An Absorption Heat Pump Rectification System Based on Intermediate Reboiling and Intermediate Condensation

An absorption heat pump and rectification system technology, applied in the field of absorption heat pump rectification systems, can solve problems such as heating energy level mismatch, and achieve the effects of reducing process steam consumption, saving steam, and reducing system waste heat emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

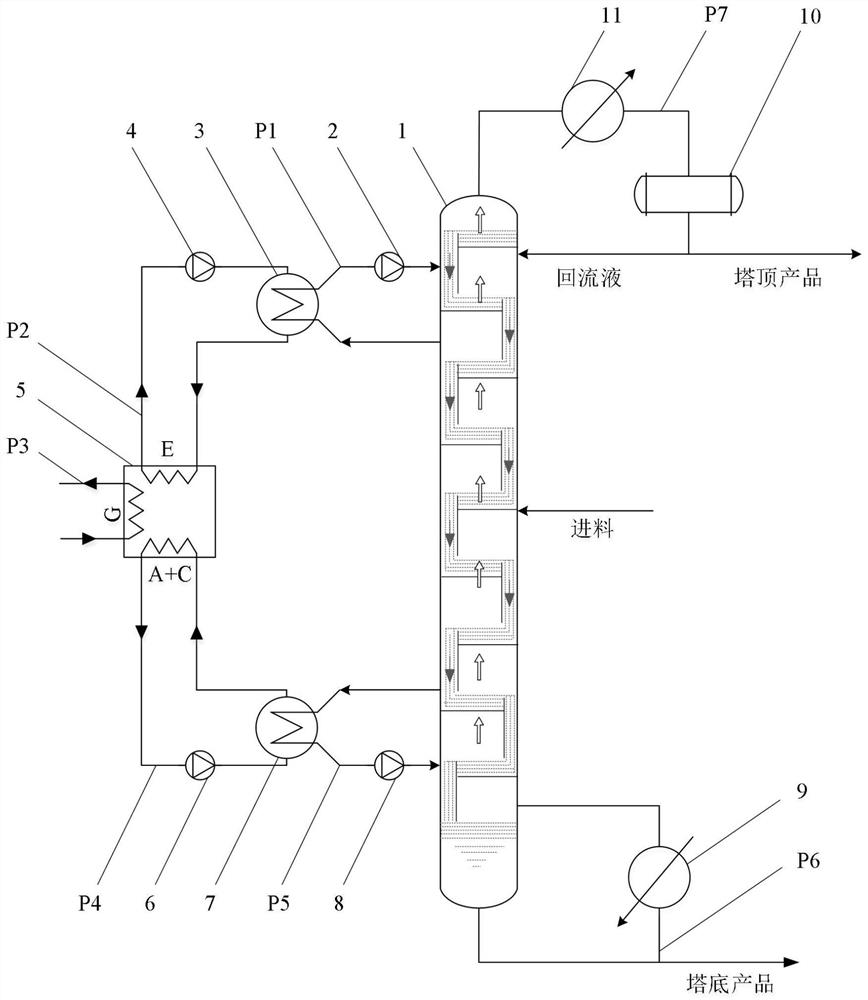

[0021] like figure 1 As shown in the figure, an absorption heat pump rectification system based on intermediate reboiler and intermediate condensation includes a fractionation tower 1, an intermediate condensation heat exchanger 3, an absorption heat pump 5, an intermediate reboiler heat exchanger 7, and a column bottom reboiler. 9. The reflux tank 10 and the overhead condenser 11.

[0022] The rectifying section of the fractionation tower 1 is communicated with one side of the intermediate condensing heat exchanger 3 through the No. 1 material pipeline P1, and the other side of the intermediate condensing heat exchanger 3 is connected to the No. 1 circulating water pipeline P2. The evaporator side of the absorption heat pump 5 is connected, and the rectifying section of the fractionation tower 1, the intermediate condensing heat exchanger 3 and the absorption heat pump 5 are connected in turn to form a top waste heat recovery loop;

[0023] The stripping section of the fract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com