Bismuth molybdate/modified MIL-88A-Fe composite photocatalyst and preparation method thereof

A technology of mil-88a-fe and bismuth molybdate, which is applied in the field of photocatalytic materials, can solve the problem that the photocatalytic activity of bismuth molybdate cannot be improved at the same time, and achieve excellent photocatalytic performance, improve transmission capacity, and improve light absorption performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The second aspect of the embodiment of the present application provides a method for preparing a bismuth molybdate / modified MIL-88A-Fe composite photocatalyst, comprising the following steps:

[0030] S01. MIL-88A-Fe and cerium salt solution are mixed and treated, followed by photodeposition reaction, and then impurity removal treatment and drying treatment are performed to obtain modified MIL-88A-Fe;

[0031] S02. Mix bismuth salt solution, molybdate solution and modified MIL-88A-Fe for hydrothermal reaction, then perform impurity removal treatment and drying treatment to obtain bismuth molybdate / modified MIL-88A-Fe composite photocatalyst Precursor;

[0032] S03. Under a protective atmosphere, the bismuth molybdate / modified MIL-88A-Fe composite photocatalyst precursor is calcined to obtain the bismuth molybdate / modified MIL-88A-Fe composite photocatalyst.

[0033] The preparation method of the bismuth molybdate / modified MIL-88A-Fe composite photocatalyst provided by ...

Embodiment 1

[0071] Bismuth molybdate / modified MIL-88A-Fe composite photocatalyst and its preparation method

[0072] Bismuth molybdate / modified MIL-88A-Fe composite photocatalyst

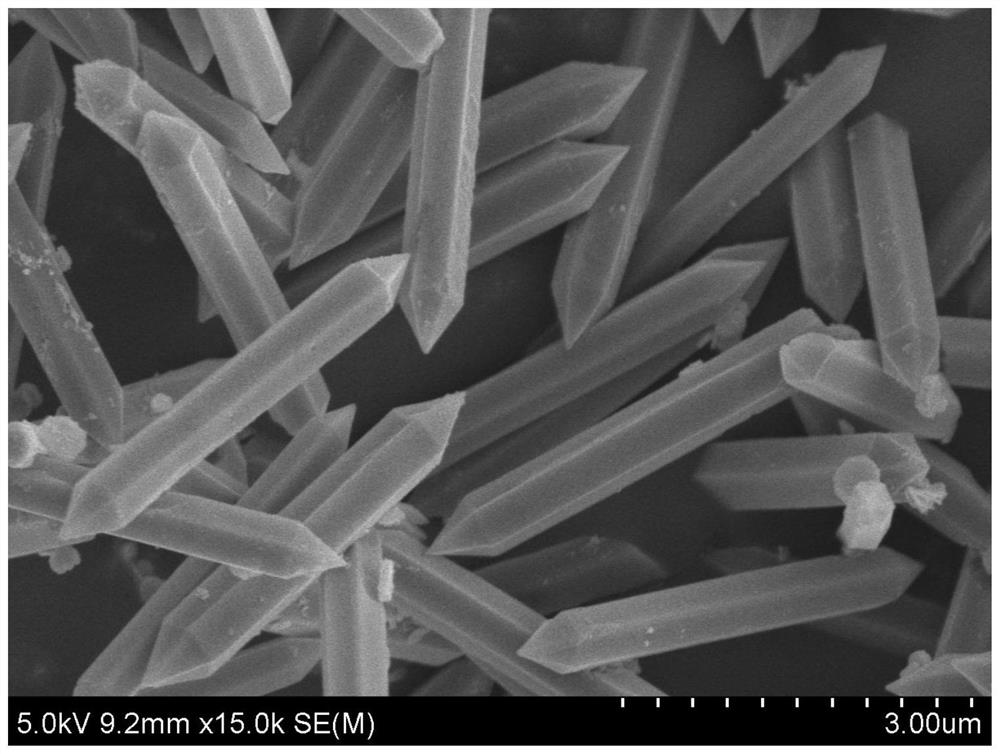

[0073] Bismuth molybdate / modified MIL-88A-Fe composite photocatalyst is prepared by the method of the following example 1, and its SEM figure is as follows figure 1 As shown, the bismuth molybdate / modified MIL-88A-Fe composite photocatalyst uses the modified MIL-88A-Fe with needle-like structure as the carrier, and the bismuth molybdate with the sheet structure is loaded on the surface of the modified MIL-88A-Fe; Among them, the modified MIL-88A-Fe is the MIL-88A-Fe with cerium deposited on the surface, the bismuth molybdate is the bismuth molybdate with oxygen vacancies on the surface, and the size of the bismuth molybdate is 20 nanometers; the modified MIL-88A -Fe has a length of 5-7 micrometers and a width of 0.8-1 micrometer.

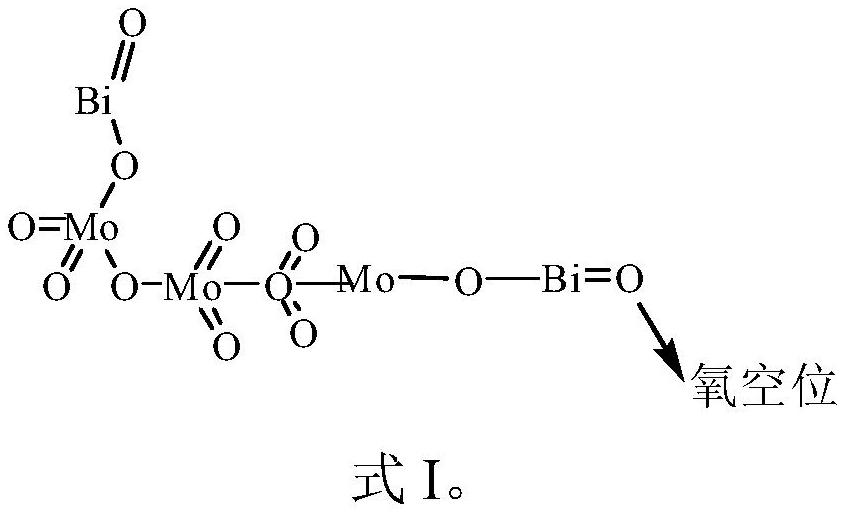

[0074] Wherein, in the bismuth molybdate / modified MIL-88A-Fe composite photo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com