Positive plate and battery

A positive electrode sheet and active material layer technology, which is applied in the field of positive electrode sheets and batteries, can solve the problems of reduced structural stability of lithium cobaltate and poor high-temperature cycle of lithium-ion batteries, and achieve the effect of improving high-temperature stability and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

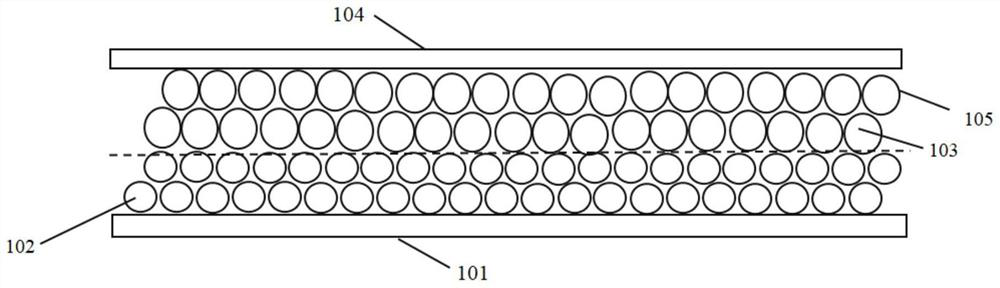

[0081] (1) Two kinds of positive electrode slurries are prepared at the same time: M1 slurry: M1 lithium cobaltate is used as the main material, and M1 slurry is prepared according to 97.5% formula; M2 slurry: M2 lithium cobaltate is used as the main material, according to 97.5% The formula is prepared as M2 slurry; use a double-layer coater to coat two layers at the same time, coat M1 slurry near the aluminum foil area, and coat M2 slurry near the diaphragm area. ):m(M2)=5:5 to complete the coating, and the rolling thickness is 100 μm; the negative electrode sheet can be prepared according to the mass production process.

[0082] (2) After the positive and negative electrode sheets are prepared, they are wound with a ceramic and glue-coated separator with a total thickness of 9 μm, and then the cell production is completed according to the mass production process.

Embodiment 2

[0084] (1) Prepare two positive electrode slurries at the same time: N1 slurry: use N1 lithium cobaltate as the main material, and prepare N1 slurry according to the 97.5% formula; N2 slurry: use N2 lithium cobaltate as the main material, according to 97.5% The formula is prepared as N2 slurry; use a double-layer coater to coat two layers at the same time, apply N1 slurry near the aluminum foil area, and apply N2 slurry near the diaphragm area. ):m(N2)=5:5 to complete the coating, and the rolling thickness is 100 μm; the negative electrode sheet can be prepared according to the mass production process.

[0085] (2) After the positive and negative electrode sheets are prepared, they are wound with a ceramic and glue-coated separator with a total thickness of 9 μm, and then the cell production is completed according to the mass production process.

Embodiment 3

[0087] (1) Two kinds of positive electrode slurries are prepared at the same time: M1 slurry: M1 lithium cobaltate is used as the main material, and M1 slurry is prepared according to 97.5% formula; M2 slurry: M2 lithium cobaltate is used as the main material, according to 97.5% The formula is prepared as M2 slurry; use a double-layer coater to coat two layers at the same time, coat M1 slurry near the aluminum foil area, and coat M2 slurry near the diaphragm area. ):m(M2)=5:5 to complete the coating, and the rolling thickness is 120 μm; the negative electrode sheet can be prepared according to the mass production process.

[0088] (2) After the positive and negative electrode sheets are prepared, they are wound with a ceramic and glue-coated separator with a total thickness of 9 μm, and then the cell production is completed according to the mass production process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com