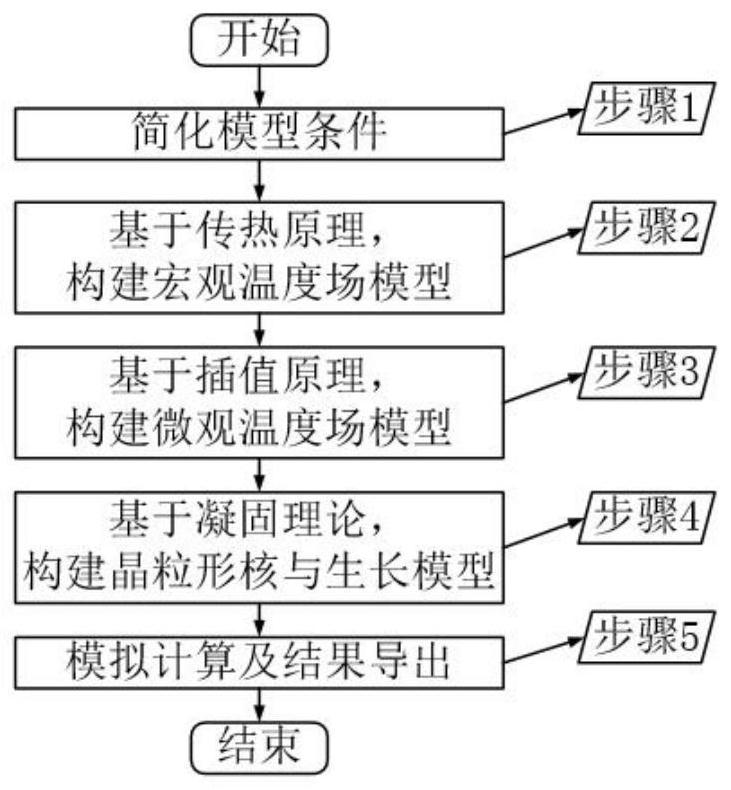

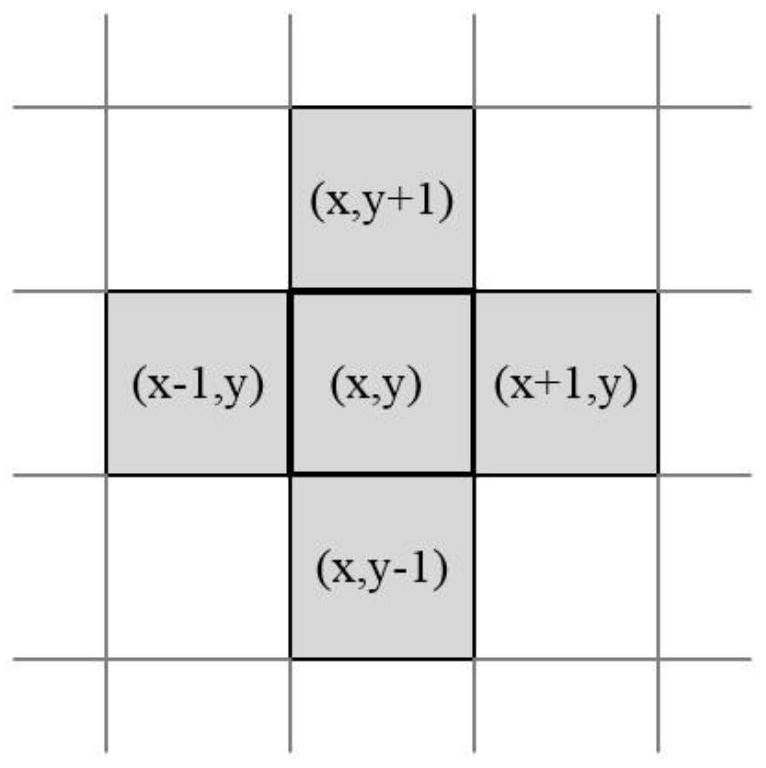

Method used

Image

Examples

Embodiment 1

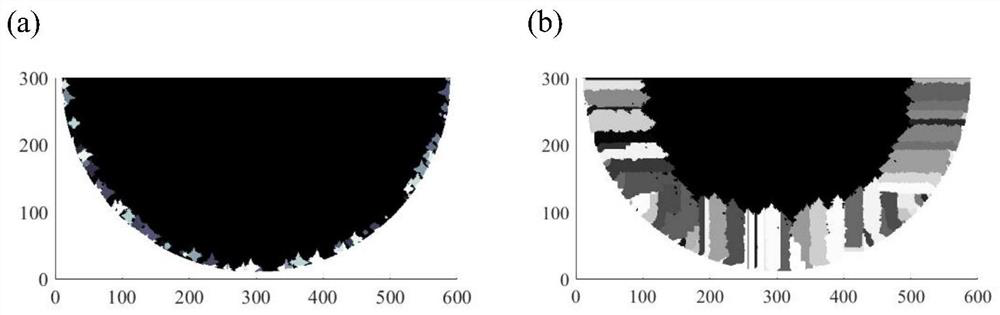

[0124] image 3 a and 3b are the nucleation and growth process of grains at the edge of the weld pool of 1060 aluminum alloy. It can be seen that when the molten pool begins to solidify, crystal grains nucleate at the edge of the molten pool at first. Since the present invention adopts a continuous nucleation model, a large number of crystal nuclei are randomly generated at the edge of the molten pool under the effect of supercooling, such as image 3 as shown in a. As time goes by, grains begin to grow from the edge of the molten pool to the center of the molten pool. Due to the large temperature gradient at this time, the grains grow rapidly to the center of the molten pool in the form of columnar crystals. nuclear production, such as image 3 as shown in b.

Embodiment 2

[0126] Figure 4 a and 4b are the simulation results of CET (columnar-equiaxed) transformation in the center of the weld pool of 1060 aluminum alloy. It can be seen that with the passage of time and the solidification process of the molten pool, the temperature gradient inside the molten pool gradually decreases, and the temperature in the center of the molten pool meets the requirements for equiaxed crystal nucleation and growth, and CET ( Columnar crystals to equiaxed crystals) transition, and the columnar crystals and equiaxed crystals near the center of the molten pool show a tendency to compete for growth. After the molten pool is completely solidified, the microstructure is composed of columnar crystals at the edge and equiaxed crystals in the center.

Embodiment 3

[0128] Figure 5 a and 5b are the simulation results of the microstructure in the molten pool of 5A06 aluminum alloy under different welding process parameters (heat input). It can be seen that with the decrease of welding heat input, the contour of welding pool will decrease accordingly, which will lead to the reduction of the space for grain growth and the trend of grain refinement, from Figure 5 a and Figure 5 From the comparison of b, it can be seen that the columnar grains and equiaxed grains in the molten pool have been significantly refined. Therefore, in the actual aluminum alloy welding process, the welding heat input should be minimized to achieve the purpose of refining the grain structure under the condition of ensuring the connection quality of the welded components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com