Concentrate supplement for dairy cow in dry milk perinatal period and preparation process of concentrate supplement

A concentrate supplementary material and perinatal technology, applied in the field of feed, can solve problems such as mixing uniformity and granularity difficult to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

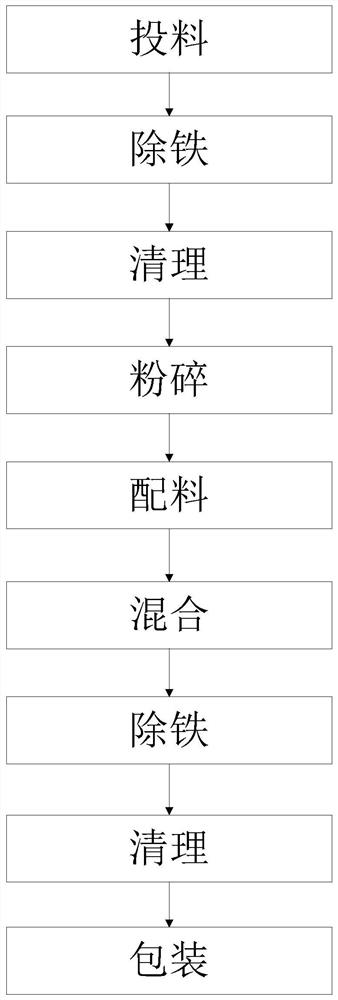

[0046] A preparation process for dairy cow dry milk peripartum concentrate supplement, comprising the following steps:

[0047] S1. Feeding: Prepare protein-based raw materials, energy-based raw materials, yeast-like substances, vitamin E, organic selenium, vitamin A, anion salts, calcium raw materials, trace elements, by-products and other materials for use;

[0048] S2, iron removal: the raw material in step S1 is removed iron through the permanent magnetic cylinder;

[0049] S3. Cleaning: pass the iron-removed material through a 12mm cleaning sieve for cleaning and impurity removal;

[0050] S4, pulverization: the material after above-mentioned cleaning is put into pulverizer and pulverizes, and the sieve sheet of pulverizing sieve is 4.0mm;

[0051] S5. Ingredients: 20-30% of protein-based raw materials, 10-15% of energy-based raw materials, 3-5% of yeast substances, 0.15-0.3% of vitamin E, 0.07-0.2% of organic selenium, and 0.008-0.02% of vitamin A %, 0.4-4.5% of anion ...

Embodiment 1

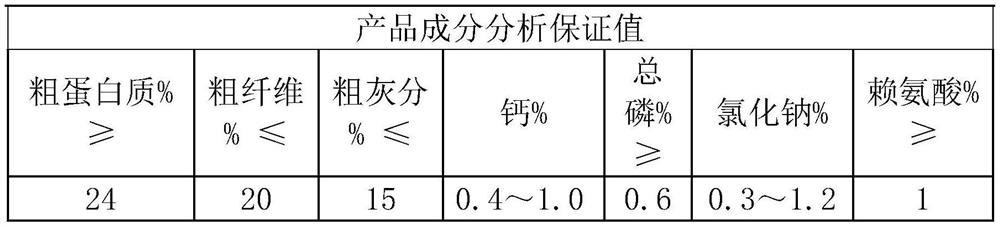

[0059] The invention provides a dry milk perinatal concentrate supplement for dairy cows, which comprises the following raw materials, in mass percentage:

[0060] Protein raw materials (soybean meal, glutamic acid residue, gelatinized urea) 23.6%, energy raw materials (corn, wheat) 12.67%, Yikang XP 3%, vitamin E 0.23%, rich selenium 0.08%, vitamin A 0.01 %, calcium chloride 0.5%, calcium raw material 1.11%, trace elements (including copper, iron, manganese, zinc, sodium, magnesium, iodine, cobalt, selenium, etc.) 1.62%, by-products 50.7% and other substances 6.48%.

[0061] A preparation process for dairy cow dry milk peripartum concentrate supplement, comprising the following steps:

[0062] S1. Feeding: Prepare protein-based raw materials, energy-based raw materials, Yikang XP, vitamin E, rich selenium, vitamin A, calcium chloride, calcium raw materials, trace elements, by-products and other materials for use;

[0063] S2, iron removal: the raw material in step S1 is remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com